Selecting a low-differential pressure transducer for critical-care ventilation is one of the most important decisions mechanical designers, engineers and architects can make. These transducers perform precise monitoring and contamination control of isolation-room pressures in critical environments. Properly selected and installed, they help prevent the spread of communicable diseases like tuberculosis (TB).

Setra Blog

There are many risks associated with unmonitored humidity levels in buildings. The most significant of which is the health risks posed to the building’s occupants. Sick Building Syndrome can severely affect occupants’ comfort and productivity, but more alarming are some of the respiratory and other health ailments which can arise from unmonitored humidity levels.

Shock & vibration are two potential mechanical problems for pressure transducers.

Shock is a sudden, unexpected impact that transmits energy to a device in a relatively short time interval. For a pressure transducer, that energy passes through the stainless steel up through the housing. Shock may originate from rough transportation and handling, such as by trucks, forklifts and conveyors. Alternately, shock can be caused simply by dropping the transducer on the shop floor or by an assembler slamming a cabinet door adjacent to it. A transducer may not be damaged by a single shock, but can experience fatigue failure with numerous low-level shocks over the course of its life.

Excessively high temperatures are a common source of pressure transducer difficulties.

Like most other electronic equipment, pressure transducers are effected by temperature, shock and vibrations. They consist of numerous components that only function within specified temperature ranges. Transducers exposed to temperatures exceeding those ranges during the assembly process can be adversely affected.

When selecting multi-range pressure sensors, there are certain things to be cautious of. Often a "one size fits all" pressure transducer is chosen for expected cost savings and inventory control; however this decision turns out to be a bad idea. Issues arise with inaccuracy and poor stability on low range applications where the range output adjustment is simply pushed too far.

Openings Doors in the Operating Room

Recently, a major Boston-area hospital sought to resolve a problem in its operating rooms (OR). Nurses were complaining about how difficult it was to open the doors to the facility’s 23 operating rooms, 5 of which had just been built. They couldn’t understand why they had to pull so hard to open the doors. A veteran hospital HVAC engineering and design consultant did some investigating and recognized the problem of airborne lint on the sensors controlling OR pressurization.

The "central command station" of each floor in a hospital (aka the central nurse's station) plays a critical role in the proper operation of OR suites, isolation wards, and other critical spaces where room condition is crucial. Floor nurses and circulating nurses are tasked with monitoring multiple rooms in their wing, which requires them to physically check each room's condition via the room's condition monitoring device.

On the heels of an economic crisis, the President of the United States signed the American Recovery & Reinvestment Act (ARRA) in 2009 with the goal of:

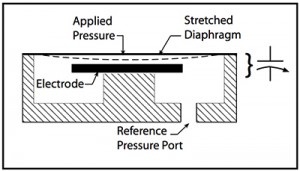

Capacitive pressure transducers have earned a reputation for consistently high accuracy and unmatched long-term stability. These sensors find broad application in areas where characteristics rate from important to vital. A few of these include:

Capacitance based pressure transducers provide many benefits over other technologies. 8 features that should be considered when choosing a pressure transducer are accuracy, minimal mechanical motion, range capabilities, long term stability, high-level output, media compatibility, electromagnetic compatibility and resistant to harsh environments..

Subscribe to Our Blog!

Topics

- Critical Environments (182)

- HVAC/R (179)

- General Industrial (153)

- Building Automation (134)

- General Industrial OEM (92)

- Energy Management (85)

- Test and Measurement (66)

- HVAC/R OEM (58)

- Barometric (44)

- Alternative Fuels (42)

- Medical (40)

- Process/Mfg Tank Level (40)

- Water and Wastewater (39)

- OHV (38)

- Oil and Gas (35)

- Industrial Vacuum (29)

- Calibration (25)

- Semiconductor (25)

- Particle Counting (20)

- Cleanroom Monitoring (17)

- Room Pressure Monitoring (16)

- Trade Show (12)

- cleanroom environment (12)

- Scales (11)

- Environmental Monitoring (10)

- Power Monitoring (10)

- Healthcare (9)

- Power Meters (9)

- Software (9)

- cleanroom monitoring systems (9)

- Case Study (8)

- critical environment technologies (8)

- data centers (8)

- Humidity (7)

- particle counter (6)

- pressure transducers (6)

- LITE room pressure monitor (5)

- hardware and software cleanroom monitoring systems (5)

- setra lite (5)

- Compliance (3)

- Video (3)

- hospital spaces (3)

- FAQ & Troubleshooting (2)

- Monitoring Compounding Pharmacies (2)

- Semiconductor Manufacturing (2)

- agencies that monitor pharmacies (2)

- energy (2)

- hvac (2)

- laboratories (2)

- monitor compound pharmacy (2)

- protected environment (2)

- regulatory compliance (2)

- setra lite features (2)

- usp 797 (2)

- Current Sensors and Transducers (1)

- Current Transformers (1)

- Lithium-Ion Battery (1)

- Pressure (1)

- aerospace cleanrooms (1)

- cems (1)

- digital transformation (1)

- ipv6 multicast (1)

- ipv6 multicast address (1)

- ipv6 multicast address range (1)

- isolation room pressure monitoring (1)

- multicast address ipv6 (1)

- multicast ipv6 (1)

- operating room (1)

- pharma 4.0 (1)

- pressure sensor (1)

- pressure transducer companies (1)

- semi conductor (1)

- sensors and transducers (1)

- setra pressure transducers (1)

- submetering (1)

- sustainability (1)

- temperature monitor (1)

- temperature monitoring for pharmacies (1)

- transducers (1)

- usp 800 (1)

- water (1)

- what does hvac stand for (1)

- what is a transducer (1)

- what is hvac (1)