It is commonly known that gowning procedures and air flow requirements are essential to maintaining a sterile clean room environment. Workers and operators don’t realize how crucial employee training is and the enormous impact employees have with the sanitation of the cleanroom. Unfortunately, humans are considered to be the biggest threat to the cleanroom and the largest source for contaminants, accounting for 75% to 80% of particles and microbes generated in a room. Understanding how personnel create particles and microbes or bring in contaminants, can help structure proper employee training, greatly bringing down the risk for clean environment contamination.

Setra Blog

Thank you to all who visited us at Booth C1452 in the Building Automation and Controls section of the AHR Expo this year in Las Vegas, Nevada! We enjoyed seeing both new and familar faces! The world's largest HVACR event was anything but boring and we think the 60,000 attendees would have to agree.

January 05, 2017

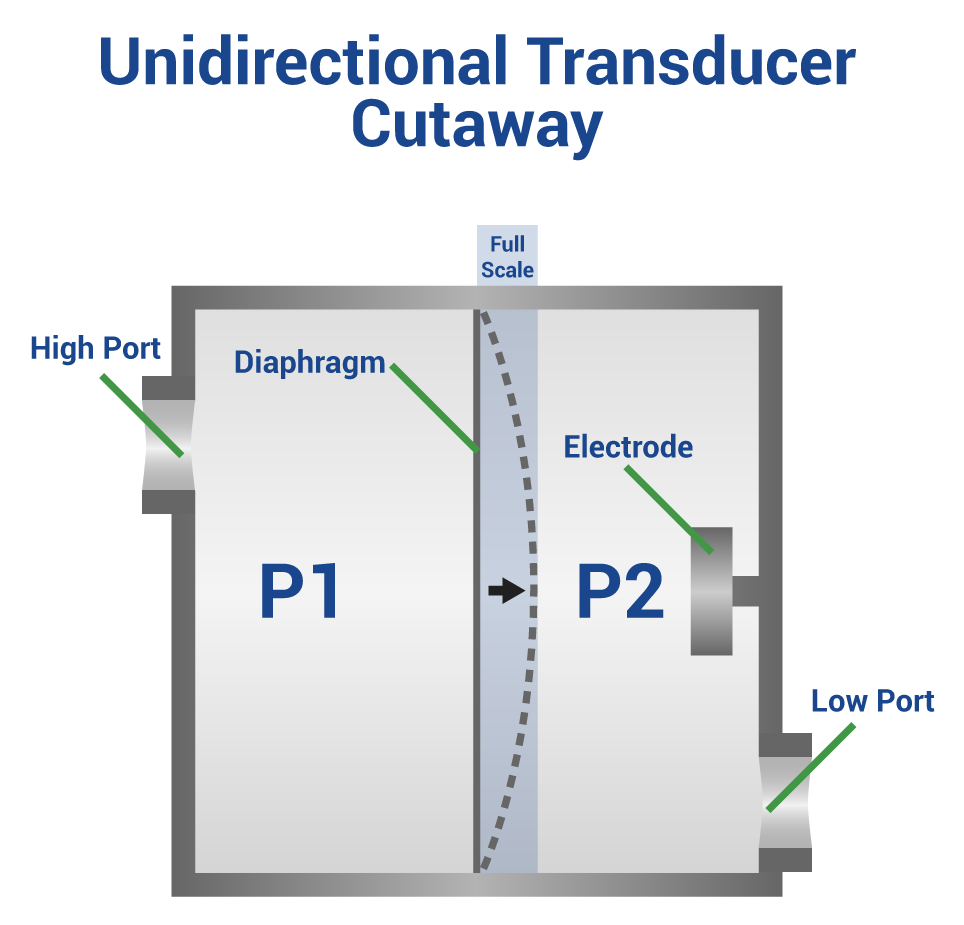

What is the Difference Between Unidirectional and Bidirectional Pressure Transducers?

Unidirectional Pressure Transducers

Unidirectional pressure transducers measure between zero and a positive pressure. The diaphragm of the sensor should only move in one direction and will produce a positive voltage or milliamp output.

Pressure transducers today are more rugged and reliable than ever. Made of stainless steel construction, they provide abundant overpressure protection, improved total error band, and offer negligible orientation and vibration effects. They are ideal for long-term use even in harsh environments of extreme temperature, humidity, and vibration.

Monitoring and controlling room pressure in laboratory and healthcare settings can do more than just ensure directional airflow (positive or negative pressure rooms). Proper room pressure also contributes to saving energy. Overpressure or under-pressure scenarios mean that airflow, or even temperature control, are not optimal.

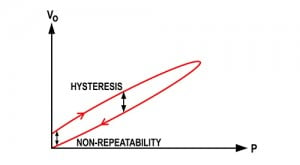

The accuracy of differential pressure transducers has greatly improved to provide better solutions for demanding applications. This article discusses why accuracy is an important consideration when selecting a pressure transducer for low-differential, critical pressure applications.

Operating Rooms consume a great deal of energy, considering the high airflow requirements needed, bright lighting, and significant plug load from patient care equipment. There are, however, strategies to conserve energy and still meet the stringent safety requirements of maintaining positive room pressure. Two conditions need to be met to enable OR energy savings. The first is a method to trigger occupied and unoccupied states. And the second is to act on that state change to setback both temperature and airflow.

While it is important to maintain proper relative humidity levels in office buildings for worker comfort and productivity, it is also just as important to maintain proper levels in factories, production facilities and art galleries to protect industrial, commercial and artistic products.

Recently, the Department of Energy (DOE) released a new requirement that goes into effect on Jan. 1st, 2017 as part of the "Energy Conservation Program: Test Procedures for Central Conditioners & Heat Pumps.” All manufacturers of heating and cooling systems need to ensure that the AHR units they manufacture for residential and small commercial applications meet this new standard.

One of the biggest concerns after pressure transducers have been installed is knowing how accurate the results will be over time. As a result pressure transducers are replaced more often than necessary or are calibrated with outdated technology. Low-pressure transducers used in critical applications require calibration after extended use to ensure

Subscribe to Our Blog!

Topics

- Critical Environments (182)

- HVAC/R (179)

- General Industrial (153)

- Building Automation (134)

- General Industrial OEM (92)

- Energy Management (85)

- Test and Measurement (66)

- HVAC/R OEM (58)

- Barometric (44)

- Alternative Fuels (42)

- Medical (40)

- Process/Mfg Tank Level (40)

- Water and Wastewater (39)

- OHV (38)

- Oil and Gas (35)

- Industrial Vacuum (29)

- Calibration (25)

- Semiconductor (25)

- Particle Counting (20)

- Cleanroom Monitoring (17)

- Room Pressure Monitoring (16)

- Trade Show (12)

- cleanroom environment (12)

- Scales (11)

- Environmental Monitoring (10)

- Power Monitoring (10)

- Healthcare (9)

- Power Meters (9)

- Software (9)

- cleanroom monitoring systems (9)

- Case Study (8)

- critical environment technologies (8)

- data centers (8)

- Humidity (7)

- particle counter (6)

- pressure transducers (6)

- LITE room pressure monitor (5)

- hardware and software cleanroom monitoring systems (5)

- setra lite (5)

- Compliance (3)

- Video (3)

- hospital spaces (3)

- FAQ & Troubleshooting (2)

- Monitoring Compounding Pharmacies (2)

- Semiconductor Manufacturing (2)

- agencies that monitor pharmacies (2)

- energy (2)

- hvac (2)

- laboratories (2)

- monitor compound pharmacy (2)

- protected environment (2)

- regulatory compliance (2)

- setra lite features (2)

- usp 797 (2)

- Current Sensors and Transducers (1)

- Current Transformers (1)

- Lithium-Ion Battery (1)

- Pressure (1)

- aerospace cleanrooms (1)

- cems (1)

- digital transformation (1)

- ipv6 multicast (1)

- ipv6 multicast address (1)

- ipv6 multicast address range (1)

- isolation room pressure monitoring (1)

- multicast address ipv6 (1)

- multicast ipv6 (1)

- operating room (1)

- pharma 4.0 (1)

- pressure sensor (1)

- pressure transducer companies (1)

- semi conductor (1)

- sensors and transducers (1)

- setra pressure transducers (1)

- submetering (1)

- sustainability (1)

- temperature monitor (1)

- temperature monitoring for pharmacies (1)

- transducers (1)

- usp 800 (1)

- water (1)

- what does hvac stand for (1)

- what is a transducer (1)

- what is hvac (1)