While it is important to maintain proper relative humidity levels in office buildings for worker comfort and productivity, it is also just as important to maintain proper levels in factories, production facilities and art galleries to protect industrial, commercial and artistic products.

Setra Blog

Recently, the Department of Energy (DOE) released a new requirement that goes into effect on Jan. 1st, 2017 as part of the "Energy Conservation Program: Test Procedures for Central Conditioners & Heat Pumps.” All manufacturers of heating and cooling systems need to ensure that the AHR units they manufacture for residential and small commercial applications meet this new standard.

One of the biggest concerns after pressure transducers have been installed is knowing how accurate the results will be over time. As a result pressure transducers are replaced more often than necessary or are calibrated with outdated technology. Low-pressure transducers used in critical applications require calibration after extended use to ensure

Hydrogen is the most plentiful element in the universe and is now becoming a viable fuel source for many applications. Due to its efficiency and low environmental impact, the interest in hydrogen being the "fuel of the future" continues to grow. The many features and benefits to hydrogen make it an ideal choice for many up-and-coming industrial applications. A few of the more common applications are:

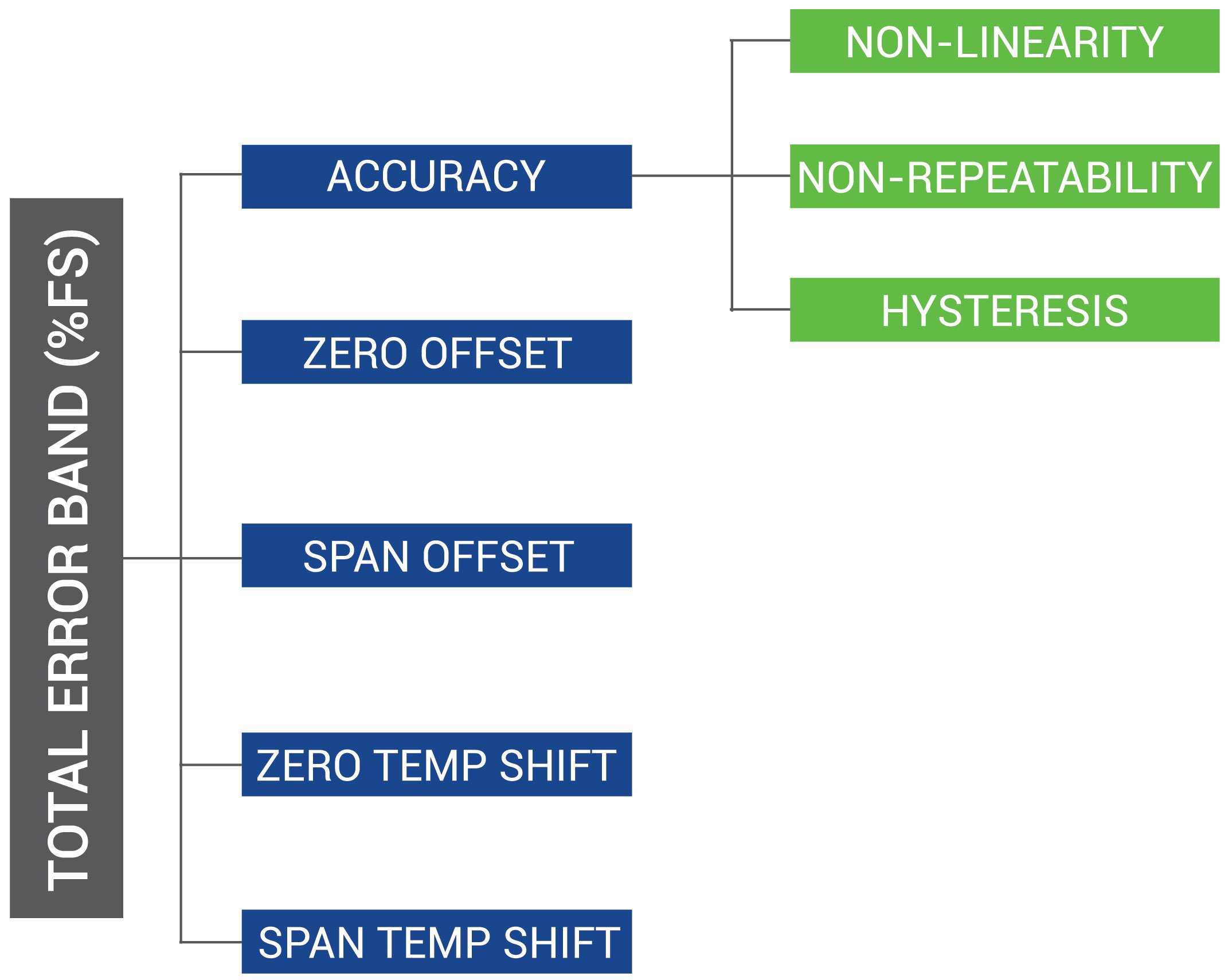

Total Error Band (TEB) is a measurement of worst case error; it is the most comprehensive and concise measurement of a sensors true accuracy over a compensated temperature range. TEB is extremely important to know when trying to determine how well a sensor will work within a particular design system. By calculating TEB you'll be able to understand the different possibilities for error. Formulating TEB can be tricky if you don't have the right inputs readily available.

Happy Halloween From Setra

Have you ever wanted to build your own Haunted House or Spooky Trail?

I'm sure we've all thought about it one time or another. You know what I'm talking about. Places like amusement parks, fairs, or even a homemade one that your “Halloween Crazed” neighbors down the street built themselves. But how do they work?

Proof pressure and burst pressure are critical specifications for pressure sensors and other pressure-related devices, but they serve different purposes.

Typically, there are many different pressure specifications indicated on a pressure transducer data sheet. Interestingly enough, two of the most important pressure specifications are often easily overlooked; proof and burst pressure. Selecting a pressure transducer without noticing these pressure ranges is one of the top reasons for transducer failure. Both pressure specifications are considered to act as an upper limit for the device’s operating range. So, what exactly is the difference between proof and burst pressure?

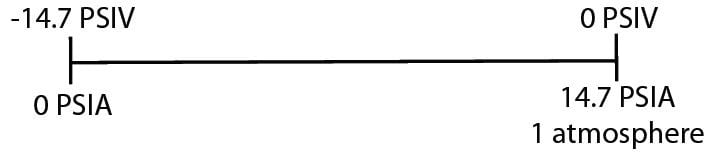

Absolute pressure is measured relative to a full vacuum (0 PSIA = 14.7 PSIV). The electrical output of an absolute pressure transducer is 0 VDC at 0 PSIA and full scale output (typically 5 VDC) at full scale pressure (in PSIA). PSIA (pounds per square inch absolute) is a unit of pressure measured relative to a full vacuum. A vacuum can refer to any pressure between 0 PSIA and 14.7 PSIA.

Low pressure measurements are required in various applications such as air flow, static duct and cleanroom pressures in HVAC and energy management systems (EMS). Other applications include use in medical instrumentation, environmental pollution control, boil combustion efficiency and a wide variety of research and development requirements. Although the focus will center mainly on air flow and pressure, the same principles

There are several techniques for managing safe and reliable pressurized rooms in healthcare and laboratory applications. When anterooms are present, such as those used for isolation rooms and pharmacies, it is not always clear how the anteroom should be pressurized in relation to the adjoining room and hallway.

Subscribe to Our Blog!

Topics

- Critical Environments (182)

- HVAC/R (179)

- General Industrial (153)

- Building Automation (134)

- General Industrial OEM (92)

- Energy Management (85)

- Test and Measurement (66)

- HVAC/R OEM (58)

- Barometric (44)

- Alternative Fuels (42)

- Medical (40)

- Process/Mfg Tank Level (40)

- Water and Wastewater (39)

- OHV (38)

- Oil and Gas (35)

- Industrial Vacuum (29)

- Calibration (25)

- Semiconductor (25)

- Particle Counting (20)

- Cleanroom Monitoring (17)

- Room Pressure Monitoring (16)

- Trade Show (12)

- cleanroom environment (12)

- Scales (11)

- Environmental Monitoring (10)

- Power Monitoring (10)

- Healthcare (9)

- Power Meters (9)

- Software (9)

- cleanroom monitoring systems (9)

- Case Study (8)

- critical environment technologies (8)

- data centers (8)

- Humidity (7)

- particle counter (6)

- pressure transducers (6)

- LITE room pressure monitor (5)

- hardware and software cleanroom monitoring systems (5)

- setra lite (5)

- Compliance (3)

- Video (3)

- hospital spaces (3)

- FAQ & Troubleshooting (2)

- Monitoring Compounding Pharmacies (2)

- Semiconductor Manufacturing (2)

- agencies that monitor pharmacies (2)

- energy (2)

- hvac (2)

- laboratories (2)

- monitor compound pharmacy (2)

- protected environment (2)

- regulatory compliance (2)

- setra lite features (2)

- usp 797 (2)

- Current Sensors and Transducers (1)

- Current Transformers (1)

- Lithium-Ion Battery (1)

- Pressure (1)

- aerospace cleanrooms (1)

- cems (1)

- digital transformation (1)

- ipv6 multicast (1)

- ipv6 multicast address (1)

- ipv6 multicast address range (1)

- isolation room pressure monitoring (1)

- multicast address ipv6 (1)

- multicast ipv6 (1)

- operating room (1)

- pharma 4.0 (1)

- pressure sensor (1)

- pressure transducer companies (1)

- semi conductor (1)

- sensors and transducers (1)

- setra pressure transducers (1)

- submetering (1)

- sustainability (1)

- temperature monitor (1)

- temperature monitoring for pharmacies (1)

- transducers (1)

- usp 800 (1)

- water (1)

- what does hvac stand for (1)

- what is a transducer (1)

- what is hvac (1)