Setra Lite™ has long been a trusted visual pressure indicator, providing clear and immediate pressure status readings for critical environments. Now, with key new upgrades, Setra Lite™ offers even greater convenience, adaptability, and visibility to meet the needs of facility managers, maintenance personnel, and staff.

Setra Blog

For aerospace and defense companies manufacturing critical components, quality assurance is crucial. The slightest defect or particle contamination can compromise the safety and reliability of the final product. Therefore, having the right systems in place to assure quality is essential.

Are You Compliant With USP 797 and USP 800 Standards?

Revised standards for USP General Chapter <797> for compounded sterile preparation (CSP) have been finalized and are active as of Nov 1, 2023. These revisions will also affect USP <800> where hazardous drug (HD) compounding is applicable. Both standards include environmental monitoring and management requirements that were not previously enforced and must be met to achieve accreditation through local and national governing bodies. Understanding the conditions and monitoring requirements is critical in ensuring compliance.

If you need help understanding the UPS <797> and USP <800> requirements and want to find compliant solutions, we would be happy to assist! Contact Setra today to talk with our product team and make sure that all of your spaces are compliant.

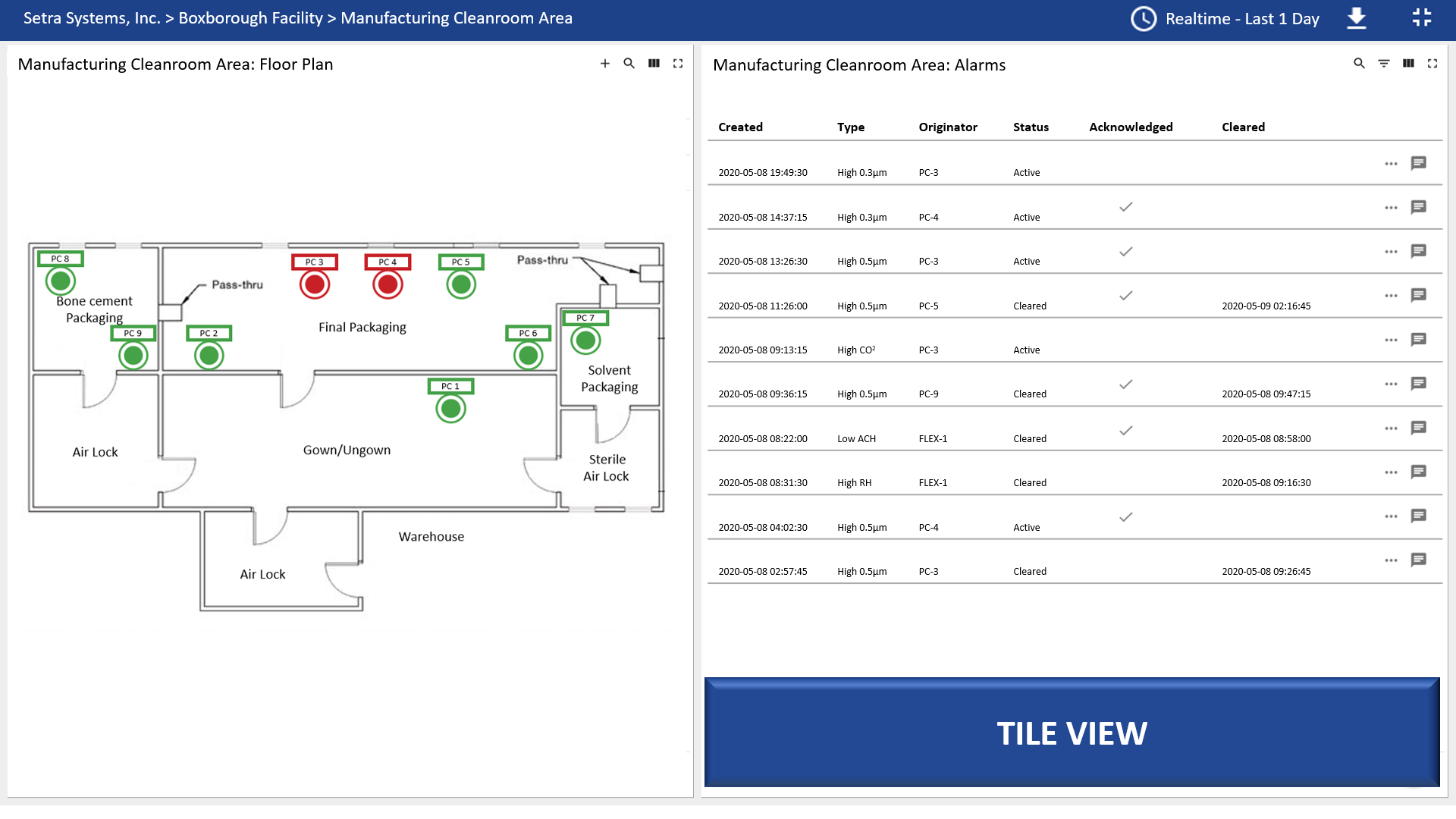

There are many major benefits to be gained from the implementation of a Setra Continuous Environmental Monitoring System (CEMS). The use cases shown below exemplify the ongoing value delivered through this secure, highly available, cloud-based, real-time environmental monitoring, alarming, reporting and data collection platform.

Setra Systems will be exhibiting at the AHR Expo in Las Vegas from January 31 through February 2. In addition to our extensive HVAC and Critical Environments lines, this year Setra will be unveiling several new and exciting products. Come by and see Setra at booth C5712!

It is commonly assumed that organizations need to choose between NIST and ISO. Neither is better than the other and can both be used simultaneously.

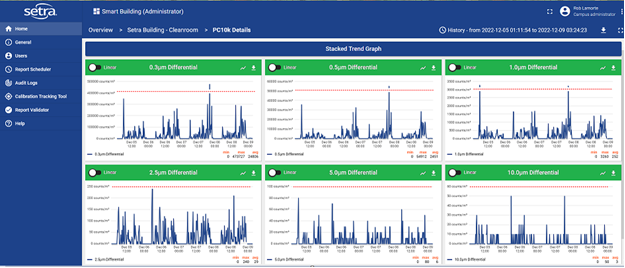

Analyzing trends in data is an important aspect of environmental monitoring for facilities.

Cleanrooms are highly regulated environments that require the continuous monitoring of particle counts. In manufacturing cleanrooms, the safety and quality of products can be affected if too many particles enter the space. Setra’s CEMS provides a solution for environmental data, including particle counting, monitoring and recording needs required by various industries such as:

Cleanrooms are among the most strictly regulated critical environments, often continuously monitoring temperature, differential pressure, and relative humidity, in addition to the size and quantity of every particle. Continuous environmental monitoring helps ensure the quality of products manufactured in those clean spaces.

Setra's CEMS™ offering is an environmental monitoring solution that offers adaptive system of hardware and web-based software providing access to environmental data in real-time. Setra's proprietary CEMS software accepts flexible data inputs and integrates analog and digital hardware, providing a 24/7 centralized monitoring solution with user-friendly data visualizations. With CEMS software, users not only monitor environmental data but also visualize trends and issue alarms, demonstrating patterns in data to influence strategic actions.

Subscribe to Our Blog!

Topics

- Critical Environments (182)

- HVAC/R (179)

- General Industrial (153)

- Building Automation (134)

- General Industrial OEM (92)

- Energy Management (85)

- Test and Measurement (66)

- HVAC/R OEM (58)

- Barometric (44)

- Alternative Fuels (42)

- Medical (40)

- Process/Mfg Tank Level (40)

- Water and Wastewater (39)

- OHV (38)

- Oil and Gas (35)

- Industrial Vacuum (29)

- Calibration (25)

- Semiconductor (25)

- Particle Counting (18)

- Cleanroom Monitoring (17)

- Room Pressure Monitoring (16)

- Trade Show (12)

- cleanroom environment (12)

- Scales (11)

- Environmental Monitoring (10)

- Power Monitoring (10)

- Healthcare (9)

- Power Meters (9)

- Software (9)

- cleanroom monitoring systems (9)

- Case Study (8)

- critical environment technologies (8)

- Humidity (7)

- data centers (7)

- particle counter (6)

- pressure transducers (6)

- LITE room pressure monitor (5)

- hardware and software cleanroom monitoring systems (5)

- setra lite (5)

- Compliance (3)

- Video (3)

- hospital spaces (3)

- FAQ & Troubleshooting (2)

- Monitoring Compounding Pharmacies (2)

- Semiconductor Manufacturing (2)

- agencies that monitor pharmacies (2)

- energy (2)

- hvac (2)

- laboratories (2)

- monitor compound pharmacy (2)

- protected environment (2)

- regulatory compliance (2)

- setra lite features (2)

- usp 797 (2)

- Current Sensors and Transducers (1)

- Current Transformers (1)

- Pressure (1)

- aerospace cleanrooms (1)

- cems (1)

- digital transformation (1)

- ipv6 multicast (1)

- ipv6 multicast address (1)

- ipv6 multicast address range (1)

- isolation room pressure monitoring (1)

- multicast address ipv6 (1)

- multicast ipv6 (1)

- operating room (1)

- pharma 4.0 (1)

- pressure sensor (1)

- pressure transducer companies (1)

- semi conductor (1)

- sensors and transducers (1)

- setra pressure transducers (1)

- submetering (1)

- sustainability (1)

- temperature monitor (1)

- temperature monitoring for pharmacies (1)

- transducers (1)

- usp 800 (1)

- water (1)

- what does hvac stand for (1)

- what is a transducer (1)

- what is hvac (1)