A variety of pressure sensor designs are available today. Two of the most common sensor types are MEMS and capacitive sensors.

Setra Blog

For referring to variable capacitive sensing technologies, four specific terms are commonly used: pressure transmitters, transducers, sensors, and switches. Capacitance is the detection and measurement of pressure by the change in voltage across a capacitor. The capacitance of sensing technology can be fixed or adjustable and varies dependent on the application. Capacitive sensing technology is highly precise, boasting accuracies of up to ± 0.07% of full scale. This pressure sensing technology is used for applications where a high degree of accuracy is crucial, such as engine test stands and pressure decay leak detection.

Thermal compensation is used to offset sensor performance when efficiency is impacted by fluctuations in temperature. Transducers used for precise testing and measurement applications, such as in engine test stands, undergo thermal compensation. Many transducers used in other critical applications may be thermally compensated. Thermally compensating sensors is crucial as temperature can have a significant impact on performance if not accounted for. This step in manufacturing counteracts the effects from changes in temperature that can influence the accuracy of a transducer's output. Thermal influence the accuracy of a transducer's output. Thermal compensation helps reduce the impact of temperature changes on sensitive components.

Many companies in today's world are working to help support the urgent need for ventilator manufacturing. For this application, Setra's two smallest pressure sensors can function for OEMs, our Models 210 and 263.

In HVAC and refrigeration, pressure sensors monitor pressure changes to indicate when issues arise. Drops in pressure can alert technicians of needed maintenance or larger problems. Within the variety of HVAC applications are also numerous available sensors for every environment. For example, industrial pressure sensors can be used to measure the pressure of fluorocarbon refrigerants, the pressure of chilled water in chiller systems, or the pressure of refrigerant in a refrigeration system.

Today's world depends heavily on the production of ventilators and the safety of critical environments. However, said safety is not dependent on room pressure monitors alone. High accuracy industrial pressure sensors contribute to production efforts for ventilators.

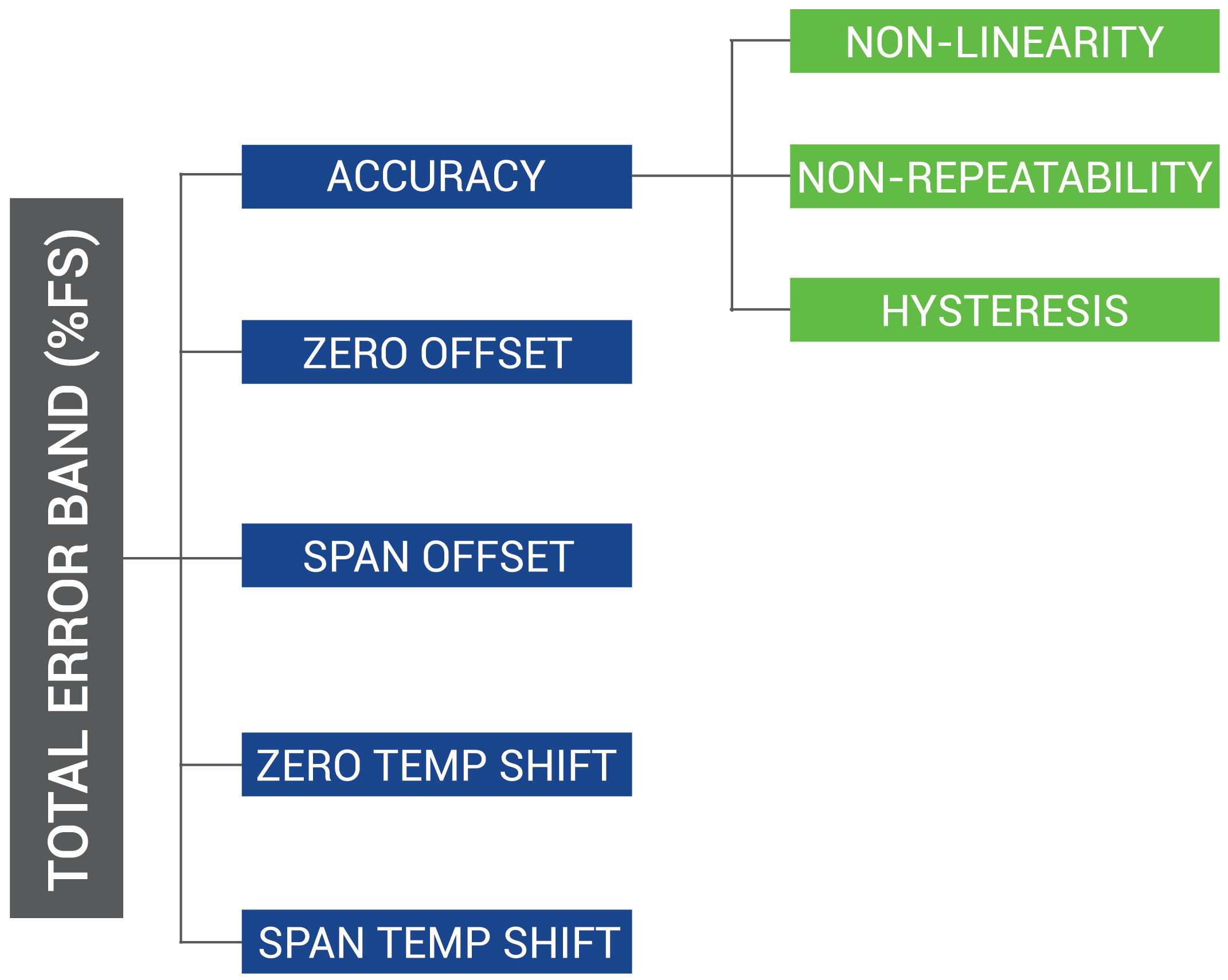

When designing a new system or device, there are enough problems to solve without worrying about the reliability of pressure transducers. Choosing a sensor with a low total error band can make designing the system easier.

Challenging applications like off-highway and specialty vehicles require dependable pressure transducers with the ability to survive a potentially extreme range of environmental and performance requirements including high overpressure conditions, wide operating temperature ranges, and wide humidity and moisture situations. Specialty vehicles can include:

Many alternative fuels depend on precise measurements for gage, absolute, or compound pressure. Transducers in some of these applications endure potentially corrosive environments. To keep up with the demands of renewable energy applications, adaptable capacitive sensing technology can measure a variety of pressure types. Alternative fuel applications for the AXD and AXDH sensors are varied and include compression, storage and dispensing systems, hydrogen generators, and hydrogen fuel cell systems used to produce electricity.

Railways are essential for countries to function. These systems with massive machines can transport almost anything and require immense engines to successfully make their trips. Mechanical failures in locomotives can lead to costly delays and potentially dangerous and damaging situations. The control system helps prevent this issue by monitoring and measuring fluid levels to guarantee the engine and related mechanical systems can operate properly. Pressure transducers play a critical role in ensuring all systems operate efficiently and safely.

Subscribe to Our Blog!

Topics

- Critical Environments (182)

- HVAC/R (179)

- General Industrial (153)

- Building Automation (134)

- General Industrial OEM (92)

- Energy Management (85)

- Test and Measurement (66)

- HVAC/R OEM (58)

- Barometric (44)

- Alternative Fuels (42)

- Medical (40)

- Process/Mfg Tank Level (40)

- Water and Wastewater (39)

- OHV (38)

- Oil and Gas (35)

- Industrial Vacuum (29)

- Calibration (25)

- Semiconductor (25)

- Particle Counting (20)

- Cleanroom Monitoring (17)

- Room Pressure Monitoring (16)

- Trade Show (12)

- cleanroom environment (12)

- Scales (11)

- Environmental Monitoring (10)

- Power Monitoring (10)

- Healthcare (9)

- Power Meters (9)

- Software (9)

- cleanroom monitoring systems (9)

- Case Study (8)

- critical environment technologies (8)

- data centers (8)

- Humidity (7)

- particle counter (6)

- pressure transducers (6)

- LITE room pressure monitor (5)

- hardware and software cleanroom monitoring systems (5)

- setra lite (5)

- Compliance (3)

- Video (3)

- hospital spaces (3)

- FAQ & Troubleshooting (2)

- Monitoring Compounding Pharmacies (2)

- Semiconductor Manufacturing (2)

- agencies that monitor pharmacies (2)

- energy (2)

- hvac (2)

- laboratories (2)

- monitor compound pharmacy (2)

- protected environment (2)

- regulatory compliance (2)

- setra lite features (2)

- usp 797 (2)

- Current Sensors and Transducers (1)

- Current Transformers (1)

- Lithium-Ion Battery (1)

- Pressure (1)

- aerospace cleanrooms (1)

- cems (1)

- digital transformation (1)

- ipv6 multicast (1)

- ipv6 multicast address (1)

- ipv6 multicast address range (1)

- isolation room pressure monitoring (1)

- multicast address ipv6 (1)

- multicast ipv6 (1)

- operating room (1)

- pharma 4.0 (1)

- pressure sensor (1)

- pressure transducer companies (1)

- semi conductor (1)

- sensors and transducers (1)

- setra pressure transducers (1)

- submetering (1)

- sustainability (1)

- temperature monitor (1)

- temperature monitoring for pharmacies (1)

- transducers (1)

- usp 800 (1)

- water (1)

- what does hvac stand for (1)

- what is a transducer (1)

- what is hvac (1)