Maintaining precise control over environmental conditions is essential for modern data centers, where even minor fluctuations in temperature, humidity, and air quality can impact uptime, operational costs, and efficiency. With the rapid growth of data centers supporting AI, machine learning, and digital infrastructure, reliability is critical. Differential pressure sensors play a central role in sustaining this reliability, and accurate calibration is key to their performance. To meet this demand, Setra Systems has partnered with Standard Calibrations, Inc. (SCI), creating a powerful end-to-end solution that ensures accurate sensor performance across all stages of data center operation.

Setra Blog

November 01, 2024

The Importance of Differential Pressure Sensor Accuracy and Calibration in Data Centers

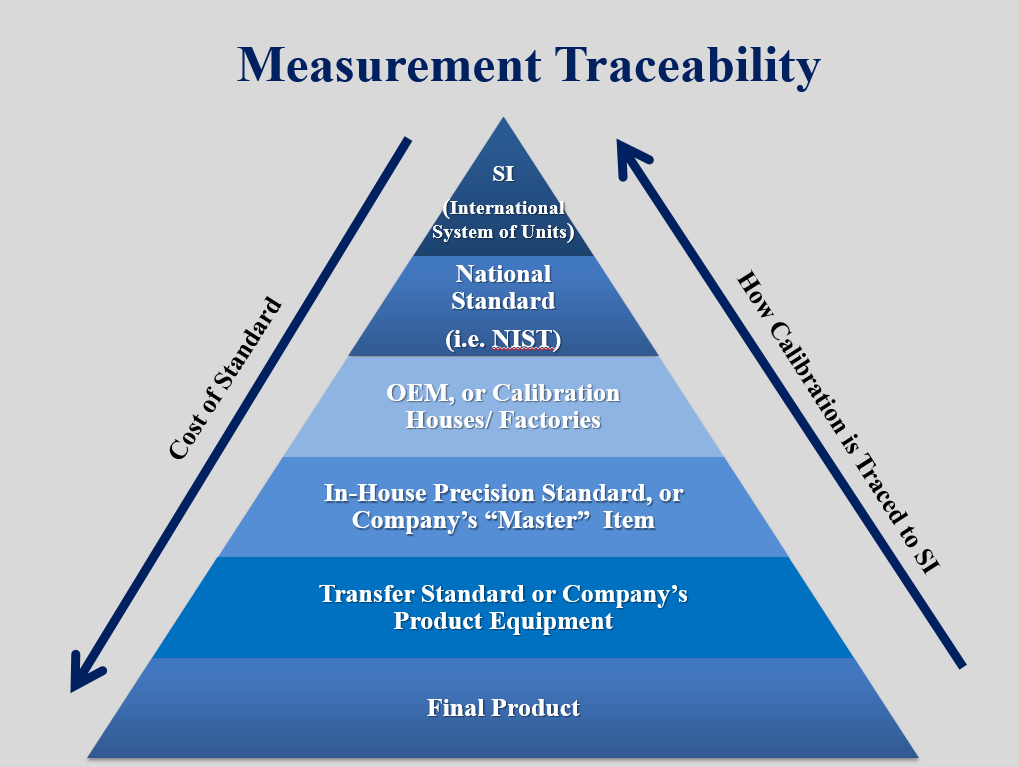

Pressure sensors are used across a variety of industries to provide accurate, real-time data of how a process or system is operating in a given application. But how can you tell if your data is accurate? The most common method to ensure the accuracy of sensor output is to calibrate your sensor against a higher accuracy pressure sensor (calibration standard). Now, how can you tell if your calibration standard is accurate? This is where measurement traceability plays into the calibration process.

A dynamometer, or "dyno" for short, is a device for measuring force, moment of force (torque), or power. For example, the power produced by an engine, motor or other rotating prime mover can be calculated by simultaneously measuring torque and rotational speed (rpm).

October 24, 2024

What are the differences between a pressure sensor, transducer, transmitter, and switch?

Pressure Transmitter, Transducer, Sensor, or Switch: What are they and how are they different from each other?

The pressure sensing industry features a variety of devices, and their names can be confusing to those unfamiliar with the terminology.

In data centers, effective thermal management is critical to maintaining optimal operations, and two primary containment strategies are commonly used: hot aisle containment (HAC) and cold aisle containment (CAC). Both strategies aim to improve cooling efficiency by separating the hot and cold air streams, but they do so in different ways.

Enhancing Data Center Reliability with Setra's Industrial Pressure Sensors

Data centers are the backbone of the digital world, housing critical computer servers that require precise environmental control to function optimally. Worldwide there are well over 10,000 data centers, ranging from expansive hyperscale campuses, small to mid-sized enterprise facilities & colos, and prefabricated modular units, and that number is growing rapidly. As data center design engineers, owners, operators, construction firms, and BAS integrators, maintaining the integrity and performance of these environments is vital.

Converting mA to voltage is common in HVAC when working with pressure transducers. Terminology to keep in mind includes:

- 1 mA = 0.001 AMP (short for amperes)

- Amps are referred to as CURRENT

- Resistor values are in OHMS (Ω is the symbol for ohms)

- VOLTAGE is the result of passing amps through a resistor

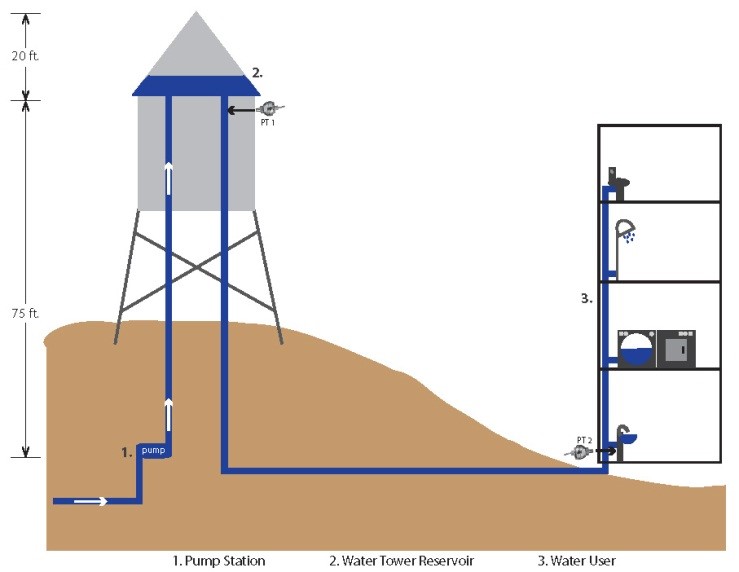

Tank level can be measured in a variety of ways, and each method has its advantages and drawbacks. One of the most common methods for tank level measurements is the hydrostatic method. Hydrostatic pressure is a cost-effective way to measure tank level that doesn’t rely on the measurement being taken directly at the tank, unlike many other methods.

The hydrostatic method uses simple physics to measure tank level. The hydrostatic pressure of a liquid is equal to the height of the liquid above the location of the pressure measurement. The table below demonstrates how certain pressure ranges equal the accuracy of the height measurement.

I2C stands for an integer-integrated circuit. This is a commonly used communication protocol that is flexible enough to be used for a wide variety of applications. Specifically, I2C is a serial communication method with bi-directional two-wire communication. Any sensors and secondary devices only communicate when asked to by the primary.

Pressure transducers all have some degree of variation in output caused by changes in temperature. The best way to compensate for such variation is to employ components on the PCBA that respond to temperature. These components can be fixed in value, adjustable like a potentiometer, or feed into a digital circuit.

Subscribe to Our Blog!

Topics

- Critical Environments (182)

- HVAC/R (179)

- General Industrial (153)

- Building Automation (134)

- General Industrial OEM (92)

- Energy Management (85)

- Test and Measurement (66)

- HVAC/R OEM (58)

- Barometric (44)

- Alternative Fuels (42)

- Medical (40)

- Process/Mfg Tank Level (40)

- Water and Wastewater (39)

- OHV (38)

- Oil and Gas (35)

- Industrial Vacuum (29)

- Calibration (25)

- Semiconductor (25)

- Particle Counting (18)

- Cleanroom Monitoring (17)

- Room Pressure Monitoring (16)

- Trade Show (12)

- cleanroom environment (12)

- Scales (11)

- Environmental Monitoring (10)

- Power Monitoring (10)

- Healthcare (9)

- Power Meters (9)

- Software (9)

- cleanroom monitoring systems (9)

- Case Study (8)

- critical environment technologies (8)

- Humidity (7)

- data centers (7)

- particle counter (6)

- pressure transducers (6)

- LITE room pressure monitor (5)

- hardware and software cleanroom monitoring systems (5)

- setra lite (5)

- Compliance (3)

- Video (3)

- hospital spaces (3)

- FAQ & Troubleshooting (2)

- Monitoring Compounding Pharmacies (2)

- Semiconductor Manufacturing (2)

- agencies that monitor pharmacies (2)

- energy (2)

- hvac (2)

- laboratories (2)

- monitor compound pharmacy (2)

- protected environment (2)

- regulatory compliance (2)

- setra lite features (2)

- usp 797 (2)

- Current Sensors and Transducers (1)

- Current Transformers (1)

- Pressure (1)

- aerospace cleanrooms (1)

- cems (1)

- digital transformation (1)

- ipv6 multicast (1)

- ipv6 multicast address (1)

- ipv6 multicast address range (1)

- isolation room pressure monitoring (1)

- multicast address ipv6 (1)

- multicast ipv6 (1)

- operating room (1)

- pharma 4.0 (1)

- pressure sensor (1)

- pressure transducer companies (1)

- semi conductor (1)

- sensors and transducers (1)

- setra pressure transducers (1)

- submetering (1)

- sustainability (1)

- temperature monitor (1)

- temperature monitoring for pharmacies (1)

- transducers (1)

- usp 800 (1)

- water (1)

- what does hvac stand for (1)

- what is a transducer (1)

- what is hvac (1)