When installing a pressure transducer system, selecting a power supply may not be one of the first things that comes to your mind. Since a single power supply can be used to power multiple pressure transducers, many regard it as a non-vital task. Nonetheless, it is essential to have the proper configurations between the power source and devices in order for all components to communicate properly and to avoid receiving inaccurate data. Here are some of the best practices we found for using a single power supply to power multiple devices.

- Check if the power supply can provide the required excitation voltage as well as the required amperage for the pressure transducers

- Confirm if the transducer requires AC or DC voltage

- Confirm if the transducer requires an isolated power supply

- The number of transducers that can be used with a single power supply is determined by the current draw of each transducer and the current output of the supply source.

- The sum of the current draw of the transducers cannot exceed the total current output of the power supply.

- For example, if you have 10 transducers drawing 24 mA, you will need a power supply of at least 240 mA

- Avoid miswiring by referring to the specific transducer wiring diagram

- Although it is not preferred, if using batteries or solar power as a power source, use lower consumption pressure transducers

- Have a separate power supply for your controller than you have for your transducers to eliminate electrical noise

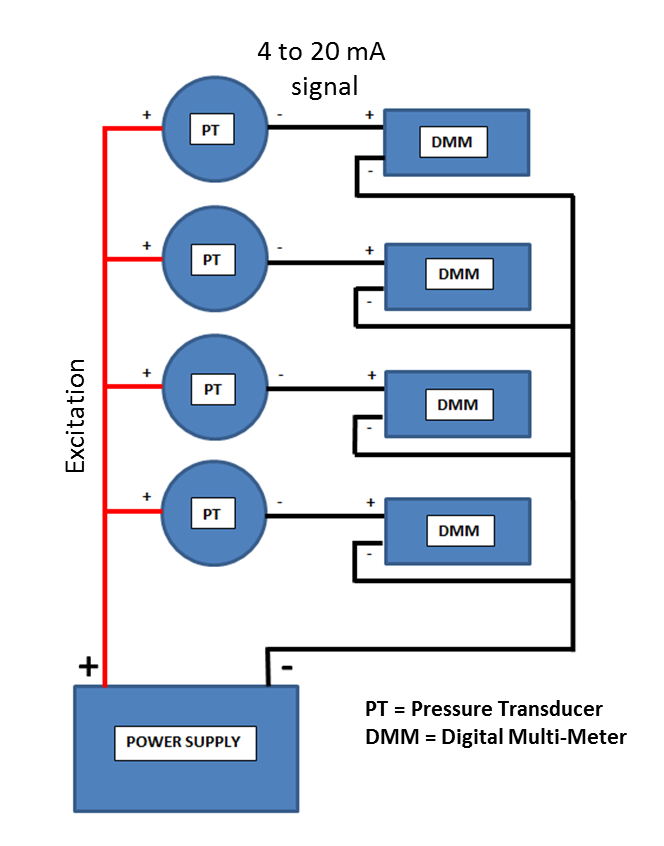

- You can have multiple power supplies for multiple pressure transducers; however ensuring compatibility becomes more difficult as the number of components increases. The diagram above shows an example of possible wiring configuration of four 4 to 20 mA transducers and AMP meters to monitor outputs with a single power supply

CLICK HERE to learn how to select a pressure transducer.