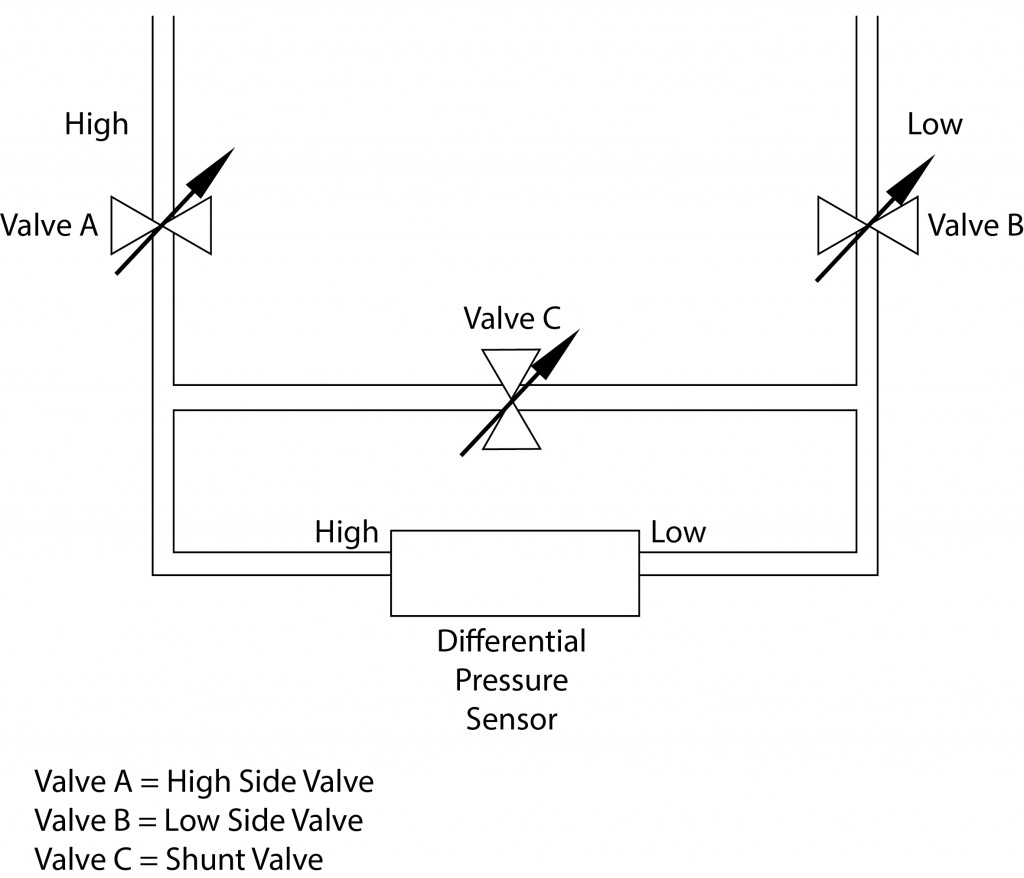

For high line pressure, high differential pressure applications

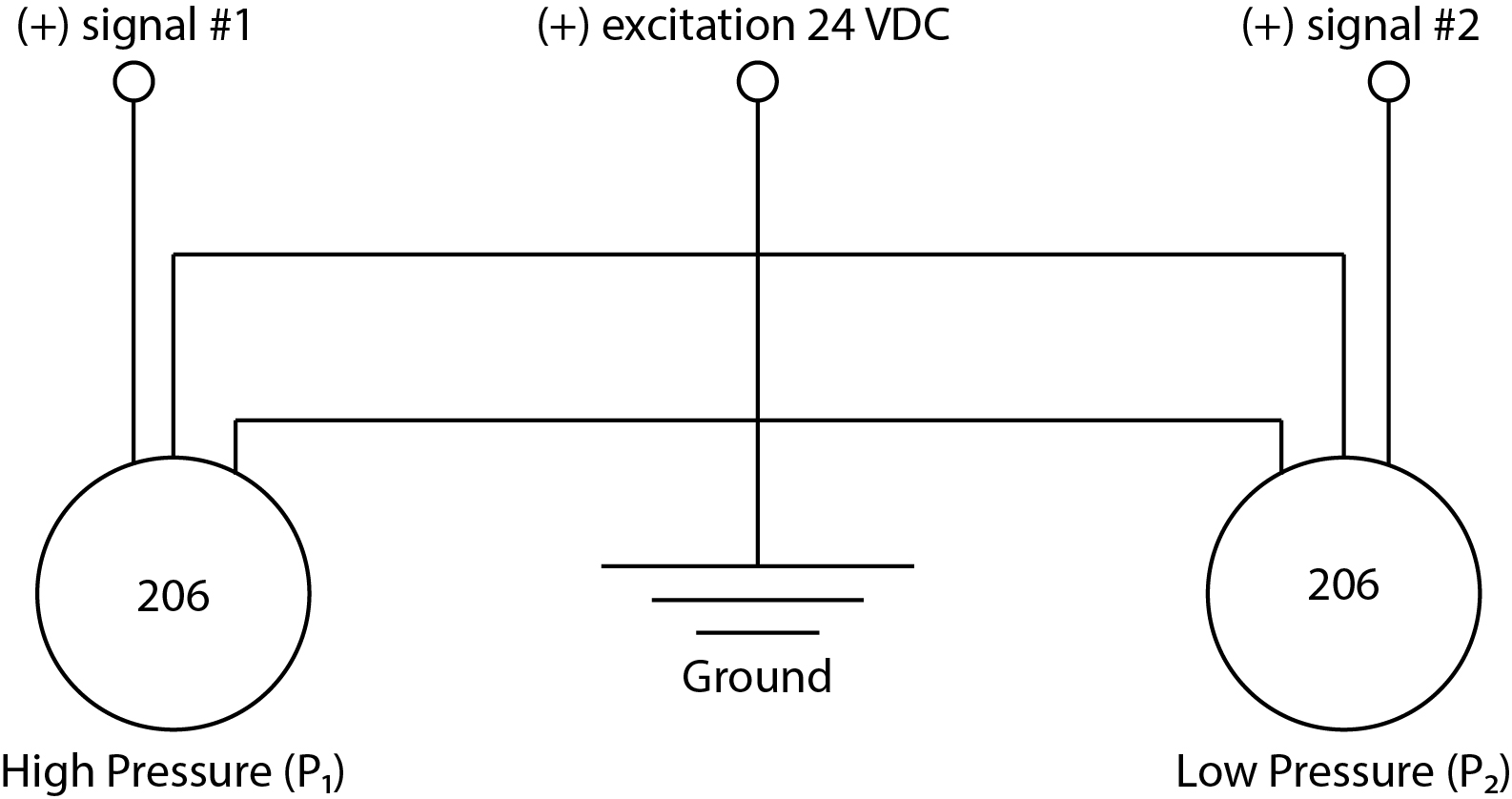

The pressure difference across an orifice plate, filter, pump, valve, etc. can be sensed with two pressure transducers such as the Model 206. One transducer measures the high side pressure (P1) while the other measure the low side pressure (P2). Pressure media can be any liquid or gas compatible with 17-4 pH stainless steel.