The sensing and measurement of physical quantities through small changes in electrical capacitance is scarcely a new concept. The natural benefits of this approach were recognized for many years. But it was not until Setra engineers introduced new materials, new designs, and innovative, dedicated circuitry that the techniques full potential was realized in the practical, real world of pressure measurement.

Setra Blog

HVAC controls are built around a number of parameters that affect a building’s interior environment; temperature, humidity, air intake, and air exhaust. Reliable inputs are critical to effective control. Setra provides robust, accurate sensors to help you control your air handling equipment with ease, efficiency, and dependability.

Here at Setra we realize that each customer is unique and every application has different requirements that necessitate different features in a pressure sensor. We have the best interests of the customer in mind and realize we may not have the best sensor for a particular situation.

COMING SOON

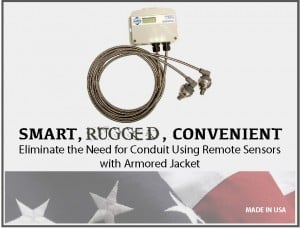

231RS Wet-to-Wet, Differential, Multi-Configurable Pressure Transducer with Armored Jacket

The Model 231RS wet-to-wet differential pressure transducer with remote sensors reduces labor, materials, and time. The differential pressure sensors are installed directly into the pipe and electrical connection is made between the remote sensors and the Model 231RS via cables or conduit, reducing labor cost by one-third and the cost of copper to connect the pressure transducer to the pipe.

NOW AVAILABLE

Setra Model 3550 - Compact Low Pressure OEM Pressure Transducers

The 3550 is perfect for OEMs that need consistent high levels of performance, reliability and stability because of the units small package size with all 316L stainless steel wetted parts at an unbeatable price performance ratio. A wide choice of electrical outputs as well as both electrical and pressure connections means the unit is suitable for most applications without modifications.

Selecting a low-differential pressure transducer for critical-care ventilation is one of the most important decisions mechanical designers, engineers and architects can make. These transducers perform precise monitoring and contamination control of isolation-room pressures in critical environments. Properly selected and installed, they help prevent the spread of communicable diseases like tuberculosis (TB).

Setra Systems and DENT Instruments Announce Joint Development Partnership

"The Joint Development is part of Setra’s strategy to expand their energy management solutions offering to their current customer base. The project will leverage the technical, engineering and commercial expertise of the two companies to identify opportunities to innovate and provide solutions for the industry’s greatest challenges.

There are many risks associated with unmonitored humidity levels in buildings. The most significant of which is the health risks posed to the building’s occupants. Sick Building Syndrome can severely affect occupants’ comfort and productivity, but more alarming are some of the respiratory and other health ailments which can arise from unmonitored humidity levels.

Shock & vibration are two potential mechanical problems for pressure transducers.

Shock is a sudden, unexpected impact that transmits energy to a device in a relatively short time interval. For a pressure transducer, that energy passes through the stainless steel up through the housing. Shock may originate from rough transportation and handling, such as by trucks, forklifts and conveyors. Alternately, shock can be caused simply by dropping the transducer on the shop floor or by an assembler slamming a cabinet door adjacent to it. A transducer may not be damaged by a single shock, but can experience fatigue failure with numerous low-level shocks over the course of its life.

Subscribe to Our Blog!

Topics

- Critical Environments (182)

- HVAC/R (179)

- General Industrial (153)

- Building Automation (134)

- General Industrial OEM (92)

- Energy Management (85)

- Test and Measurement (66)

- HVAC/R OEM (58)

- Barometric (44)

- Alternative Fuels (42)

- Medical (40)

- Process/Mfg Tank Level (40)

- Water and Wastewater (39)

- OHV (38)

- Oil and Gas (35)

- Industrial Vacuum (29)

- Calibration (25)

- Semiconductor (25)

- Particle Counting (18)

- Cleanroom Monitoring (17)

- Room Pressure Monitoring (16)

- Trade Show (12)

- cleanroom environment (12)

- Scales (11)

- Environmental Monitoring (10)

- Power Monitoring (10)

- Healthcare (9)

- Power Meters (9)

- Software (9)

- cleanroom monitoring systems (9)

- Case Study (8)

- critical environment technologies (8)

- Humidity (7)

- data centers (7)

- particle counter (6)

- pressure transducers (6)

- LITE room pressure monitor (5)

- hardware and software cleanroom monitoring systems (5)

- setra lite (5)

- Compliance (3)

- Video (3)

- hospital spaces (3)

- FAQ & Troubleshooting (2)

- Monitoring Compounding Pharmacies (2)

- Semiconductor Manufacturing (2)

- agencies that monitor pharmacies (2)

- energy (2)

- hvac (2)

- laboratories (2)

- monitor compound pharmacy (2)

- protected environment (2)

- regulatory compliance (2)

- setra lite features (2)

- usp 797 (2)

- Current Sensors and Transducers (1)

- Current Transformers (1)

- Pressure (1)

- aerospace cleanrooms (1)

- cems (1)

- digital transformation (1)

- ipv6 multicast (1)

- ipv6 multicast address (1)

- ipv6 multicast address range (1)

- isolation room pressure monitoring (1)

- multicast address ipv6 (1)

- multicast ipv6 (1)

- operating room (1)

- pharma 4.0 (1)

- pressure sensor (1)

- pressure transducer companies (1)

- semi conductor (1)

- sensors and transducers (1)

- setra pressure transducers (1)

- submetering (1)

- sustainability (1)

- temperature monitor (1)

- temperature monitoring for pharmacies (1)

- transducers (1)

- usp 800 (1)

- water (1)

- what does hvac stand for (1)

- what is a transducer (1)

- what is hvac (1)