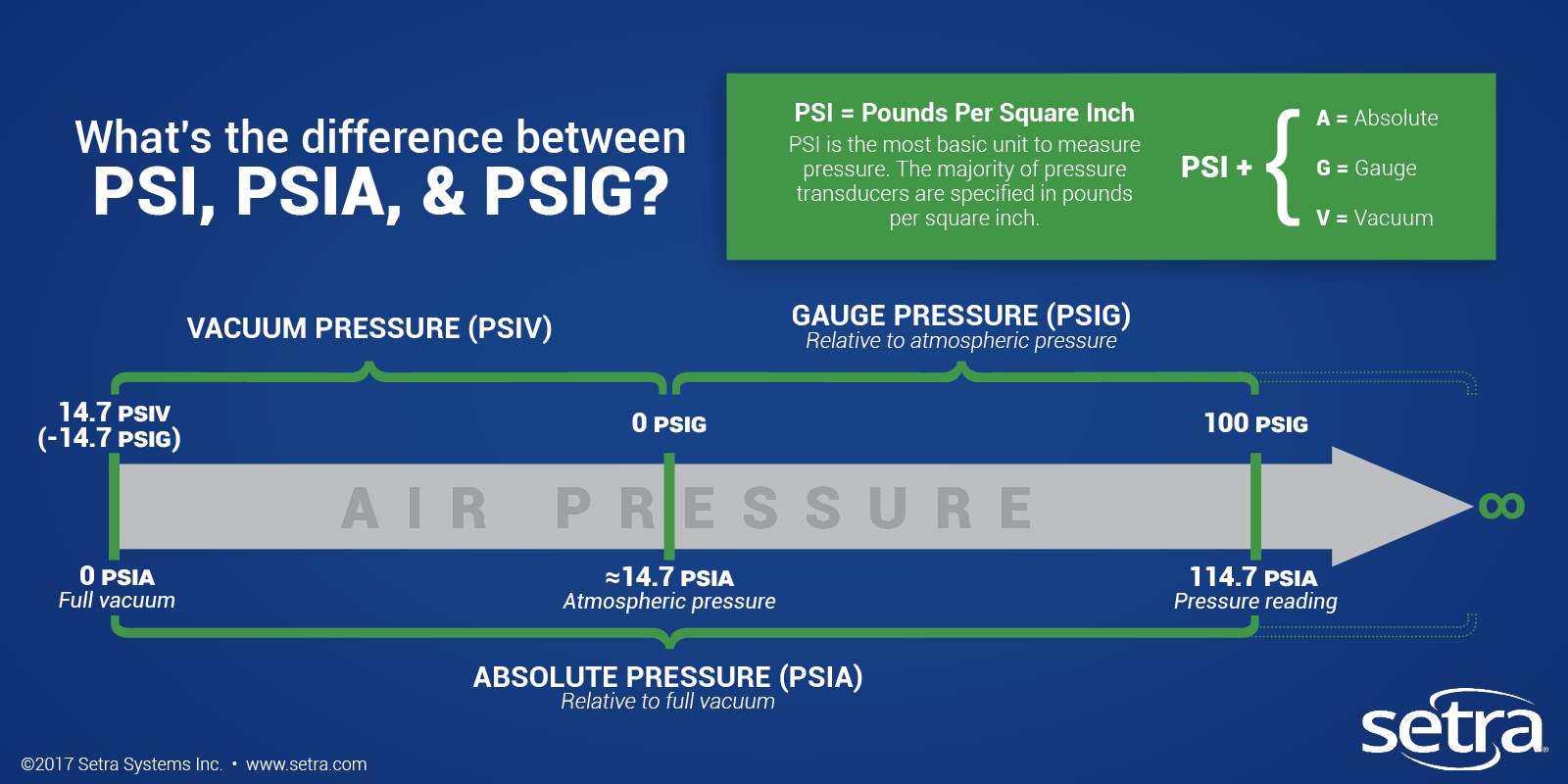

Absolute pressure is the pressure measured relative to a perfect vacuum, which is considered absolute zero pressure. This means it includes the atmospheric pressure in addition to the pressure of the system being measured.

An incredibly diverse array of applications require the measurement of air pressure. Depending on the application, users need to be able to interpret pressure readings in different ways and use appropriate units to reflect those readings accurately.

Absolute Pressure Defined

Absolute pressure is measured relative to a full vacuum. In contrast, the pressure that is measured against atmospheric pressure (also known as barometric pressure) is called gauge pressure. A full vacuum has an absolute pressure reading of 0 PSIA and the average barometric pressure at sea level is ~14.7 PSIA.