Selecting the optimal method to measure liquid tank level is an extremely important decision when starting your project. Making the right choice helps ensure that both vented aboveground and in-ground tanks as well as pressurized tanks work properly. This means that homeowners will receive water for drinking, water will be available to fight fires in remote residential areas, manufacturers will maintain

Setra Blog

Tom Lish

Recent Posts

One of the biggest concerns after pressure transducers have been installed is knowing how accurate the results will be over time. As a result pressure transducers are replaced more often than necessary or are calibrated with outdated technology. Low-pressure transducers used in critical applications require calibration after extended use to ensure

Hydrogen is the most plentiful element in the universe and is now becoming a viable fuel source for many applications. Due to its efficiency and low environmental impact, the interest in hydrogen being the "fuel of the future" continues to grow. The many features and benefits to hydrogen make it an ideal choice for many up-and-coming industrial applications. A few of the more common applications are:

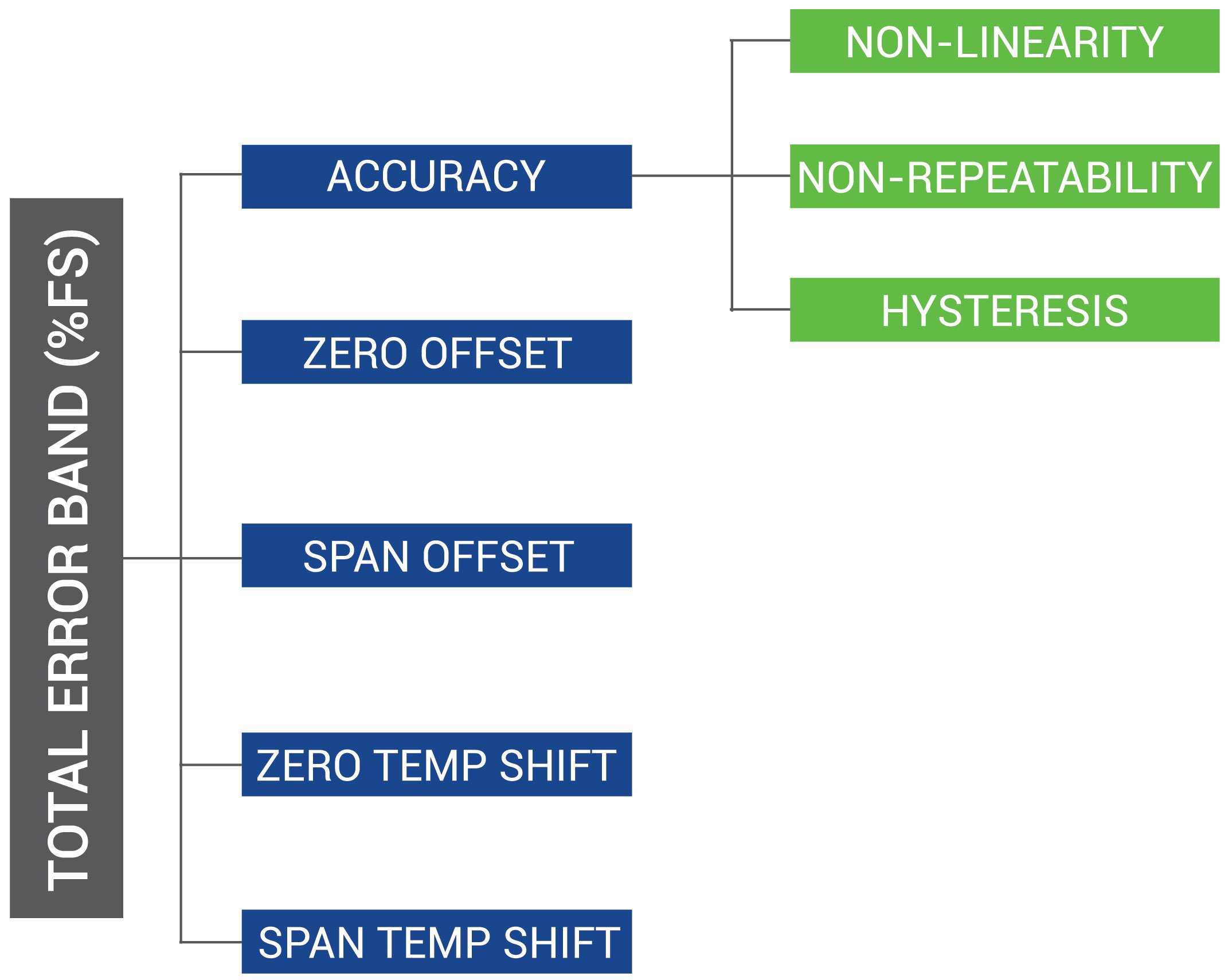

Total Error Band (TEB) is a measurement of worst case error; it is the most comprehensive and concise measurement of a sensors true accuracy over a compensated temperature range. TEB is extremely important to know when trying to determine how well a sensor will work within a particular design system. By calculating TEB you'll be able to understand the different possibilities for error. Formulating TEB can be tricky if you don't have the right inputs readily available.

Proof pressure and burst pressure are critical specifications for pressure sensors and other pressure-related devices, but they serve different purposes.

Typically, there are many different pressure specifications indicated on a pressure transducer data sheet. Interestingly enough, two of the most important pressure specifications are often easily overlooked; proof and burst pressure. Selecting a pressure transducer without noticing these pressure ranges is one of the top reasons for transducer failure. Both pressure specifications are considered to act as an upper limit for the device’s operating range. So, what exactly is the difference between proof and burst pressure?

Low pressure measurements are required in various applications such as air flow, static duct and cleanroom pressures in HVAC and energy management systems (EMS). Other applications include use in medical instrumentation, environmental pollution control, boil combustion efficiency and a wide variety of research and development requirements. Although the focus will center mainly on air flow and pressure, the same principles

Selecting the correct accuracy for your sensing application is only half the challenge; being able to maintain that level of accuracy over time is equally important. To clarify on what we mean by the accuracy, we define it as the maximum difference between the actual value and the sensor’s output (in terms of %FS). Maintaining a sensor’s accuracy is difficult. Users face the issue of a sensor going out of tolerance and are unaware of the root causes. Depending on the level of accuracy required by the application, the consequences of imprecise accuracy can vary. For example, an isolation room requires a high level of accuracy to protect both the patients’ and medical professionals’ health and safety. If a room pressure monitor provided doctors and nurses with an incorrect sensor output, they can make incorrect judgments such as walking into a improperly labeled space. Based off of the inaccurate sensor output, doctors and nurses can also accidently release harmful contaminants into the rest of the hospital without a proper alarm notification.

Like we mentioned in our previous post, capacitance is used everywhere. Capacitance affects your day-to-day living without you even realizing it. It is difficult nowadays to find an application/industry that functions without, or is not impacted by, capacitance pressure transducers. When compared to other types of pressure sensors, capacitance pressure transducers have earned a reputation of high accuracy and long term stability, thus making it the primary choice for many of these applications:

June 27, 2016

What is the difference between an absolute sensor and a gauge sensor and when should I use each?

When selecting an absolute, gauge or differential pressure sensor, the lines between absolute and gauge can be blurred. There are many differences between the two regarding performance and application. Therefore, it is essential to determine whether you need a gauge or absolute reference for measuring pressure. Like selecting a pressure range, it is important to select the correct pressure measurement to avoid errors in your measurement, especially when requiring a low range device.

Although there are a variety of methods for leak detection, the most common is pressure decay. Other methods can be time consuming and costly, whereas pressure decay leak detection is a simple test that's sensitive to very small leaks. This method is ideal for high-volume industries that require quick accurate tests within their facility. By pressurizing the unit under test (UUT) and then removing it from the pressure source, any detection of pressure loss is a result of a leak within the UUT. Before performing a pressure decay leak detection test, make sure your system is properly setup. After the system is setup, follow the below steps to test the UUT with a differential pressure transducer.

Subscribe to Our Blog!

Topics

- Critical Environments (182)

- HVAC/R (179)

- General Industrial (153)

- Building Automation (134)

- General Industrial OEM (92)

- Energy Management (85)

- Test and Measurement (66)

- HVAC/R OEM (58)

- Barometric (44)

- Alternative Fuels (42)

- Medical (40)

- Process/Mfg Tank Level (40)

- Water and Wastewater (39)

- OHV (38)

- Oil and Gas (35)

- Industrial Vacuum (29)

- Calibration (25)

- Semiconductor (25)

- Particle Counting (20)

- Cleanroom Monitoring (17)

- Room Pressure Monitoring (16)

- Trade Show (12)

- cleanroom environment (12)

- Scales (11)

- Environmental Monitoring (10)

- Power Monitoring (10)

- Healthcare (9)

- Power Meters (9)

- Software (9)

- cleanroom monitoring systems (9)

- Case Study (8)

- critical environment technologies (8)

- data centers (8)

- Humidity (7)

- particle counter (6)

- pressure transducers (6)

- LITE room pressure monitor (5)

- hardware and software cleanroom monitoring systems (5)

- setra lite (5)

- Compliance (3)

- Video (3)

- hospital spaces (3)

- FAQ & Troubleshooting (2)

- Monitoring Compounding Pharmacies (2)

- Semiconductor Manufacturing (2)

- agencies that monitor pharmacies (2)

- energy (2)

- hvac (2)

- laboratories (2)

- monitor compound pharmacy (2)

- protected environment (2)

- regulatory compliance (2)

- setra lite features (2)

- usp 797 (2)

- Current Sensors and Transducers (1)

- Current Transformers (1)

- Lithium-Ion Battery (1)

- Pressure (1)

- aerospace cleanrooms (1)

- cems (1)

- digital transformation (1)

- ipv6 multicast (1)

- ipv6 multicast address (1)

- ipv6 multicast address range (1)

- isolation room pressure monitoring (1)

- multicast address ipv6 (1)

- multicast ipv6 (1)

- operating room (1)

- pharma 4.0 (1)

- pressure sensor (1)

- pressure transducer companies (1)

- semi conductor (1)

- sensors and transducers (1)

- setra pressure transducers (1)

- submetering (1)

- sustainability (1)

- temperature monitor (1)

- temperature monitoring for pharmacies (1)

- transducers (1)

- usp 800 (1)

- water (1)

- what does hvac stand for (1)

- what is a transducer (1)

- what is hvac (1)