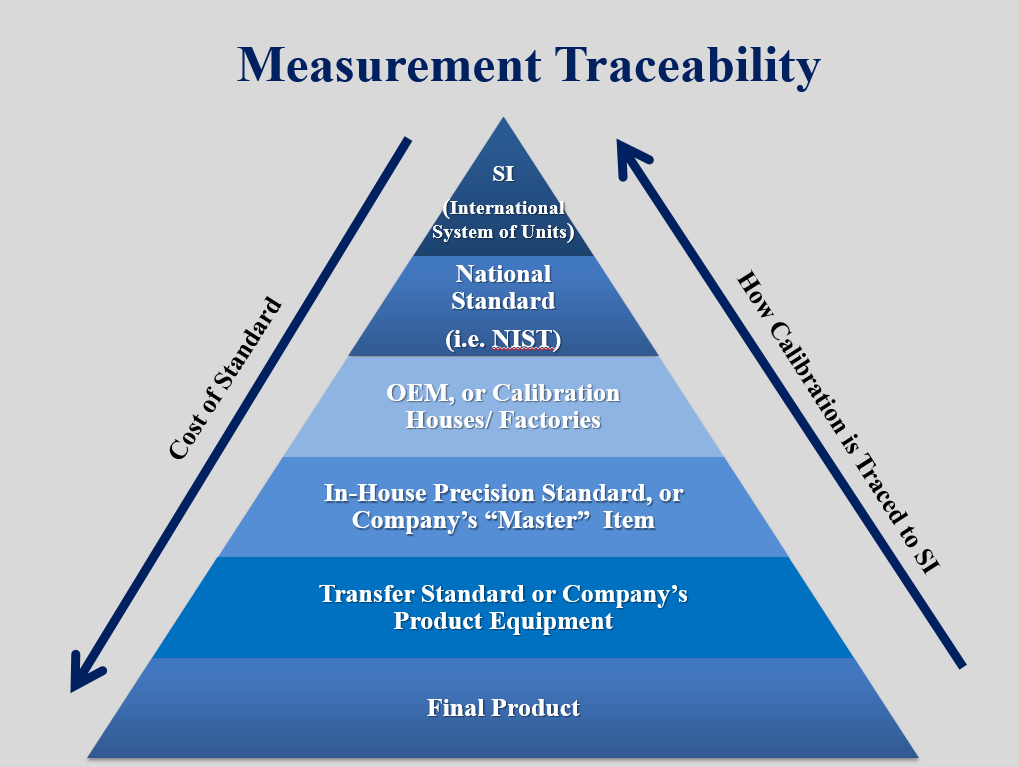

Pressure sensors are used across a variety of industries to provide accurate, real-time data of how a process or system is operating in a given application. But how can you tell if your data is accurate? The most common method to ensure the accuracy of sensor output is to calibrate your sensor against a higher accuracy pressure sensor (calibration standard). Now, how can you tell if your calibration standard is accurate? This is where measurement traceability plays into the calibration process.

Setra Blog

A dynamometer, or "dyno" for short, is a device for measuring force, moment of force (torque), or power. For example, the power produced by an engine, motor or other rotating prime mover can be calculated by simultaneously measuring torque and rotational speed (rpm).

October 24, 2024

What are the differences between a pressure sensor, transducer, transmitter, and switch?

Pressure Transmitter, Transducer, Sensor, or Switch: What are they and how are they different from each other?

The pressure sensing industry features a variety of devices, and their names can be confusing to those unfamiliar with the terminology.

Converting mA to voltage is common in HVAC when working with pressure transducers. Terminology to keep in mind includes:

- 1 mA = 0.001 AMP (short for amperes)

- Amps are referred to as CURRENT

- Resistor values are in OHMS (Ω is the symbol for ohms)

- VOLTAGE is the result of passing amps through a resistor

A variety of pressure sensor designs are available today. Two of the most common sensor types are MEMS and capacitive sensors.

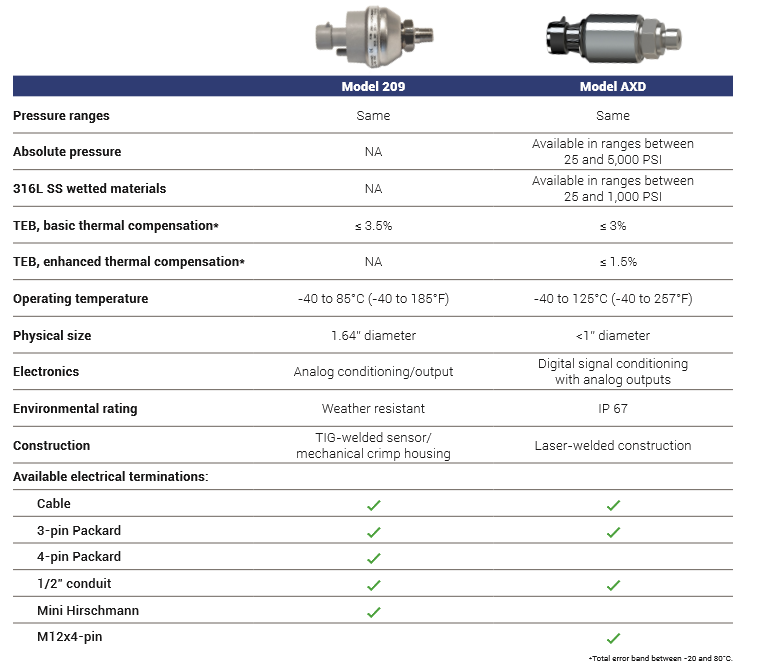

Advancements in technology have created a need for enhanced pressure sensing technology, the next generation of pressure transducers. To meet this new demand, we designed the Model AXD™ Pressure Sensor, the updated and improved version of the Model 209. The Model AXD™ Pressure Sensor is built leveraging the strength of the 209's variable capacitance sensor paired with a new electronics platform. With enhanced performance through digital signal conditioning and a rugged, laser-welded construction, the Model AXD™ Pressure Sensor has the reliability and accuracy necessary for industrial and OEM applications.

Industrial spaces include an extensive range of environments. As such, the products used in those spaces are diverse, varying from gauge to compound to vacuum pressure measuring tools. Pressure sensing in industrial applications helps to keep systems working productively. Demanding industrial applications can require customizable solutions for any type of pressure measurement.

Design engineers have a lot to consider when selecting components for use in end-user products and equipment. Original Equipment Manufacturers (OEMs) that follow a strict Design for Manufacturing and Assembly (DFMA) methodology will have few, if any, problems with pressure transducers. However, OEMs that do not adhere to DFMA practices in their factory increase the likelihood of reoccurring issues, including transducer failure.

Design engineers have a lot to consider when selecting components for use in end-user products and equipment. Original Equipment Manufacturers (OEMs) that follow a strict Design for Manufacturing and Assembly (DFMA) methodology will have few, if any, problems with pressure transducers. However, OEMs that do not adhere to DFMA practices in their factory increase the likelihood of reoccurring issues, including transducer failure.

Design engineers have a lot to consider when selecting components for use in end-user products and equipment. Original Equipment Manufacturers (OEMs) that follow a strict Design for Manufacturing and Assembly (DFMA) methodology will have few, if any, problems with pressure transducers. However, OEMs that do not adhere to DFMA practices in their factory increase the likelihood of reoccurring issues, including transducer failure.

Subscribe to Our Blog!

Topics

- Critical Environments (182)

- HVAC/R (179)

- General Industrial (153)

- Building Automation (134)

- General Industrial OEM (92)

- Energy Management (85)

- Test and Measurement (66)

- HVAC/R OEM (58)

- Barometric (44)

- Alternative Fuels (42)

- Medical (40)

- Process/Mfg Tank Level (40)

- Water and Wastewater (39)

- OHV (38)

- Oil and Gas (35)

- Industrial Vacuum (29)

- Calibration (25)

- Semiconductor (25)

- Particle Counting (18)

- Cleanroom Monitoring (17)

- Room Pressure Monitoring (16)

- Trade Show (12)

- cleanroom environment (12)

- Scales (11)

- Environmental Monitoring (10)

- Power Monitoring (10)

- Healthcare (9)

- Power Meters (9)

- Software (9)

- cleanroom monitoring systems (9)

- Case Study (8)

- critical environment technologies (8)

- Humidity (7)

- data centers (7)

- particle counter (6)

- pressure transducers (6)

- LITE room pressure monitor (5)

- hardware and software cleanroom monitoring systems (5)

- setra lite (5)

- Compliance (3)

- Video (3)

- hospital spaces (3)

- FAQ & Troubleshooting (2)

- Monitoring Compounding Pharmacies (2)

- Semiconductor Manufacturing (2)

- agencies that monitor pharmacies (2)

- energy (2)

- hvac (2)

- laboratories (2)

- monitor compound pharmacy (2)

- protected environment (2)

- regulatory compliance (2)

- setra lite features (2)

- usp 797 (2)

- Current Sensors and Transducers (1)

- Current Transformers (1)

- Pressure (1)

- aerospace cleanrooms (1)

- cems (1)

- digital transformation (1)

- ipv6 multicast (1)

- ipv6 multicast address (1)

- ipv6 multicast address range (1)

- isolation room pressure monitoring (1)

- multicast address ipv6 (1)

- multicast ipv6 (1)

- operating room (1)

- pharma 4.0 (1)

- pressure sensor (1)

- pressure transducer companies (1)

- semi conductor (1)

- sensors and transducers (1)

- setra pressure transducers (1)

- submetering (1)

- sustainability (1)

- temperature monitor (1)

- temperature monitoring for pharmacies (1)

- transducers (1)

- usp 800 (1)

- water (1)

- what does hvac stand for (1)

- what is a transducer (1)

- what is hvac (1)