Looking at your electric bill can be a daunting task. There are many factors that can affect your bill’s total — factors that are only amplified in large commercial and industrial sites.

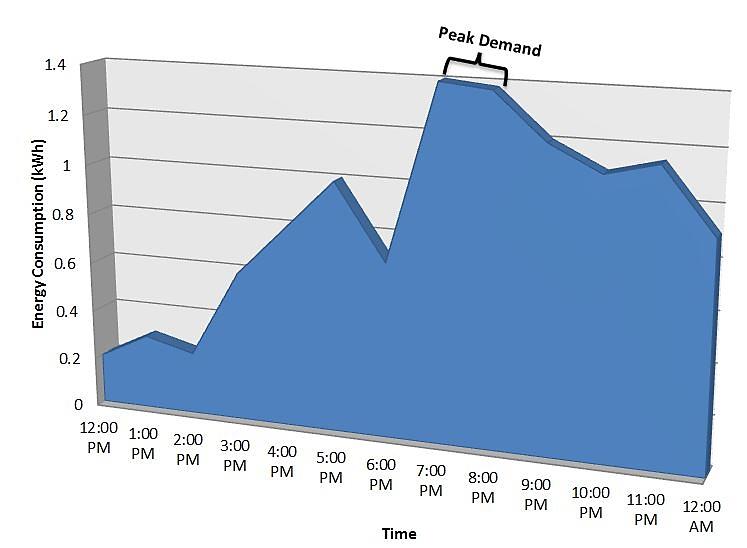

One such consideration is peak demand. Peak demand is the largest instance of power usage in a given time frame, typically a rolling fifteen minute window. Measured in kilowatts (kW), peak demand is different than consumption. Total consumption is measured in kilowatt hours (kWh) over a given period of time (e.g. monthly, quarterly, etc.).