When selecting an absolute, gauge or differential pressure sensor, the lines between absolute and gauge can be blurred. There are many differences between the two regarding performance and application. Therefore, it is essential to determine whether you need a gauge or absolute reference for measuring pressure. Like selecting a pressure range, it is important to select the correct pressure measurement to avoid errors in your measurement, especially when requiring a low range device.

Setra Blog

June 27, 2016

What is the difference between an absolute sensor and a gauge sensor and when should I use each?

IP Ratings are used to define levels of sealing effectiveness and degrees of protection against substances in electrical enclosures. Ratings are defined by the international standard EN 60529 (British BS EN 60529:1992, European IEC 60509:1989).

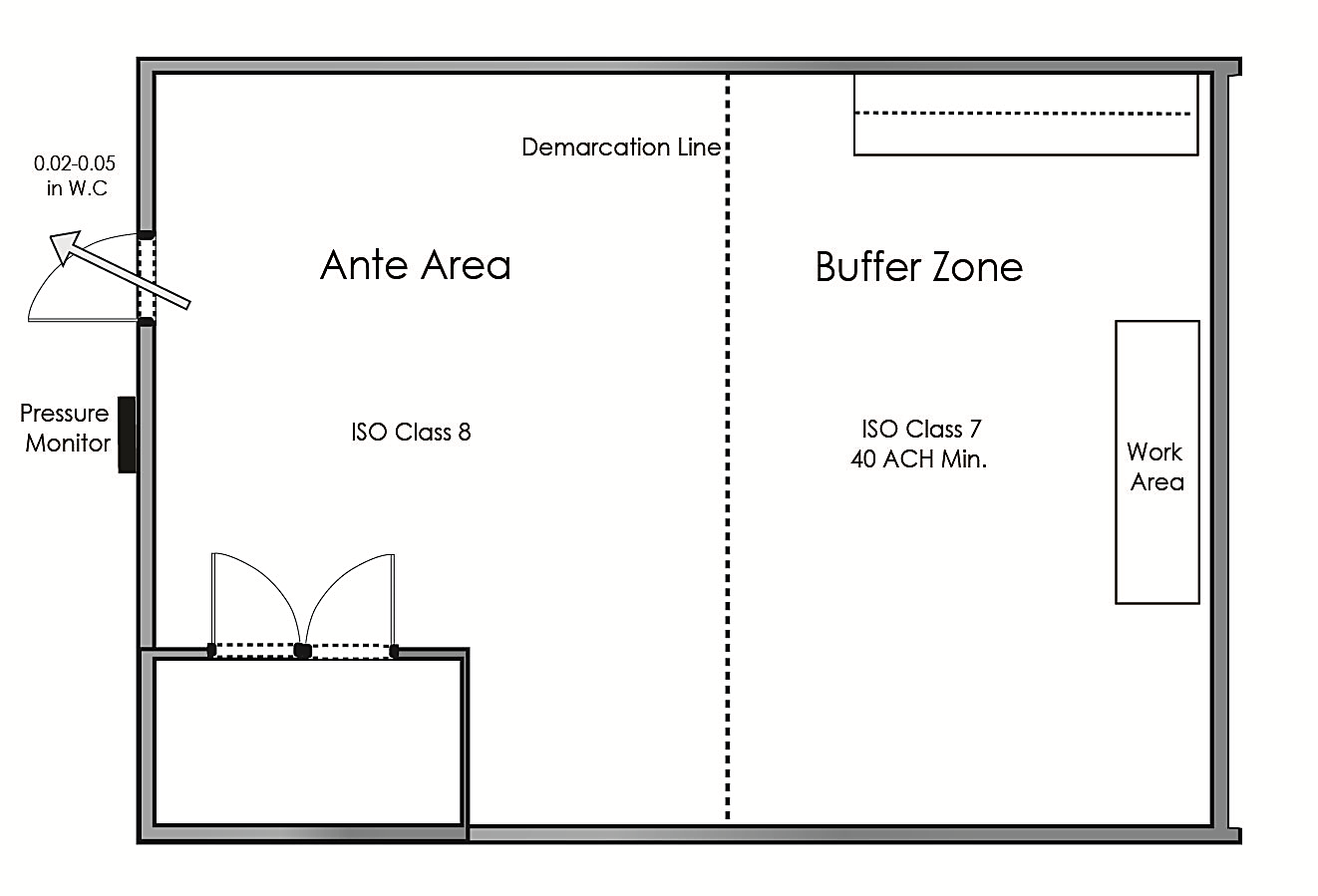

Engineering proper HVAC systems for critical environments often involves distinct areas of room pressure control and directional airflow. An anteroom between a primary room and corridor ensures a safe airflow buffer zone between the controlled pressurized space and an unclean area. The two spaces are separated by a completely walled area with a door. However, in some applications an ante area without walls or a door can achieve the same effect.

Buildings Can Get Sick Too…

When you are not feeling well, you usually attribute the root cause to bacteria or an infectious person. Not many people realize the root cause of an illness can be improperly regulated HVAC systems in buildings. Indoor air quality is becoming a matter of concern. In fact, Americans on average spend 90% of their time indoors; less than an hour a day is spent outside. All of this time spent indoors in a poorly controlled environment can lead to sick building syndrome (SBS).

Although there are a variety of methods for leak detection, the most common is pressure decay. Other methods can be time consuming and costly, whereas pressure decay leak detection is a simple test that's sensitive to very small leaks. This method is ideal for high-volume industries that require quick accurate tests within their facility. By pressurizing the unit under test (UUT) and then removing it from the pressure source, any detection of pressure loss is a result of a leak within the UUT. Before performing a pressure decay leak detection test, make sure your system is properly setup. After the system is setup, follow the below steps to test the UUT with a differential pressure transducer.

The consequences of an unplanned leak in an air compressor may be higher than you think. Air leakage can occur in any part of an air system, at any given time. Many users are blindsided by this issue. Air leaks are a significant source of wasted energy, often wasting 20-30% of a compressor’s output. Did you know that unmaintained plants waste at least 20% of air production capacity? In addition to wasting energy, undetected leaks can contribute to financial and operational losses.

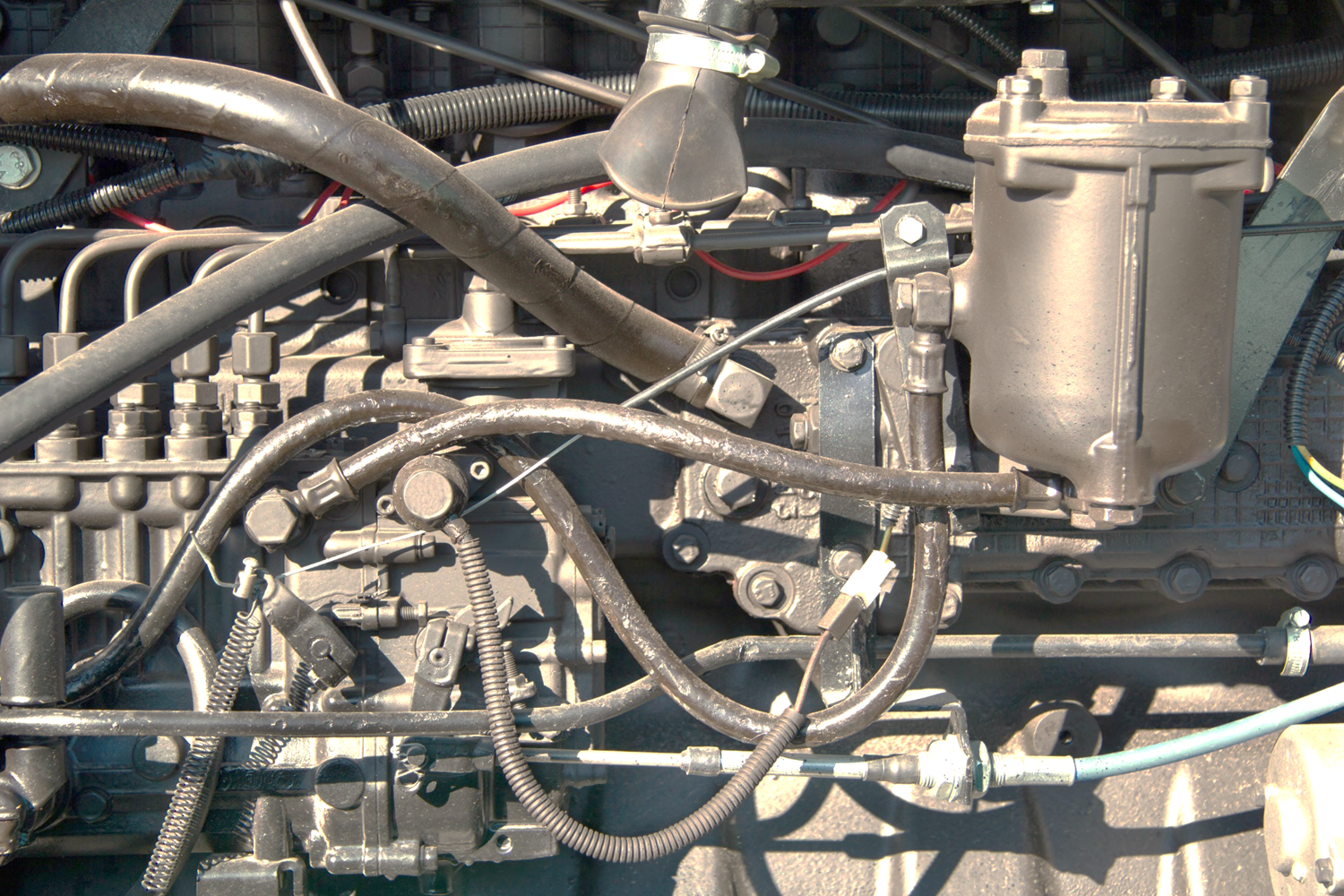

In the test and measurement industry, manufacturers need to test the products they build. Pressure sensors are needed in test stands to measure pressure across various mediums, including air, fuel, coolant, gas. Testing can be expensive and having a reliable sensor eliminates costly downtime.

Although mold has many medical uses, it can be a huge problem for homes and buildings, especially if mold growth goes undetected. Mold spores spread easily and can grow anywhere, including carpet, clothing, food, paper as well as drywall, areas inside walls, around leaking or condensing pipes, and above ceiling tiles. Since mold cannot be completely eradicated and can be costly to fix, the best approach is to prevent mold before it becomes a problem. So how do you prevent mold growth?

Protective Environment (PE) rooms are hospital rooms designed to protect a high-risk immunocompromised patient from human and environmental airborne pathogens. These are positive pressure rooms intended to keep patients safe during recovery from cancer treatment or stem-cell transplant.

Airborne Infection Isolation (AII) rooms, commonly called negative pressure rooms, are single-occupancy patient care spaces designed to isolate airborne pathogens to a safe containment area. AII rooms are a specialized application of a hospital’s HVAC system, where the airflow supplied into the room is balanced with exhaust airflow to create at least -0.01” WC negative differential pressure with respect to an adjacent space, usually the hallway or an anteroom. In simple terms, this provides a gentle flow of air under a closed doorway and into the room so that no airborne particulates escape into nursing staff or public areas. Exhaust from these rooms is not recirculated in the HVAC system. Instead, exhaust air typically moves in dedicated ductwork to ventilation stacks on the rooftop, where atmospheric air provides sufficient dilution to make the resulting air safe.

Subscribe to Our Blog!

Topics

- Critical Environments (182)

- HVAC/R (179)

- General Industrial (153)

- Building Automation (134)

- General Industrial OEM (92)

- Energy Management (85)

- Test and Measurement (66)

- HVAC/R OEM (58)

- Barometric (44)

- Alternative Fuels (42)

- Medical (40)

- Process/Mfg Tank Level (40)

- Water and Wastewater (39)

- OHV (38)

- Oil and Gas (35)

- Industrial Vacuum (29)

- Calibration (25)

- Semiconductor (25)

- Particle Counting (18)

- Cleanroom Monitoring (17)

- Room Pressure Monitoring (16)

- Trade Show (12)

- cleanroom environment (12)

- Scales (11)

- Environmental Monitoring (10)

- Power Monitoring (10)

- Healthcare (9)

- Power Meters (9)

- Software (9)

- cleanroom monitoring systems (9)

- Case Study (8)

- critical environment technologies (8)

- Humidity (7)

- data centers (7)

- particle counter (6)

- pressure transducers (6)

- LITE room pressure monitor (5)

- hardware and software cleanroom monitoring systems (5)

- setra lite (5)

- Compliance (3)

- Video (3)

- hospital spaces (3)

- FAQ & Troubleshooting (2)

- Monitoring Compounding Pharmacies (2)

- Semiconductor Manufacturing (2)

- agencies that monitor pharmacies (2)

- energy (2)

- hvac (2)

- laboratories (2)

- monitor compound pharmacy (2)

- protected environment (2)

- regulatory compliance (2)

- setra lite features (2)

- usp 797 (2)

- Current Sensors and Transducers (1)

- Current Transformers (1)

- Pressure (1)

- aerospace cleanrooms (1)

- cems (1)

- digital transformation (1)

- ipv6 multicast (1)

- ipv6 multicast address (1)

- ipv6 multicast address range (1)

- isolation room pressure monitoring (1)

- multicast address ipv6 (1)

- multicast ipv6 (1)

- operating room (1)

- pharma 4.0 (1)

- pressure sensor (1)

- pressure transducer companies (1)

- semi conductor (1)

- sensors and transducers (1)

- setra pressure transducers (1)

- submetering (1)

- sustainability (1)

- temperature monitor (1)

- temperature monitoring for pharmacies (1)

- transducers (1)

- usp 800 (1)

- water (1)

- what does hvac stand for (1)

- what is a transducer (1)

- what is hvac (1)