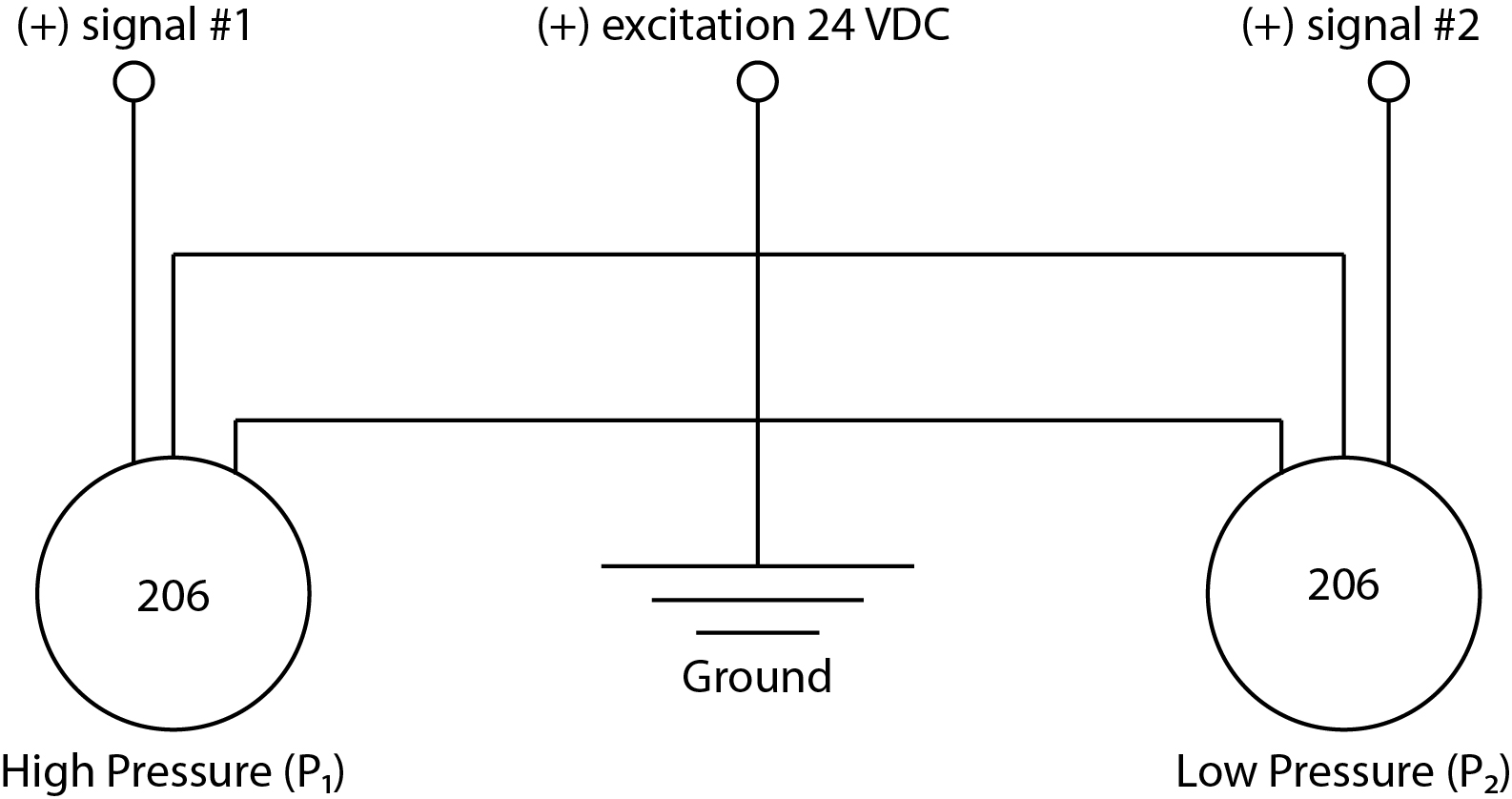

Many of the following technical specifications appear on datasheets for pressure transducers and similar devices. Here we review their technical definitions and relationships.

Root Sum Squares (RSS): accuracy of a pressure transducer is calculated by taking the square root of non-linearity + hysteresis + non-repeatability.