Until recently, there was no standard industry network protocol for building automation, and users had to choose between many different systems from different manufacturers. Proprietary communications were a result of no off-the shelf communication solution. Today, we have reached a place where there are three inter-operable standard network protocols to choose from: BACnet, LonWorks and Modbus. All three are widely used, and according to a Building Operating Management survey in 2011, 62% of respondents had at least one BACnet application; for LonWorks the percentage was 40%, while for Modbus the number was 30%.

Setra Blog

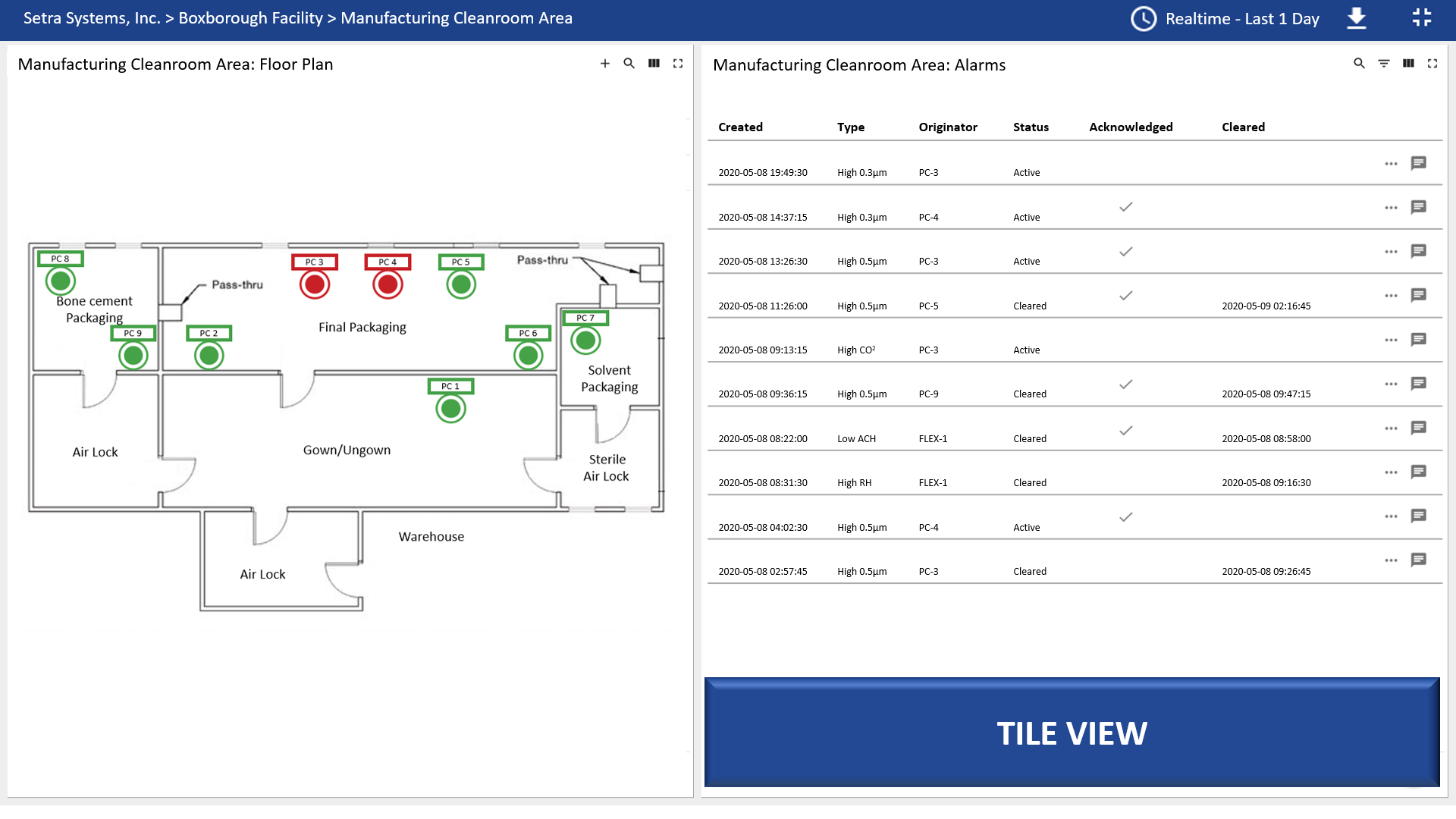

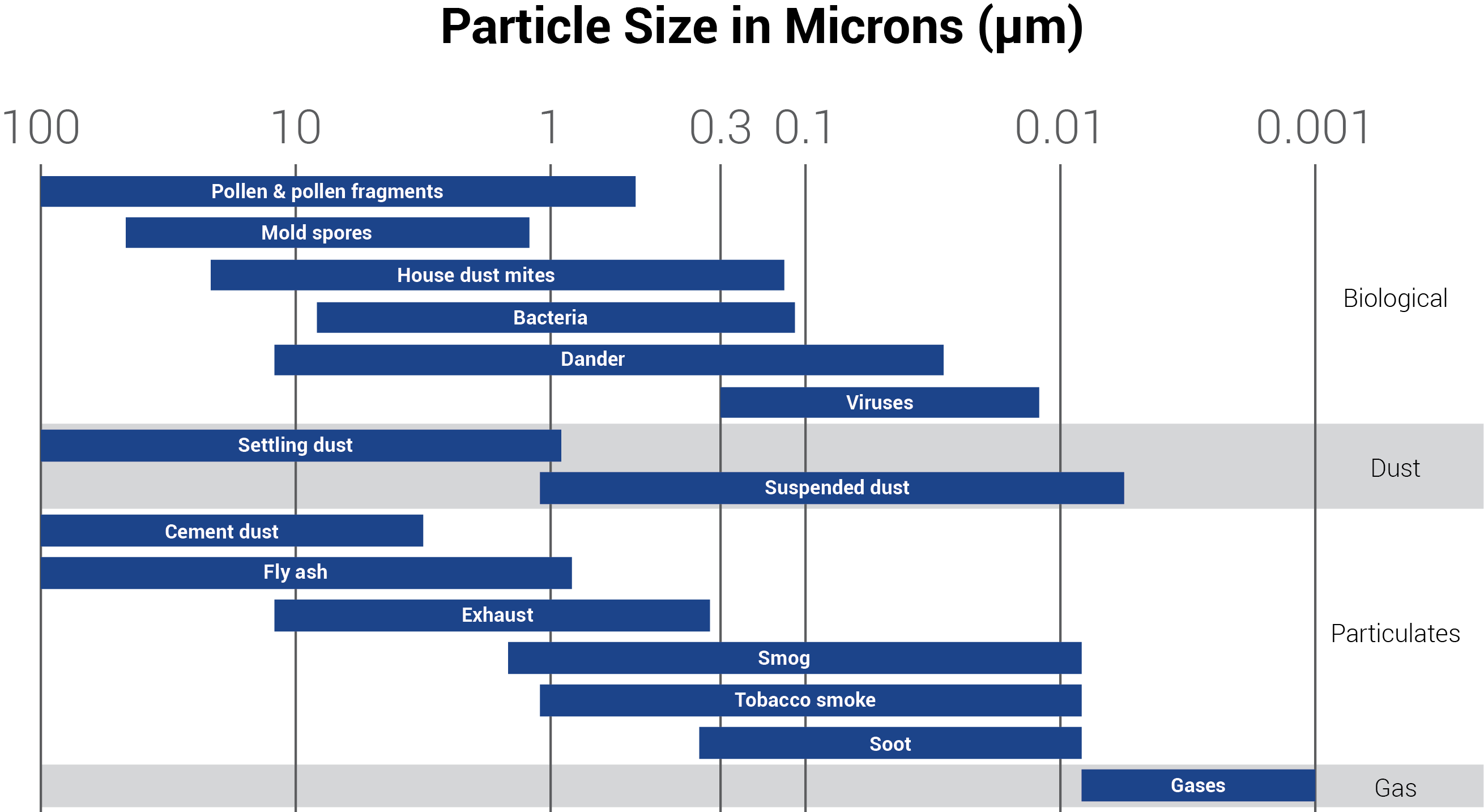

Cleanrooms are highly regulated environments that require the continuous monitoring of particle counts. In manufacturing cleanrooms, the safety and quality of products can be affected if too many particles enter the space. Setra’s CEMS provides a solution for environmental data, including particle counting, monitoring and recording needs required by various industries such as:

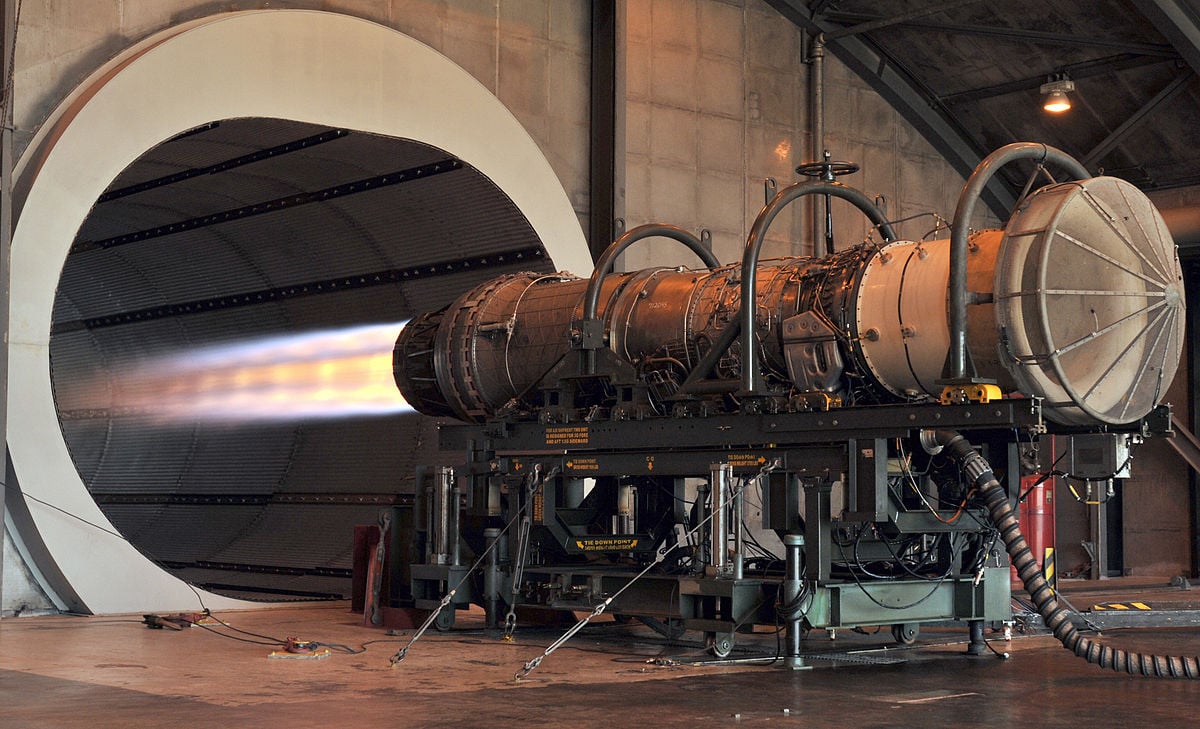

For referring to variable capacitive sensing technologies, four specific terms are commonly used: pressure transmitters, transducers, sensors, and switches. Capacitance is the detection and measurement of pressure by the change in voltage across a capacitor. The capacitance of sensing technology can be fixed or adjustable and varies dependent on the application. Capacitive sensing technology is highly precise, boasting accuracies of up to ± 0.07% of full scale. This pressure sensing technology is used for applications where a high degree of accuracy is crucial, such as engine test stands and pressure decay leak detection.

Demand based ventilation is an important aspect of HVAC design and control. Traditionally, demand based ventilation is done with CO2 sensors that look for a rise in CO2 and respond by increasing the air change rate to bring in more fresh air. To monitor and perform demand based ventilation, there is a control loop between the CO2 sensor and the HVAC control system. This type of ventilation is especially necessary for larger rooms where people gather, such as:

As dental offices prepare to reopen, they must consider new precautions to safely perform some procedures, especially those generating sprays of particles into the air. The most effective precaution is to create a negative pressure isolation room, or an airborne infection isolation room, in which to perform said procedures.

Thermal compensation is used to offset sensor performance when efficiency is impacted by fluctuations in temperature. Transducers used for precise testing and measurement applications, such as in engine test stands, undergo thermal compensation. Many transducers used in other critical applications may be thermally compensated. Thermally compensating sensors is crucial as temperature can have a significant impact on performance if not accounted for. This step in manufacturing counteracts the effects from changes in temperature that can influence the accuracy of a transducer's output. Thermal influence the accuracy of a transducer's output. Thermal compensation helps reduce the impact of temperature changes on sensitive components.

Negative pressure rooms are spaces engineered to control infections. In a hospital setting, they are referred to as isolation rooms, which must have both visual and audible alarming capabilities in the primary room pressure monitor. By utilizing negative pressure, these patient isolation spaces help prevent the spread of infectious airborne particles. COVID-19 has created heightened awareness of the need for negative pressure patient care spaces beyond the hospital isolation room. Examples include nursing homes, long-term care facilities, hospice care, and even dental offices.

Many companies in today's world are working to help support the urgent need for ventilator manufacturing. For this application, Setra's two smallest pressure sensors can function for OEMs, our Models 210 and 263.

On April 23, Setra hosted a webinar about our Room Pressure Monitors and how they help with isolation rooms and COVD-19 preparations. The recording of the webinar is below:

Cleanrooms are among the most strictly regulated critical environments, often continuously monitoring temperature, differential pressure, and relative humidity, in addition to the size and quantity of every particle. Continuous environmental monitoring helps ensure the quality of products manufactured in those clean spaces.

Subscribe to Our Blog!

Topics

- Critical Environments (182)

- HVAC/R (179)

- General Industrial (153)

- Building Automation (134)

- General Industrial OEM (92)

- Energy Management (85)

- Test and Measurement (66)

- HVAC/R OEM (58)

- Barometric (44)

- Alternative Fuels (42)

- Medical (40)

- Process/Mfg Tank Level (40)

- Water and Wastewater (39)

- OHV (38)

- Oil and Gas (35)

- Industrial Vacuum (29)

- Calibration (25)

- Semiconductor (25)

- Particle Counting (20)

- Cleanroom Monitoring (17)

- Room Pressure Monitoring (16)

- Trade Show (12)

- cleanroom environment (12)

- Scales (11)

- Environmental Monitoring (10)

- Power Monitoring (10)

- Healthcare (9)

- Power Meters (9)

- Software (9)

- cleanroom monitoring systems (9)

- Case Study (8)

- critical environment technologies (8)

- data centers (8)

- Humidity (7)

- particle counter (6)

- pressure transducers (6)

- LITE room pressure monitor (5)

- hardware and software cleanroom monitoring systems (5)

- setra lite (5)

- Compliance (3)

- Video (3)

- hospital spaces (3)

- FAQ & Troubleshooting (2)

- Monitoring Compounding Pharmacies (2)

- Semiconductor Manufacturing (2)

- agencies that monitor pharmacies (2)

- energy (2)

- hvac (2)

- laboratories (2)

- monitor compound pharmacy (2)

- protected environment (2)

- regulatory compliance (2)

- setra lite features (2)

- usp 797 (2)

- Current Sensors and Transducers (1)

- Current Transformers (1)

- Lithium-Ion Battery (1)

- Pressure (1)

- aerospace cleanrooms (1)

- cems (1)

- digital transformation (1)

- ipv6 multicast (1)

- ipv6 multicast address (1)

- ipv6 multicast address range (1)

- isolation room pressure monitoring (1)

- multicast address ipv6 (1)

- multicast ipv6 (1)

- operating room (1)

- pharma 4.0 (1)

- pressure sensor (1)

- pressure transducer companies (1)

- semi conductor (1)

- sensors and transducers (1)

- setra pressure transducers (1)

- submetering (1)

- sustainability (1)

- temperature monitor (1)

- temperature monitoring for pharmacies (1)

- transducers (1)

- usp 800 (1)

- water (1)

- what does hvac stand for (1)

- what is a transducer (1)

- what is hvac (1)