As of July 22, the RoHS exemption for industrial monitoring and control instruments will end. Non- compliant product cannot be CE marked and sold in the European Union or to customers who otherwise require the CE mark.

Setra Blog

The Internet of Things (IoT) is changing the way people run their homes. More and more devices are becoming available to consumers that allow them to automate their thermostats and regulate their power consumption, often-times controlling these systems from the phone in their pocket. Products like the Nest thermostat and the Sense home energy monitor provide homeowners convenient tools that also help save utility costs.

Building Automation

In commercial and industrial buildings, there are similar (albeit far more robust) systems and protocols used for the same purposes called building automation. Building automation is the automatic and centralized control of a building’s heating, ventilation, air conditioning, security, electrical, and other systems through a Building Automation System (BAS).

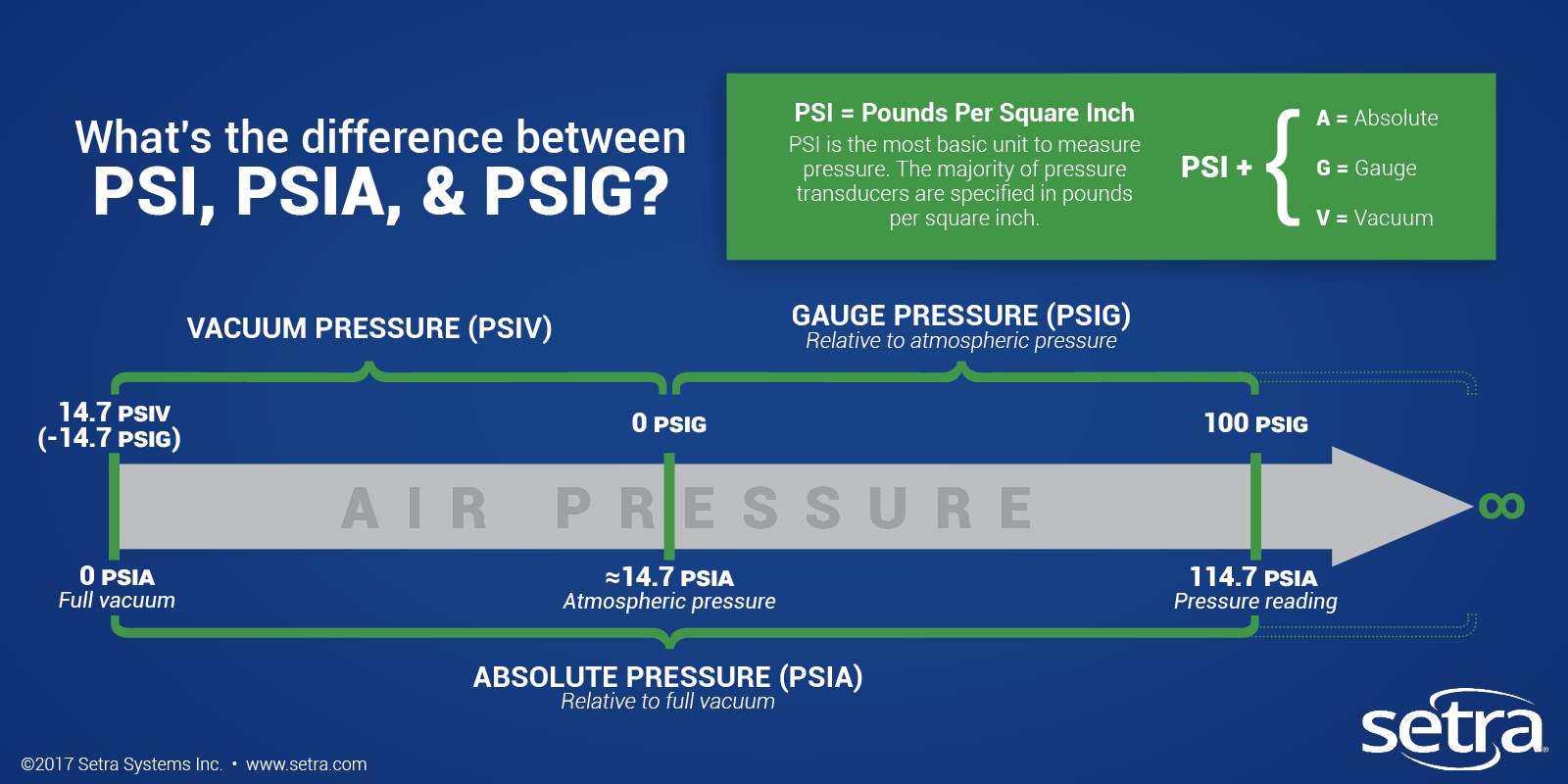

Absolute pressure is the pressure measured relative to a perfect vacuum, which is considered absolute zero pressure. This means it includes the atmospheric pressure in addition to the pressure of the system being measured.

An incredibly diverse array of applications require the measurement of air pressure. Depending on the application, users need to be able to interpret pressure readings in different ways and use appropriate units to reflect those readings accurately.

Absolute Pressure Defined

Absolute pressure is measured relative to a full vacuum. In contrast, the pressure that is measured against atmospheric pressure (also known as barometric pressure) is called gauge pressure. A full vacuum has an absolute pressure reading of 0 PSIA and the average barometric pressure at sea level is ~14.7 PSIA.

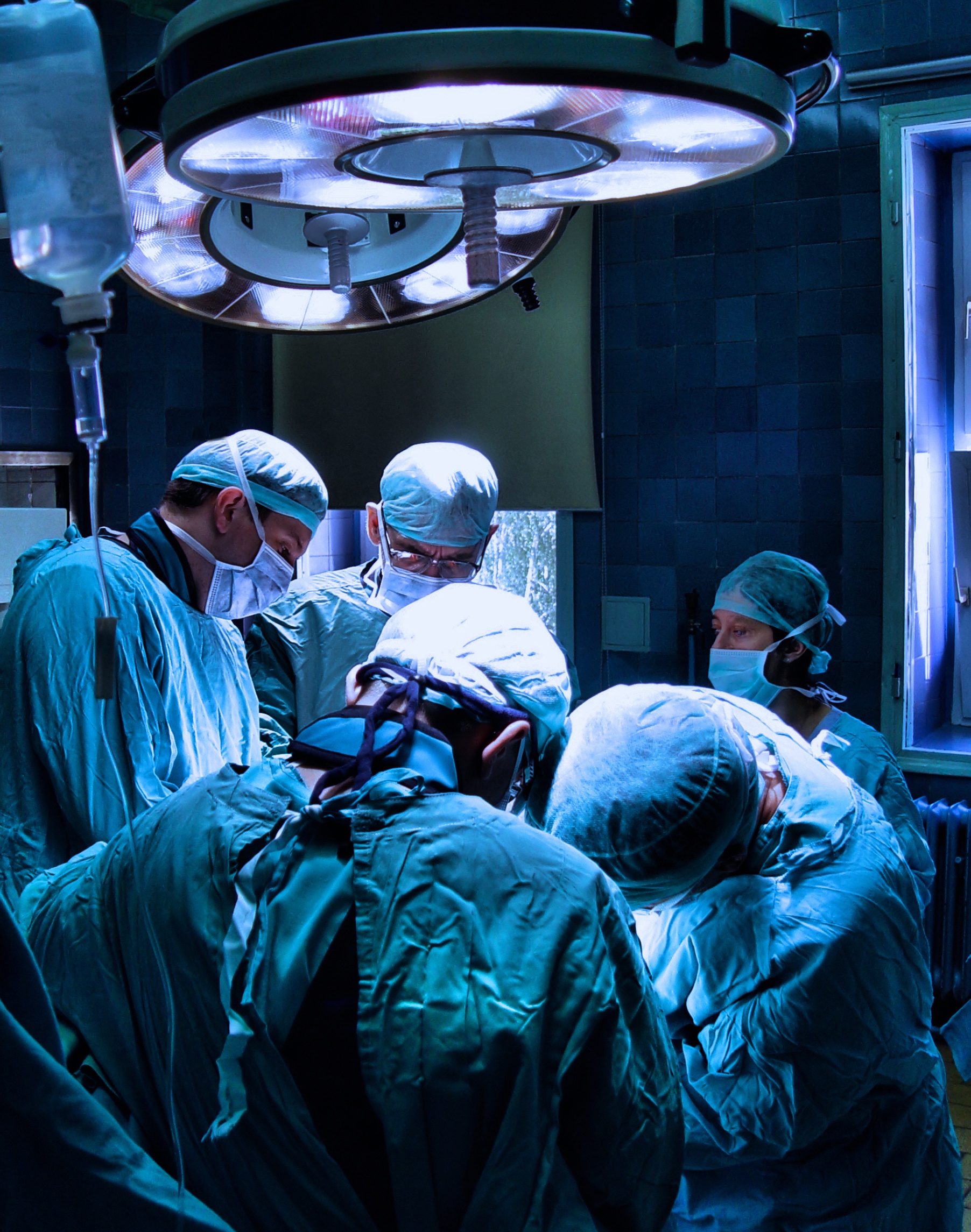

Ensuring the accuracy of transducers used in the measurement of room pressure in critical environments is extremely important in order to maintain patient safety. Because the differences in measured pressure are so small (only fractions of an inch of water column) calibrating these devices can be very tedious and usually difficult to perform without the right tools and processes.

In general, there are two industry standard methods of low pressure calibration: hand pump calibration and automated calibration.

The Joint Commission (TJC) is a non-profit organization that evaluates and accredits healthcare organizations in the United States, ensuring that hospitals and other medical facilities are providing safe and high-quality care to their patients. Inspections occur every three years and take between 2 to 3 days. In most jurisdictions, Medicare and Medicaid funding is contingent on accreditation by TJC.

One of the most important standards scored in a Joint Commission evaluation is room pressurization (EC.02.05.01). According to ASHRAE Standard 170 (used specifically by TJC as its standard), over 60 different areas of concern within a facility need to be either positively or negatively pressured. Pressurization in these spaces is tested simply by holding a tissue at the bottom of a door and determining whether the tissue is blown back away or sucked towards the gap.

Did you know that companies spend hundreds of millions of dollars on research and development for off-highway vehicle engines? A portion of the R&D goes into developing specialized engine test stands to ensure that the engines are functioning properly.

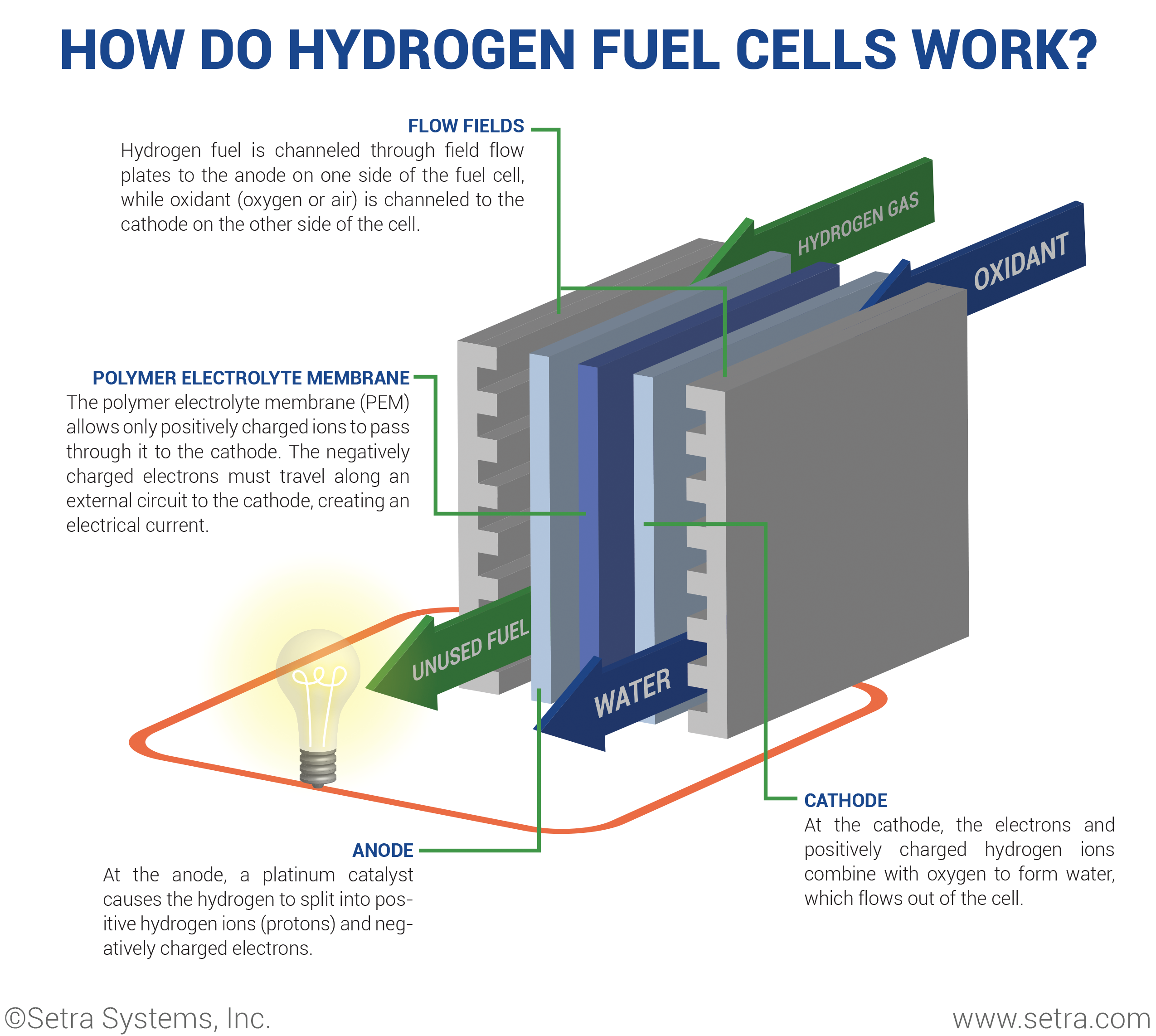

Engine test stands are complex, engineered systems designed to measure, control and record parameters during the different engine manufacturing stages.Although hydrogen is in its infancy as a fuel source, its future is incredibly bright. The technology behind hydrogen fuel cells is improving daily and its viability as a replacement to the internal combustion engine seems likely. Hydrogen is already being used in specialty vehicles such as forklifts and buses, and it’s only a matter of time before infrastructure is in place to serve the consumer automotive market. Why do hydrogen fuel cells have such great appeal? Because their only byproducts are heat and water vapor, making hydrogen fuel cells a truly zero-emission locomotive technology.

In manufacturing, there are two standards used to measure the different grades of electrical enclosures and how resistant they are to the ingress of certain materials. NEMA ratings and IP ratings both define degrees of protection against substances such as water and dust, but use different test methods and parameters to define their enclosure types (NEMA 250 and IEC standard 60529).

Capacitance is the ability of an object to hold an electrical charge. Capacitors are components in an electrical circuit that can store a charge and are considered one of the three fundamental electronic components along with inductors and resistors.

Simply put, barometric pressure is the measurement of air pressure in the atmosphere, specifically the measurement of the weight exerted by air molecules at a given point on Earth. Barometric pressure changes constantly and is always different depending on where the reading takes place.

Subscribe to Our Blog!

Topics

- Critical Environments (182)

- HVAC/R (179)

- General Industrial (153)

- Building Automation (134)

- General Industrial OEM (92)

- Energy Management (85)

- Test and Measurement (66)

- HVAC/R OEM (58)

- Barometric (44)

- Alternative Fuels (42)

- Medical (40)

- Process/Mfg Tank Level (40)

- Water and Wastewater (39)

- OHV (38)

- Oil and Gas (35)

- Industrial Vacuum (29)

- Calibration (25)

- Semiconductor (25)

- Particle Counting (18)

- Cleanroom Monitoring (17)

- Room Pressure Monitoring (16)

- Trade Show (12)

- cleanroom environment (12)

- Scales (11)

- Environmental Monitoring (10)

- Power Monitoring (10)

- Healthcare (9)

- Power Meters (9)

- Software (9)

- cleanroom monitoring systems (9)

- Case Study (8)

- critical environment technologies (8)

- Humidity (7)

- data centers (7)

- particle counter (6)

- pressure transducers (6)

- LITE room pressure monitor (5)

- hardware and software cleanroom monitoring systems (5)

- setra lite (5)

- Compliance (3)

- Video (3)

- hospital spaces (3)

- FAQ & Troubleshooting (2)

- Monitoring Compounding Pharmacies (2)

- Semiconductor Manufacturing (2)

- agencies that monitor pharmacies (2)

- energy (2)

- hvac (2)

- laboratories (2)

- monitor compound pharmacy (2)

- protected environment (2)

- regulatory compliance (2)

- setra lite features (2)

- usp 797 (2)

- Current Sensors and Transducers (1)

- Current Transformers (1)

- Pressure (1)

- aerospace cleanrooms (1)

- cems (1)

- digital transformation (1)

- ipv6 multicast (1)

- ipv6 multicast address (1)

- ipv6 multicast address range (1)

- isolation room pressure monitoring (1)

- multicast address ipv6 (1)

- multicast ipv6 (1)

- operating room (1)

- pharma 4.0 (1)

- pressure sensor (1)

- pressure transducer companies (1)

- semi conductor (1)

- sensors and transducers (1)

- setra pressure transducers (1)

- submetering (1)

- sustainability (1)

- temperature monitor (1)

- temperature monitoring for pharmacies (1)

- transducers (1)

- usp 800 (1)

- water (1)

- what does hvac stand for (1)

- what is a transducer (1)

- what is hvac (1)