One of the greatest fears in the general population is the rapid spread of infectious disease. While there are many strategies employed to prevent these infectious diseases from becoming an outbreak, the only way to treat patients without risking the spread of disease is through the use of isolation rooms. Isolation rooms are designed to prevent contaminated particles from spreading beyond a quarantined area by ensuring air is exhausted from the room and filtered through a high-efficiency particulate air (HEPA) filter before it is vented outside of the building.

Setra Blog

Monitoring critical environments - such as cleanrooms, operating rooms, and compounding pharmacies - is paramount to maintain safety and remain compliant with regulatory standards. In these critical spaces, it is often required to monitor multiple environmental parameters.

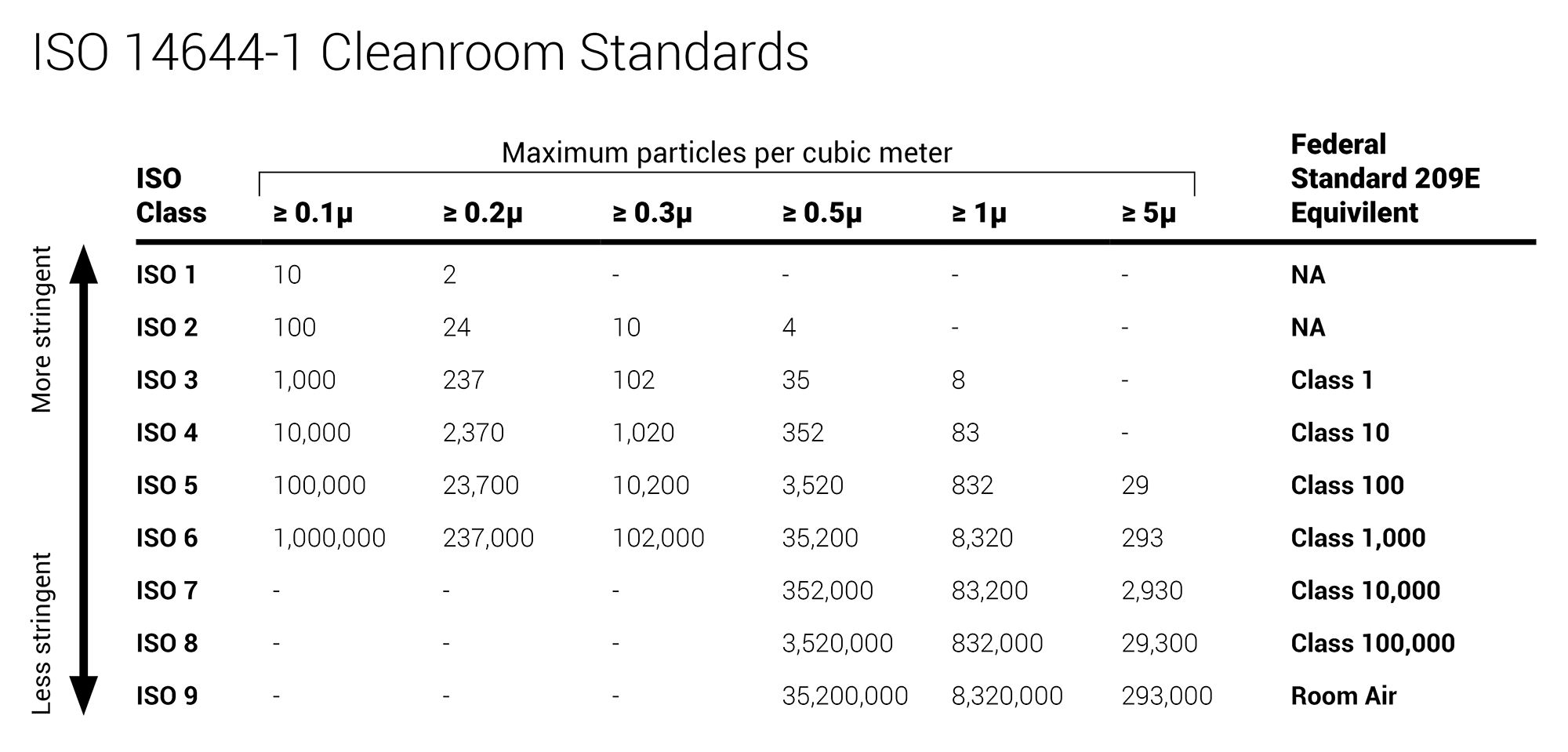

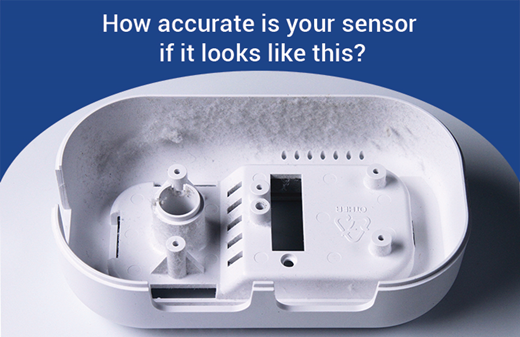

OEM and mechanical parts suppliers adopting ISO Standards is increasingly common throughout the US, driven by a spike in industry demand for components manufactured in ISO compliant factories. In addition to existing and increasing demand for ISO compliance in clean rooms, healthcare spaces, and laboratories, manufacturing facilities like automotive, electronics, loT, and industrial are now adapting to observe these standards. To be ISO compliant, all of these spaces need highly accurate, reliable, and NIST-traceable sensors for monitoring.

For decades, hot-wire anemometers have been widely used throughout hospitals to ensure proper pressurization in critical spaces such as operating rooms and isolation rooms.

When selecting a particle counter, it is necessary to consider what building automation network it can communicate with. Examining the available options helps to ensure the particle counter will connect to your existing network.

Building on the strengths of the Setra FLEX, FLEX-RC adds control capability to the monitor and alarming functions. With the added control capability, FLEX-RC can help manage an environment in a number of ways.

Nosocomial infections (also known as Hospital-Acquired Infections, Healthcare-Associated Infections, or HAIs) can result in otherwise avoidable extended hospital stays, readmittance, follow-up treatments, and even death. HAIs can often spread via airborne transmission, which emphasizes the need for proper room pressurization to contain hazardous particles. Operating rooms (ORs) are an area where patients are especially at risk for contracting infections. 2.5µm particles are an important leading indicator of the potential presence of contaminants that could put the patient at risk. The best opportunity to manage the risk of infections is by limiting 2.5µm particles in a space.

Many HVAC, critical environments, and industrial applications employ temperature and relative humidity (T/RH) sensors. But exactly how many T/RH sensors does an application require? It is difficult to spec the exact requirements for certain applications for a variety of reasons. No two applications are identical, and thus no two spaces require the same number of T/RH sensors. As each application is unique, the number of sensors needed depends on several factors, including:

Inhaling airborne particles can put both critical patients and healthcare staff at risk for detrimental health issues. Controlling these particles is necessary for protecting both staff and occupants of nearby rooms from exposure to infectious particles. To maintain safety in a hospital, it is crucial to monitor both differential pressure and particle counts in anterooms.

Critical environments can have a variety of layouts depending on the purpose of the space. Frequently, these critical environments will have a multi-room setup. Some examples of a multi-room setup are an isolation room and anteroom or a cleanroom, gown up room, and clean storage area.

Subscribe to Our Blog!

Topics

- Critical Environments (182)

- HVAC/R (179)

- General Industrial (153)

- Building Automation (134)

- General Industrial OEM (92)

- Energy Management (85)

- Test and Measurement (66)

- HVAC/R OEM (58)

- Barometric (44)

- Alternative Fuels (42)

- Medical (40)

- Process/Mfg Tank Level (40)

- Water and Wastewater (39)

- OHV (38)

- Oil and Gas (35)

- Industrial Vacuum (29)

- Calibration (25)

- Semiconductor (25)

- Particle Counting (20)

- Cleanroom Monitoring (17)

- Room Pressure Monitoring (16)

- Trade Show (12)

- cleanroom environment (12)

- Scales (11)

- Environmental Monitoring (10)

- Power Monitoring (10)

- Healthcare (9)

- Power Meters (9)

- Software (9)

- cleanroom monitoring systems (9)

- Case Study (8)

- critical environment technologies (8)

- data centers (8)

- Humidity (7)

- particle counter (6)

- pressure transducers (6)

- LITE room pressure monitor (5)

- hardware and software cleanroom monitoring systems (5)

- setra lite (5)

- Compliance (3)

- Video (3)

- hospital spaces (3)

- FAQ & Troubleshooting (2)

- Monitoring Compounding Pharmacies (2)

- Semiconductor Manufacturing (2)

- agencies that monitor pharmacies (2)

- energy (2)

- hvac (2)

- laboratories (2)

- monitor compound pharmacy (2)

- protected environment (2)

- regulatory compliance (2)

- setra lite features (2)

- usp 797 (2)

- Current Sensors and Transducers (1)

- Current Transformers (1)

- Lithium-Ion Battery (1)

- Pressure (1)

- aerospace cleanrooms (1)

- cems (1)

- digital transformation (1)

- ipv6 multicast (1)

- ipv6 multicast address (1)

- ipv6 multicast address range (1)

- isolation room pressure monitoring (1)

- multicast address ipv6 (1)

- multicast ipv6 (1)

- operating room (1)

- pharma 4.0 (1)

- pressure sensor (1)

- pressure transducer companies (1)

- semi conductor (1)

- sensors and transducers (1)

- setra pressure transducers (1)

- submetering (1)

- sustainability (1)

- temperature monitor (1)

- temperature monitoring for pharmacies (1)

- transducers (1)

- usp 800 (1)

- water (1)

- what does hvac stand for (1)

- what is a transducer (1)

- what is hvac (1)