Tomorrow is thanksgiving and host & hostesses across the country are busy shopping for all the tasty treats to be served to their entire guest list that were invited to join them for this holiday. There are many items to prepare for dinner, potatoes, corn, green beans, etc… but the highlight of any thanksgiving meal is the turkey.

Setra Blog

There are 5 things you should know when selecting intrinsically safe pressure transducers there are a number of things to look for.

1. Be assured that the pressure transducer has been significantly modified for intrinsically safe applications — the printed circuit board has been simplified to use low voltage and current, capacitors and inductors have been minimized, etc. Intrinsically safe

One factor that should be considered when selecting an industrial pressure transducer for monitoring high temperature liquids or gases is the operating temperature range of the transducer. This specification is included under environmental data on most manufacturers' data sheets.

Have you ever wanted to build your own Haunted House or Spooky Trail?

I'm sure we've all thought about it one time or another. You know what I'm talking about. Places like amusement parks, fairs, or even a homemade one that your “Halloween Crazed” neighbors down the street built themselves. But how do they work?

Any design engineer must seriously consider the manufacturing environment when looking to select a pressure transducer for inclusion within a refrigeration chiller, pump, engine test equipment, or other machinery. The life of a pressure transducer is proportional to the system design and assembly process.

In the Test and Measurement industry, pressure plays a large part in engine testing and automotive component manufacturing. That’s why wherever you find engines being tested, you’ll likely find transducers measuring everything from air intake pressures to exhaust back-pressures. In the automotive industry, you’ll find transducers measuring everything from tire inflation pressure for dynamometer testing to controlling tool pressure during crankshaft journal burnishing.

See below for the many categories and descriptions of where Test & Measurement transducers are used and why:

The following steps clearly indicate the exact sequence to properly troubleshoot a Setra 2 wire, mil-amp circuit. You must work with the assumption that either the Setra product or the system & circuitry is bad.

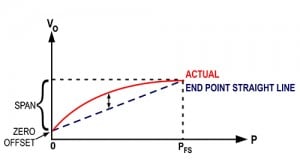

Which method provides better accuracy? Non-linearity as the End Point Method is the relationship of the calibration curve to a specified straight line through its endpoints (i.e. Zero and Full Scale). Best Fit Straight Line (BFSL) method is the relationship of the calibration curve to a calculated straight line that minimizes the error but does not pass through the end points. BFSL method effectively cuts the end point value in half.

Shock & Vibration Are 2 Potential Mechanical Problems for transducer

There are numerous environmental factors that may interfere with the performance of a pressure transducer. Two factors that sometimes overlooked to engineers are shock and vibration. Knowing the system where the pressure transducer is installed can help avoid high shock and vibration conditions, minimizing premature failure of your instrumentation. Before understanding the risks associated with shock and vibration, how a pressure transducer may experience or encounter these effects must be defined.

Shock is a sudden, unexpected impact that transmits energy

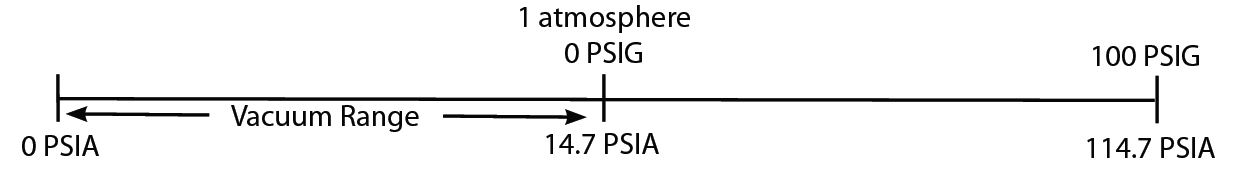

The term vacuum is often misunderstood. Consequently, it is commonly misapplied when discussing pressure measurements and choosing pressure transducers. Pressure is the exertion of force upon an object. However, pressure can be measured in many different ways, depending on the applications.

Subscribe to Our Blog!

Topics

- Critical Environments (182)

- HVAC/R (179)

- General Industrial (153)

- Building Automation (134)

- General Industrial OEM (92)

- Energy Management (85)

- Test and Measurement (66)

- HVAC/R OEM (58)

- Barometric (44)

- Alternative Fuels (42)

- Medical (40)

- Process/Mfg Tank Level (40)

- Water and Wastewater (39)

- OHV (38)

- Oil and Gas (35)

- Industrial Vacuum (29)

- Calibration (25)

- Semiconductor (25)

- Particle Counting (18)

- Cleanroom Monitoring (17)

- Room Pressure Monitoring (16)

- Trade Show (12)

- cleanroom environment (12)

- Scales (11)

- Environmental Monitoring (10)

- Power Monitoring (10)

- Healthcare (9)

- Power Meters (9)

- Software (9)

- cleanroom monitoring systems (9)

- Case Study (8)

- critical environment technologies (8)

- Humidity (7)

- data centers (7)

- particle counter (6)

- pressure transducers (6)

- LITE room pressure monitor (5)

- hardware and software cleanroom monitoring systems (5)

- setra lite (5)

- Compliance (3)

- Video (3)

- hospital spaces (3)

- FAQ & Troubleshooting (2)

- Monitoring Compounding Pharmacies (2)

- Semiconductor Manufacturing (2)

- agencies that monitor pharmacies (2)

- energy (2)

- hvac (2)

- laboratories (2)

- monitor compound pharmacy (2)

- protected environment (2)

- regulatory compliance (2)

- setra lite features (2)

- usp 797 (2)

- Current Sensors and Transducers (1)

- Current Transformers (1)

- Pressure (1)

- aerospace cleanrooms (1)

- cems (1)

- digital transformation (1)

- ipv6 multicast (1)

- ipv6 multicast address (1)

- ipv6 multicast address range (1)

- isolation room pressure monitoring (1)

- multicast address ipv6 (1)

- multicast ipv6 (1)

- operating room (1)

- pharma 4.0 (1)

- pressure sensor (1)

- pressure transducer companies (1)

- semi conductor (1)

- sensors and transducers (1)

- setra pressure transducers (1)

- submetering (1)

- sustainability (1)

- temperature monitor (1)

- temperature monitoring for pharmacies (1)

- transducers (1)

- usp 800 (1)

- water (1)

- what does hvac stand for (1)

- what is a transducer (1)

- what is hvac (1)