Demand based ventilation is an important aspect of HVAC design and control. Traditionally, demand based ventilation is done with CO2 sensors that look for a rise in CO2 and respond by increasing the air change rate to bring in more fresh air. To monitor and perform demand based ventilation, there is a control loop between the CO2 sensor and the HVAC control system. This type of ventilation is especially necessary for larger rooms where people gather, such as:

- Conference rooms

- Function rooms

- Auditoriums

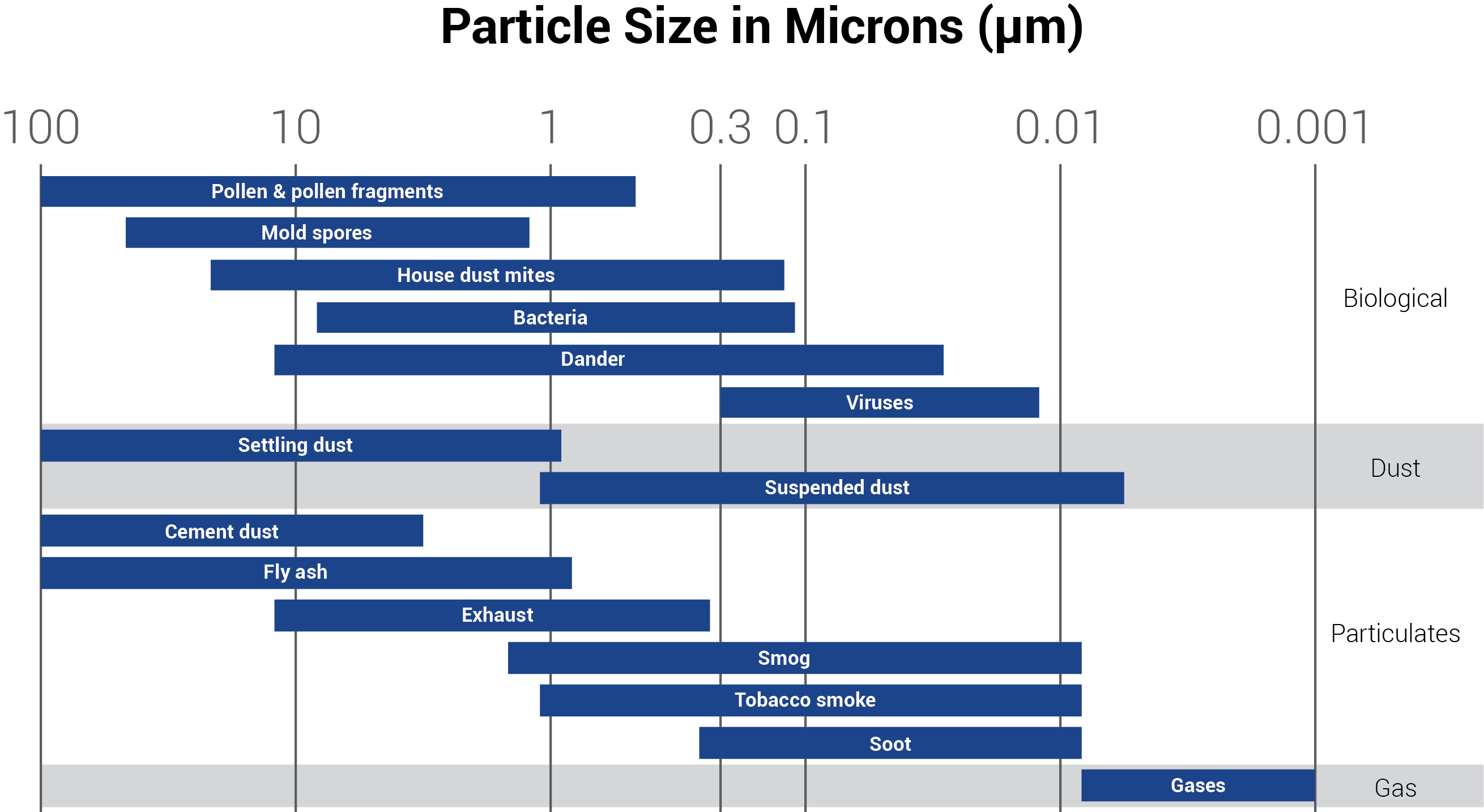

An innovative way to leverage the benefits of demand based ventilation without CO2 sensors is to use particle counters. When closer scrutiny of particulates in the air is required, this technique can be deployed. A higher number of particulates in the air of a certain size can trigger an action just as a detection of higher CO2 would. Like traditional demand based ventilation, this action could be a HEPA filter change, increase in air change rate, or alarm sequences, for example. This particulate trigger can be valuable for reacting to and improving air quality concerns. This kind of demand response ventilation is useful in cleanrooms, research facilities, hospitals, smaller outpatient facilities, and even large rooms in schools and educational buildings.

Trending particle counts over time allows for close monitoring of Indoor Air Quality (IAQ) and subsequent increased air changes in response to the data. Setra’s particle counters provide the ability to monitor particle counts of certain sizes and seamlessly integrate with facility monitoring systems, making it easy to set up demand based ventilation with particle counters for better indoor air quality control.