There are numerous environmental factors that can interfere with the performance of a pressure transducer. Two commonly overlooked factors are shock and vibration. Knowing the system where the pressure transducer is installed can help avoid high shock and vibration conditions, minimizing premature failure of your instrumentation.

Setra Blog

Tom Lish

Recent Posts

Hysteresis Defined

According to Merriam-Webster, hysteresis is the “lagging of a physical effect on a body behind its cause (as behind changed forces and conditions)”. When outside forces act on an object, that object will either immediately spring back to its original state, or more likely, it will somehow change or exhibit properties from previous deformations.

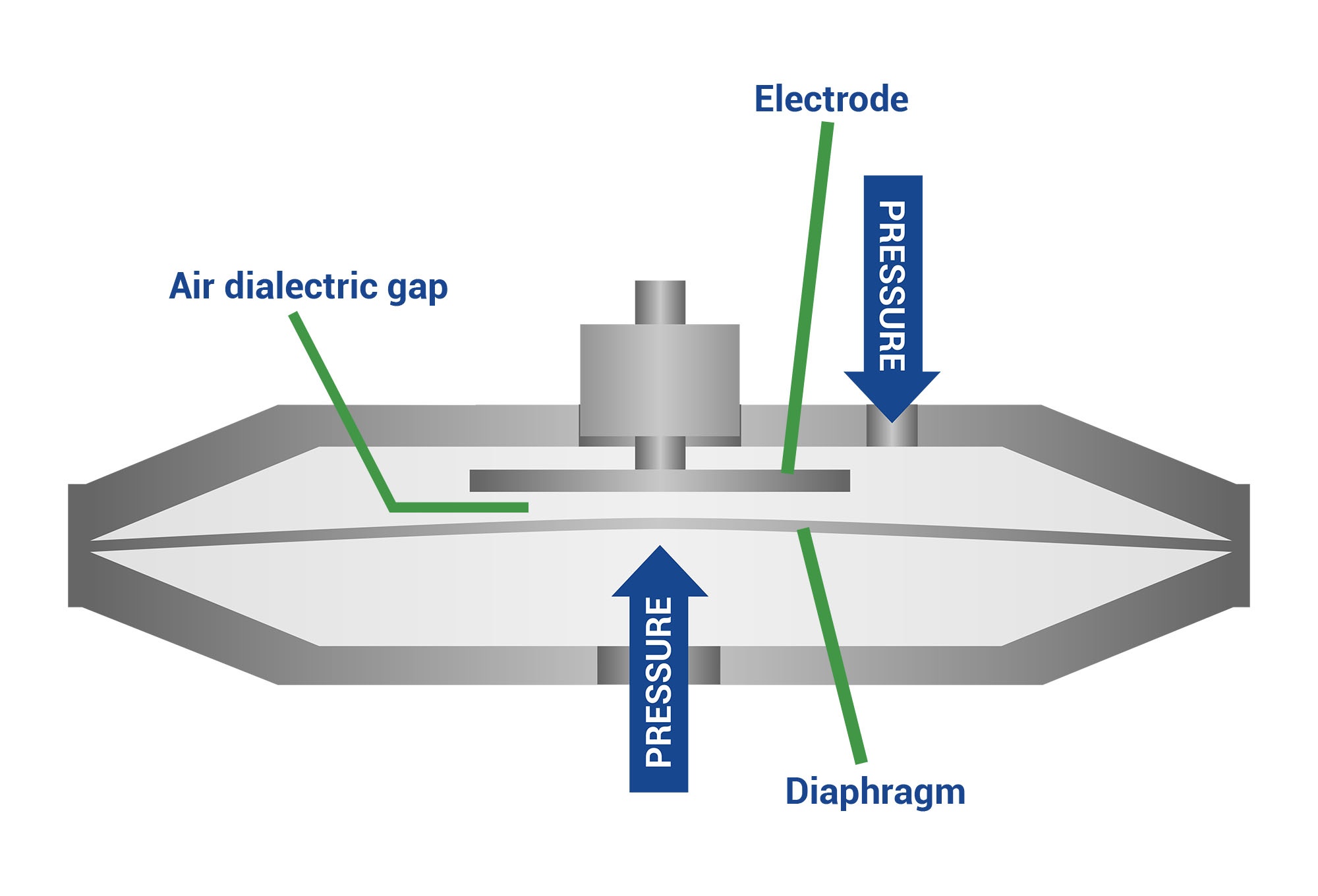

Setra is best known for pioneering the variable capacitance principle, the technological innovation behind capacitance-based pressure transducers. Variable capacitance transducers demonstrate industry-leading accuracy especially in low pressure HVAC and critical care applications with accuracies as high as ±0.25” water column (±0.009 PSI).

In many pressure sensing applications, high accuracy is a must-have. Whether you’re working with thousands of PSI or only a quarter inch of water column, the most demanding jobs require the best tools available. While there are many types of pressure sensing devices on the market, none quite match variable capacitance transducers in terms of accuracy and quality.

As of July 22, the RoHS exemption for industrial monitoring and control instruments will end. Non- compliant product cannot be CE marked and sold in the European Union or to customers who otherwise require the CE mark.

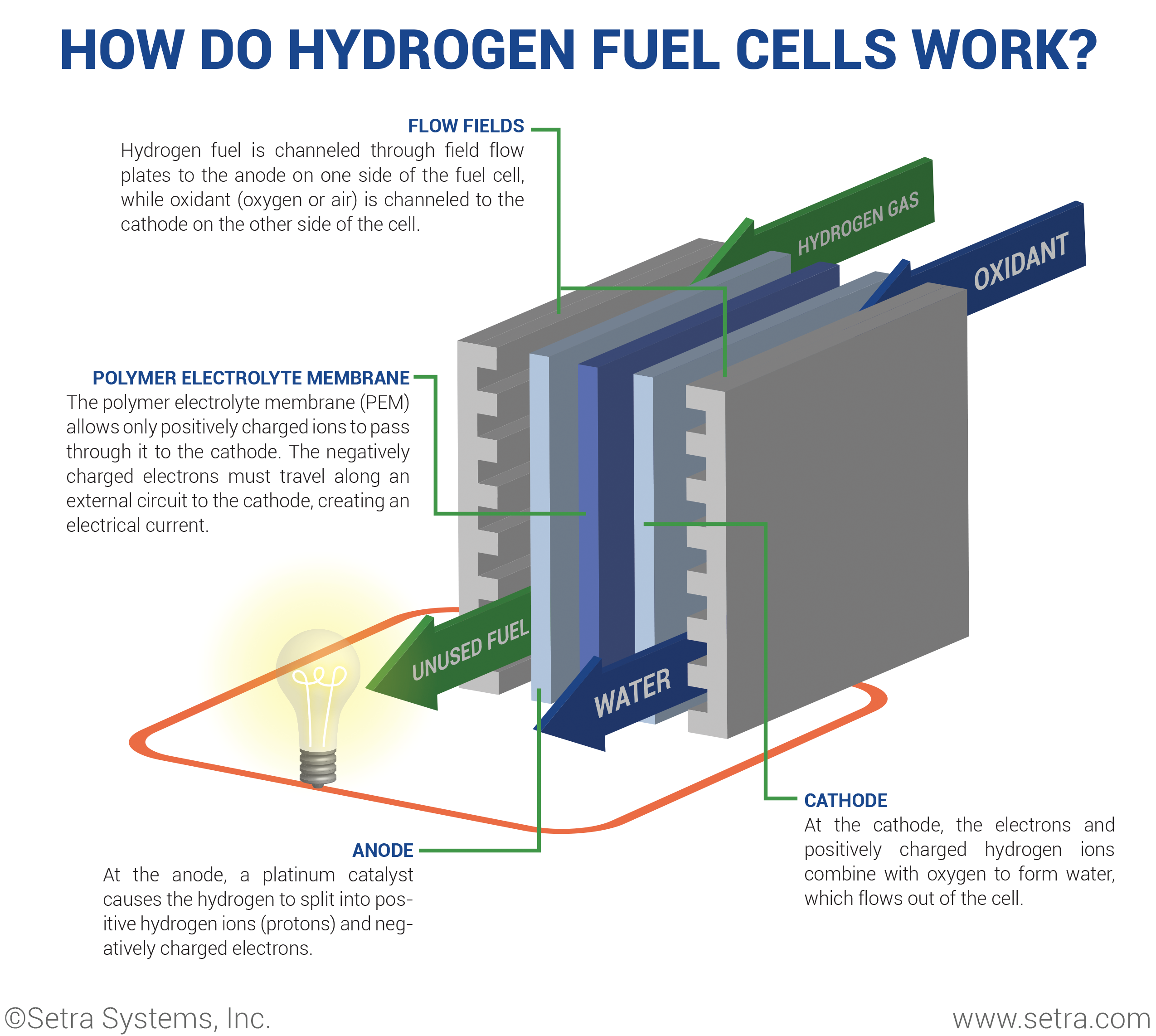

Although hydrogen is in its infancy as a fuel source, its future is incredibly bright. The technology behind hydrogen fuel cells is improving daily and its viability as a replacement to the internal combustion engine seems likely. Hydrogen is already being used in specialty vehicles such as forklifts and buses, and it’s only a matter of time before infrastructure is in place to serve the consumer automotive market. Why do hydrogen fuel cells have such great appeal? Because their only byproducts are heat and water vapor, making hydrogen fuel cells a truly zero-emission locomotive technology.

Capacitance is the ability of an object to hold an electrical charge. Capacitors are components in an electrical circuit that can store a charge and are considered one of the three fundamental electronic components along with inductors and resistors.

Simply put, barometric pressure is the measurement of air pressure in the atmosphere, specifically the measurement of the weight exerted by air molecules at a given point on Earth. Barometric pressure changes constantly and is always different depending on where the reading takes place.

In the pressure sensing industry there are many different sensor technologies, but all sensors can be broken down into two classifications; oil-filled, non-oil filled. An oil-filled sensor refers to a sensor that uses oil as a transfer medium between a diaphragm and the sensing element. Oil-filled sensors appeal to many manufacturing applications due to its material compatibility, low cost, and ease of implementation. Although these sensors are becoming a standard, there are several drawbacks to selecting an oil-filled sensor over a non-oil filled sensor.

Whether you are looking for a solution to solve a tank level measurement issue to a building or trying to monitor a process tank within your factory, the proper tank level is extremely important to the success of your project. There are countless applications across many industries that with a few simple steps can ensure that you can meet the needs of your project.

Subscribe to Our Blog!

Topics

- Critical Environments (182)

- HVAC/R (179)

- General Industrial (153)

- Building Automation (134)

- General Industrial OEM (92)

- Energy Management (85)

- Test and Measurement (66)

- HVAC/R OEM (58)

- Barometric (44)

- Alternative Fuels (42)

- Medical (40)

- Process/Mfg Tank Level (40)

- Water and Wastewater (39)

- OHV (38)

- Oil and Gas (35)

- Industrial Vacuum (29)

- Calibration (25)

- Semiconductor (25)

- Particle Counting (18)

- Cleanroom Monitoring (17)

- Room Pressure Monitoring (16)

- Trade Show (12)

- cleanroom environment (12)

- Scales (11)

- Environmental Monitoring (10)

- Power Monitoring (10)

- Healthcare (9)

- Power Meters (9)

- Software (9)

- cleanroom monitoring systems (9)

- Case Study (8)

- critical environment technologies (8)

- Humidity (7)

- data centers (7)

- particle counter (6)

- pressure transducers (6)

- LITE room pressure monitor (5)

- hardware and software cleanroom monitoring systems (5)

- setra lite (5)

- Compliance (3)

- Video (3)

- hospital spaces (3)

- FAQ & Troubleshooting (2)

- Monitoring Compounding Pharmacies (2)

- Semiconductor Manufacturing (2)

- agencies that monitor pharmacies (2)

- energy (2)

- hvac (2)

- laboratories (2)

- monitor compound pharmacy (2)

- protected environment (2)

- regulatory compliance (2)

- setra lite features (2)

- usp 797 (2)

- Current Sensors and Transducers (1)

- Current Transformers (1)

- Pressure (1)

- aerospace cleanrooms (1)

- cems (1)

- digital transformation (1)

- ipv6 multicast (1)

- ipv6 multicast address (1)

- ipv6 multicast address range (1)

- isolation room pressure monitoring (1)

- multicast address ipv6 (1)

- multicast ipv6 (1)

- operating room (1)

- pharma 4.0 (1)

- pressure sensor (1)

- pressure transducer companies (1)

- semi conductor (1)

- sensors and transducers (1)

- setra pressure transducers (1)

- submetering (1)

- sustainability (1)

- temperature monitor (1)

- temperature monitoring for pharmacies (1)

- transducers (1)

- usp 800 (1)

- water (1)

- what does hvac stand for (1)

- what is a transducer (1)

- what is hvac (1)