Monitoring and controlling room pressure in laboratory and healthcare settings can do more than just ensure directional airflow (positive or negative pressure rooms). Proper room pressure also contributes to saving energy. Overpressure or under-pressure scenarios mean that airflow, or even temperature control, are not optimal.

Setra Blog

Mike Soper

Recent Posts

Operating Rooms consume a great deal of energy, considering the high airflow requirements needed, bright lighting, and significant plug load from patient care equipment. There are, however, strategies to conserve energy and still meet the stringent safety requirements of maintaining positive room pressure. Two conditions need to be met to enable OR energy savings. The first is a method to trigger occupied and unoccupied states. And the second is to act on that state change to setback both temperature and airflow.

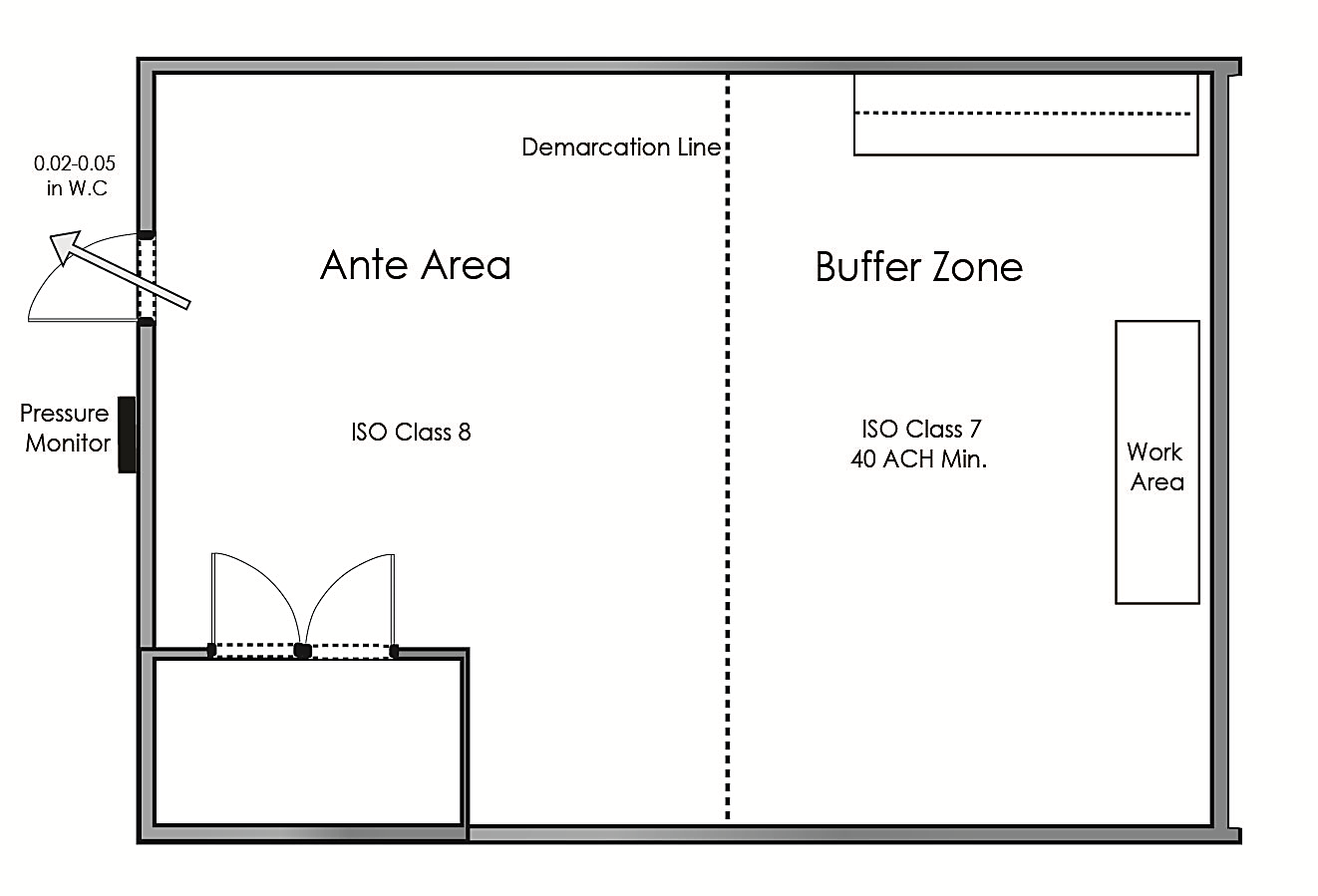

There are several techniques for managing safe and reliable pressurized rooms in healthcare and laboratory applications. When anterooms are present, such as those used for isolation rooms and pharmacies, it is not always clear how the anteroom should be pressurized in relation to the adjoining room and hallway.

Engineering proper HVAC systems for critical environments often involves distinct areas of room pressure control and directional airflow. An anteroom between a primary room and corridor ensures a safe airflow buffer zone between the controlled pressurized space and an unclean area. The two spaces are separated by a completely walled area with a door. However, in some applications an ante area without walls or a door can achieve the same effect.

Protective Environment (PE) rooms are hospital rooms designed to protect a high-risk immunocompromised patient from human and environmental airborne pathogens. These are positive pressure rooms intended to keep patients safe during recovery from cancer treatment or stem-cell transplant.

Airborne Infection Isolation (AII) rooms, commonly called negative pressure rooms, are single-occupancy patient care spaces designed to isolate airborne pathogens to a safe containment area. AII rooms are a specialized application of a hospital’s HVAC system, where the airflow supplied into the room is balanced with exhaust airflow to create at least -0.01” WC negative differential pressure with respect to an adjacent space, usually the hallway or an anteroom. In simple terms, this provides a gentle flow of air under a closed doorway and into the room so that no airborne particulates escape into nursing staff or public areas. Exhaust from these rooms is not recirculated in the HVAC system. Instead, exhaust air typically moves in dedicated ductwork to ventilation stacks on the rooftop, where atmospheric air provides sufficient dilution to make the resulting air safe.

There is no guarantee of a perfect, contaminant free cleanroom. However by adhering to room pressure requirements, proper gowning procedures and by understanding the origins of the contaminants, users can minimize contamination risk to ensure safe testing and manufacturing environment. These are some of the things you may not have realized can compromise a cleanroom, and some possible ways to reduce the contamination of the source.

Hospital staffs face a barrage of beeping devices daily while caring for patients. Alarm fatigue, as it’s known, can cause staff to ignore alarms, especially if different devices have similar sounds or frequencies. Nuisance alarms are those sounds that do not represent a danger to the patient, but come from devices that cannot otherwise be configured to stop the alarm from sounding when a situation is neither important nor urgent.

Pressure Sensor Installation: In the Wall or In the Ceiling?

The landscape of room pressure monitors is diverse, with many different options of product design from various manufacturers. One of the basic choices in product design is whether to include the differential pressure transducer on-board with the touch screen, or external in the ceiling or interstitial space. There are pros and cons for each approach, depending mostly on the preference of the A&E firm or customer.

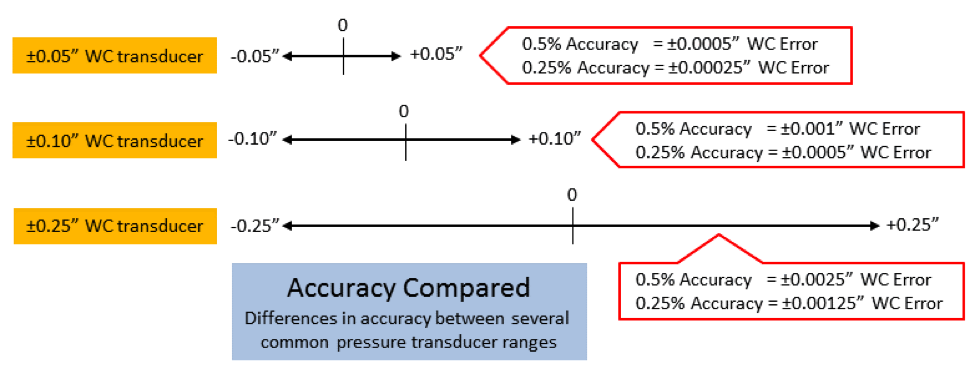

A frequent question asked about room pressure monitoring applications is “how much sensor accuracy do I need?” The most common thought is to order the most accurate sensor available. For a moment, consider all things are equal with regard to price. Is the best accuracy the best choice? Not always. It depends on the application.

Subscribe to Our Blog!

Topics

- Critical Environments (182)

- HVAC/R (179)

- General Industrial (153)

- Building Automation (134)

- General Industrial OEM (92)

- Energy Management (85)

- Test and Measurement (66)

- HVAC/R OEM (58)

- Barometric (44)

- Alternative Fuels (42)

- Medical (40)

- Process/Mfg Tank Level (40)

- Water and Wastewater (39)

- OHV (38)

- Oil and Gas (35)

- Industrial Vacuum (29)

- Calibration (25)

- Semiconductor (25)

- Particle Counting (18)

- Cleanroom Monitoring (17)

- Room Pressure Monitoring (16)

- Trade Show (12)

- cleanroom environment (12)

- Scales (11)

- Environmental Monitoring (10)

- Power Monitoring (10)

- Healthcare (9)

- Power Meters (9)

- Software (9)

- cleanroom monitoring systems (9)

- Case Study (8)

- critical environment technologies (8)

- Humidity (7)

- data centers (7)

- particle counter (6)

- pressure transducers (6)

- LITE room pressure monitor (5)

- hardware and software cleanroom monitoring systems (5)

- setra lite (5)

- Compliance (3)

- Video (3)

- hospital spaces (3)

- FAQ & Troubleshooting (2)

- Monitoring Compounding Pharmacies (2)

- Semiconductor Manufacturing (2)

- agencies that monitor pharmacies (2)

- energy (2)

- hvac (2)

- laboratories (2)

- monitor compound pharmacy (2)

- protected environment (2)

- regulatory compliance (2)

- setra lite features (2)

- usp 797 (2)

- Current Sensors and Transducers (1)

- Current Transformers (1)

- Pressure (1)

- aerospace cleanrooms (1)

- cems (1)

- digital transformation (1)

- ipv6 multicast (1)

- ipv6 multicast address (1)

- ipv6 multicast address range (1)

- isolation room pressure monitoring (1)

- multicast address ipv6 (1)

- multicast ipv6 (1)

- operating room (1)

- pharma 4.0 (1)

- pressure sensor (1)

- pressure transducer companies (1)

- semi conductor (1)

- sensors and transducers (1)

- setra pressure transducers (1)

- submetering (1)

- sustainability (1)

- temperature monitor (1)

- temperature monitoring for pharmacies (1)

- transducers (1)

- usp 800 (1)

- water (1)

- what does hvac stand for (1)

- what is a transducer (1)

- what is hvac (1)