Many industrial applications rely on pressure transducers to efficiently and safely operate and maintain equipment. If a pressure sensor fails, it can cause the entire control system to fail and lead to inoperable equipment or system down time; depending on the type of system, significant damage can occur to the equipment and surrounding environment. For systems experiencing periodic pressure spikes, damage due to a failed pressure sensor can often be prevented if the sensor selection processes considers overpressure resilience.

Setra Blog

Recently, Setra hosted a webinar presenting the Model AXD. The Model AXD™ Pressure Sensor is the platform for Setra's industrial transducer future. It is the best performing low range and vacuum sensor in this price range on the market.

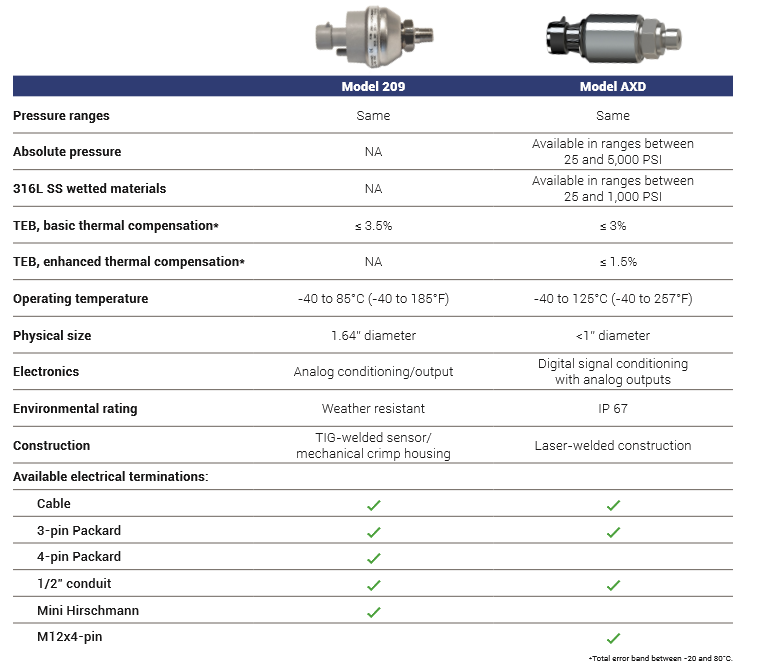

Advancements in technology have created a need for enhanced pressure sensing technology, the next generation of pressure transducers. To meet this new demand, we designed the Model AXD™ Pressure Sensor, the updated and improved version of the Model 209. The Model AXD™ Pressure Sensor is built leveraging the strength of the 209's variable capacitance sensor paired with a new electronics platform. With enhanced performance through digital signal conditioning and a rugged, laser-welded construction, the Model AXD™ Pressure Sensor has the reliability and accuracy necessary for industrial and OEM applications.

Heavy-duty equipment for both indoor and outdoor applications typically requires measuring water or liquid pressure to some degree. This equipment endures harsh conditions and a wide range of temperatures which can lead to water freezing inside pressure transducers, particularly when equipment is idle. Common applications where this occurs are:

Demanding applications like off-highway vehicles and test/measurement require durable pressure transducers with overpressure capabilities. Without them, projects can come to a standstill if a single pressure transducer fails.

Industrial spaces include an extensive range of environments. As such, the products used in those spaces are diverse, varying from gauge to compound to vacuum pressure measuring tools. Pressure sensing in industrial applications helps to keep systems working productively. Demanding industrial applications can require customizable solutions for any type of pressure measurement.

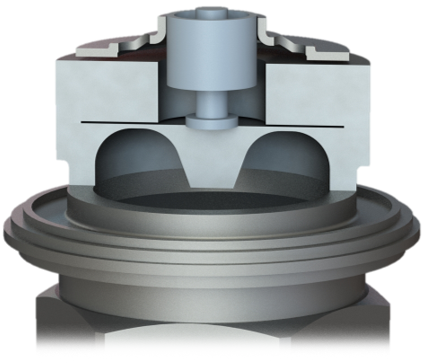

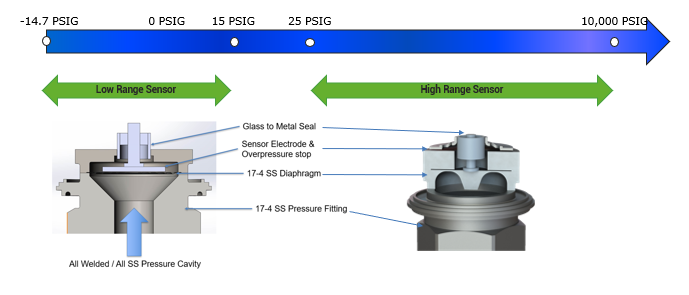

Now available, the Model AXD™ Pressure Sensor is Setra's most versatile pressure transducer yet. Built for high performance applications, the Model AXD features a patented overpressure stop that allows the sensor to recover from overpressure conditions up to 8x the rated range. With a specially designed diaphragm for each pressure range, the Model AXD can measure pressure from 1 PSI to 10,000 PSI full scale. The Model AXD can operate over a wide temperature range from -40 to 125°C.

Many HVAC, critical environments, and industrial applications employ temperature and relative humidity (T/RH) sensors. But exactly how many T/RH sensors does an application require? It is difficult to spec the exact requirements for certain applications for a variety of reasons. No two applications are identical, and thus no two spaces require the same number of T/RH sensors. As each application is unique, the number of sensors needed depends on several factors, including:

Design engineers have a lot to consider when selecting components for use in end-user products and equipment. Original Equipment Manufacturers (OEMs) that follow a strict Design for Manufacturing and Assembly (DFMA) methodology will have few, if any, problems with pressure transducers. However, OEMs that do not adhere to DFMA practices in their factory increase the likelihood of reoccurring issues, including transducer failure.

Design engineers have a lot to consider when selecting components for use in end-user products and equipment. Original Equipment Manufacturers (OEMs) that follow a strict Design for Manufacturing and Assembly (DFMA) methodology will have few, if any, problems with pressure transducers. However, OEMs that do not adhere to DFMA practices in their factory increase the likelihood of reoccurring issues, including transducer failure.

Subscribe to Our Blog!

Topics

- Critical Environments (182)

- HVAC/R (179)

- General Industrial (153)

- Building Automation (134)

- General Industrial OEM (92)

- Energy Management (85)

- Test and Measurement (66)

- HVAC/R OEM (58)

- Barometric (44)

- Alternative Fuels (42)

- Medical (40)

- Process/Mfg Tank Level (40)

- Water and Wastewater (39)

- OHV (38)

- Oil and Gas (35)

- Industrial Vacuum (29)

- Calibration (25)

- Semiconductor (25)

- Particle Counting (18)

- Cleanroom Monitoring (17)

- Room Pressure Monitoring (16)

- Trade Show (12)

- cleanroom environment (12)

- Scales (11)

- Environmental Monitoring (10)

- Power Monitoring (10)

- Healthcare (9)

- Power Meters (9)

- Software (9)

- cleanroom monitoring systems (9)

- Case Study (8)

- critical environment technologies (8)

- Humidity (7)

- data centers (7)

- particle counter (6)

- pressure transducers (6)

- LITE room pressure monitor (5)

- hardware and software cleanroom monitoring systems (5)

- setra lite (5)

- Compliance (3)

- Video (3)

- hospital spaces (3)

- FAQ & Troubleshooting (2)

- Monitoring Compounding Pharmacies (2)

- Semiconductor Manufacturing (2)

- agencies that monitor pharmacies (2)

- energy (2)

- hvac (2)

- laboratories (2)

- monitor compound pharmacy (2)

- protected environment (2)

- regulatory compliance (2)

- setra lite features (2)

- usp 797 (2)

- Current Sensors and Transducers (1)

- Current Transformers (1)

- Pressure (1)

- aerospace cleanrooms (1)

- cems (1)

- digital transformation (1)

- ipv6 multicast (1)

- ipv6 multicast address (1)

- ipv6 multicast address range (1)

- isolation room pressure monitoring (1)

- multicast address ipv6 (1)

- multicast ipv6 (1)

- operating room (1)

- pharma 4.0 (1)

- pressure sensor (1)

- pressure transducer companies (1)

- semi conductor (1)

- sensors and transducers (1)

- setra pressure transducers (1)

- submetering (1)

- sustainability (1)

- temperature monitor (1)

- temperature monitoring for pharmacies (1)

- transducers (1)

- usp 800 (1)

- water (1)

- what does hvac stand for (1)

- what is a transducer (1)

- what is hvac (1)