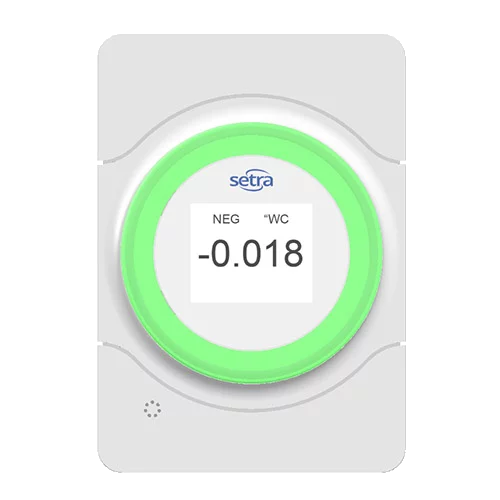

As is common with most technology today, a room pressure monitor (RPM) can quickly be obsoleted by technological advances. With such rapid improvements in technology, it is crucial to select and RPM for your critical environment that won't be obsoleted by new technology in a year. Setra Flex Environmental Room Monitor is a high-end monitoring and control solution that helps hospitals meet the ever-changing standards of a variety of applications:

Setra Blog

Critical environments are spaces where highly controlled processes take place. These room conditions prioritize safety of personnel and the protection of assets. Poor environmental control in these high-consequence applications can put people, processes, or products at risk. Examples of critical environments include:

We recently interviewed one of our sales managers about Setra FLEX. He answered some of the most common questions related to FLEX and its capabilities as a hub.

Undergoing renovation and expansion leads to a hospital reconsidering its critical environment monitoring for the present and the future. The medical facility in question was looking for room pressure monitors that would meet existing and any new codes and guidelines released in upcoming years. They didn't want to install room pressure monitors to be only minimally code compliant; rather, they were looking to meet requirements and monitor many ASHRAE Standard 170 spaces that don't strictly require monitors. Monitoring is crucial for proper cleanliness conditions, and the Joint Commission and CMS inspectors tend to scrutinize all ASHRAE 170 pressurized spaces.

We recently interviewed one of our sales managers about the Setra Lite. He answered some of the most common questions around this innovate product.

October 29, 2019

Does Your Room Pressure Indicator Still Require a Ping-Pong Ball? Maybe It's Time to Upgrade

Hospitals and other critical environments contain several spaces that require pressurization. Highly critical spaces require full environmental room monitoring. However, a number of other spaces still require pressurization but do not require a room monitor. According to ASHRAE Standard-170, spaces like this include:

For a hospital to be compliant with ventilation guidelines (such as ASHRAE Standard-170), proper pressurization must be maintained in several spaces. Some of these spaces, like a linen closet, call for pressurization but do not require monitoring beyond a simple tissue test inspection.

Operating rooms (ORs) are among the most thoroughly regulated spaces in a hospital. As a room where patients are particularly at risk of contracting an airborne infection, patient safety is a priority. A successful surgery relies on both the skill of medical professionals and the integrity of the space. Controlling this critical environment with the proper equipment keeps patients protected from contagions.

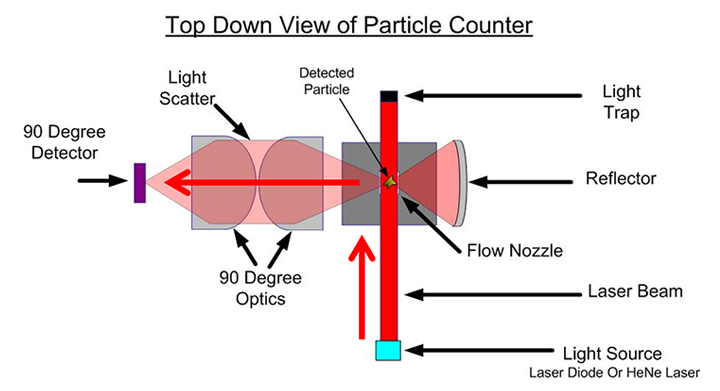

Hospitals face a number of daunting tasks each day without also having to worry about the performance of the equipment on which they rely. The particular medical facility in question experienced abundant issues related to the products they employed. A lack of after-sale support combined with the unsophisticated UI of room pressure monitors and the vendor's reluctance to partner with the facility's BMS controls engineers escalated into long-term compatibility obstacles with the other networked devices. Coming up against these issues led the facility to realize they needed simple and intuitive customizable features that didn't require specialized programming knowledge to set up. In addition to all these issues related to room pressure monitors, they were searching for a solution to make their compounding pharmacy USP 800 compliant with regular particle counting, which they define as an interval of once every 15 minutes.

To continue operating, a critical environment must meet many safety standards to keep their space free of harmful particles. If an environment is not monitored, it can be easily contaminated by harmful particles such as mold. Air sampling is one of the most common ways to monitor for - and thus prevent - mold. Viable and non-viable air sampling can be employed in detecting mold and other harmful particles in the air. Not monitoring for those particles can lead to disaster.

Subscribe to Our Blog!

Topics

- Critical Environments (182)

- HVAC/R (179)

- General Industrial (153)

- Building Automation (134)

- General Industrial OEM (92)

- Energy Management (85)

- Test and Measurement (66)

- HVAC/R OEM (58)

- Barometric (44)

- Alternative Fuels (42)

- Medical (40)

- Process/Mfg Tank Level (40)

- Water and Wastewater (39)

- OHV (38)

- Oil and Gas (35)

- Industrial Vacuum (29)

- Calibration (25)

- Semiconductor (25)

- Particle Counting (18)

- Cleanroom Monitoring (17)

- Room Pressure Monitoring (16)

- Trade Show (12)

- cleanroom environment (12)

- Scales (11)

- Environmental Monitoring (10)

- Power Monitoring (10)

- Healthcare (9)

- Power Meters (9)

- Software (9)

- cleanroom monitoring systems (9)

- Case Study (8)

- critical environment technologies (8)

- Humidity (7)

- data centers (7)

- particle counter (6)

- pressure transducers (6)

- LITE room pressure monitor (5)

- hardware and software cleanroom monitoring systems (5)

- setra lite (5)

- Compliance (3)

- Video (3)

- hospital spaces (3)

- FAQ & Troubleshooting (2)

- Monitoring Compounding Pharmacies (2)

- Semiconductor Manufacturing (2)

- agencies that monitor pharmacies (2)

- energy (2)

- hvac (2)

- laboratories (2)

- monitor compound pharmacy (2)

- protected environment (2)

- regulatory compliance (2)

- setra lite features (2)

- usp 797 (2)

- Current Sensors and Transducers (1)

- Current Transformers (1)

- Pressure (1)

- aerospace cleanrooms (1)

- cems (1)

- digital transformation (1)

- ipv6 multicast (1)

- ipv6 multicast address (1)

- ipv6 multicast address range (1)

- isolation room pressure monitoring (1)

- multicast address ipv6 (1)

- multicast ipv6 (1)

- operating room (1)

- pharma 4.0 (1)

- pressure sensor (1)

- pressure transducer companies (1)

- semi conductor (1)

- sensors and transducers (1)

- setra pressure transducers (1)

- submetering (1)

- sustainability (1)

- temperature monitor (1)

- temperature monitoring for pharmacies (1)

- transducers (1)

- usp 800 (1)

- water (1)

- what does hvac stand for (1)

- what is a transducer (1)

- what is hvac (1)