Although there are a variety of methods for leak detection, the most common is pressure decay. Other methods can be time consuming and costly, whereas pressure decay leak detection is a simple test that's sensitive to very small leaks. This method is ideal for high-volume industries that require quick accurate tests within their facility. By pressurizing the unit under test (UUT) and then removing it from the pressure source, any detection of pressure loss is a result of a leak within the UUT. Before performing a pressure decay leak detection test, make sure your system is properly setup. After the system is setup, follow the below steps to test the UUT with a differential pressure transducer.

Setra Blog

The consequences of an unplanned leak in an air compressor may be higher than you think. Air leakage can occur in any part of an air system, at any given time. Many users are blindsided by this issue. Air leaks are a significant source of wasted energy, often wasting 20-30% of a compressor’s output. Did you know that unmaintained plants waste at least 20% of air production capacity? In addition to wasting energy, undetected leaks can contribute to financial and operational losses.

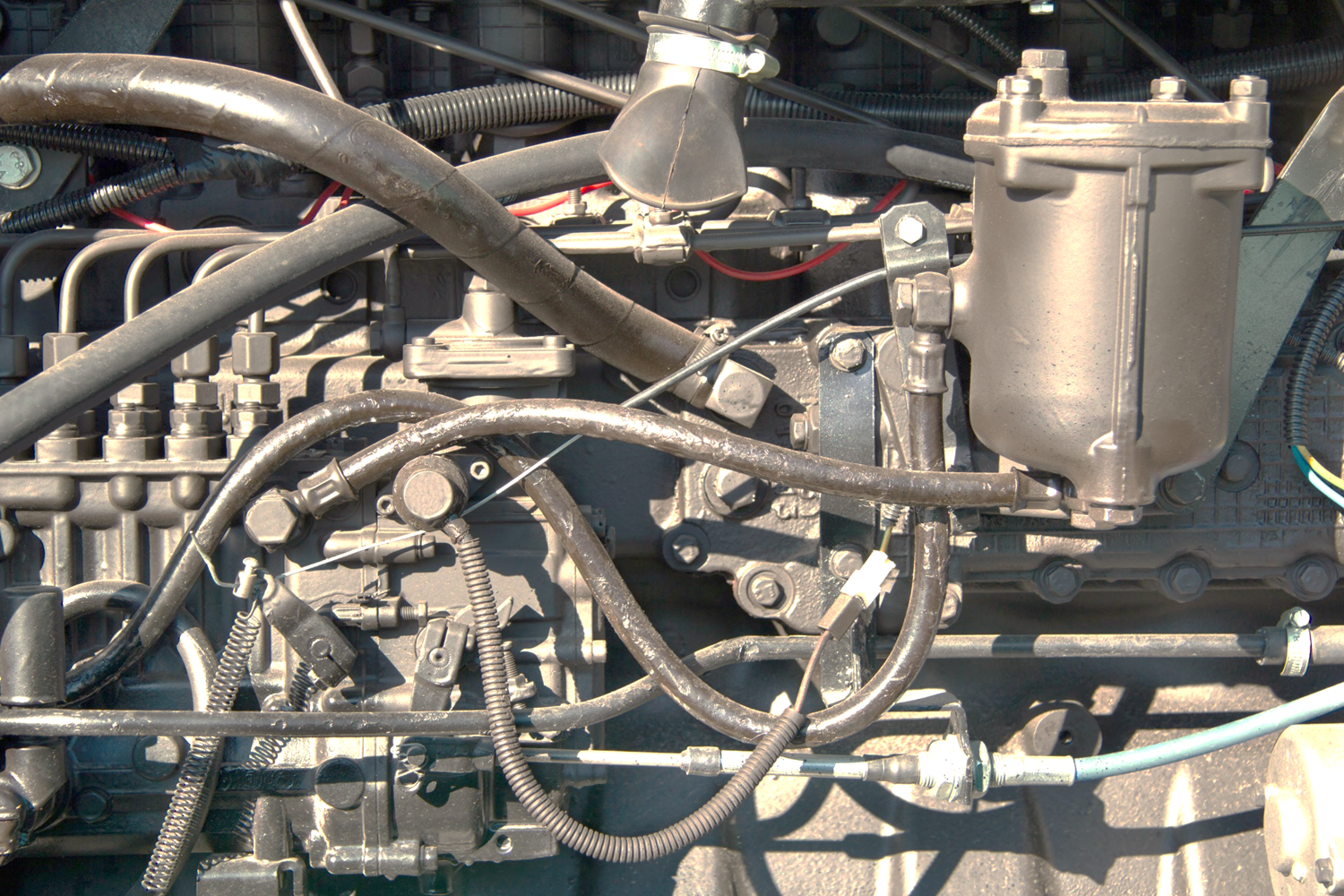

In the test and measurement industry, manufacturers need to test the products they build. Pressure sensors are needed in test stands to measure pressure across various mediums, including air, fuel, coolant, gas. Testing can be expensive and having a reliable sensor eliminates costly downtime.

Whether you are an engineer or a consumer, many daily applications involve capacitance. Capacitance can be measured using a capacitor, however it is not as simple as that. There are three different methods in which the capacitor measures capacitance.

April 28, 2016

Why should you use a unidirectional differential pressure transducer for isolation rooms?

We have gone over the best practices for selecting a unidirectional and a bidirectional differential pressure transducer based on usage and application. So why should you use a unidirectional differential pressure transducer over a bidirectional model for an isolation room? When requiring an increased accuracy reading for positive and negative pressure, it is best to use a unidirectional transducer. For positive pressurized rooms, you can place the low port on the reference area and the high port on the room of concern. For negative pressurized rooms, you place the low port on the negative pressure room of concern and the high port on the pressure reference area.

Material Compatibility refers to a material's resistance to corrosion, rust or stains when it comes in contact with a chemical.

Have you seen a large metal instrument, similar to the picture on the right, floating in the ocean and wondered what that device could be? What you have seen is a buoy (pronounced: boo-ee). A data buoy contains sensors used to monitor and collect atmospheric and oceanographic conditions.

When selecting a filter it is important to select the proper filter type, not only for removing undesirable material from a liquid stream but to ensure the filter meets the needs and requirements of the system. Proper filter selection can be varied amongst industrial applications including water filtration, boilers, and irrigation. Filter selection not only encompasses the media and size of the particle that is being captured, but operational costs also come into play. Below three basic filter types to consider for liquid processing:

Hydrogen is used as a process media across many different industries and applications. Used in OEM equipment, pressure sensors play an important role in the safe, efficient, and reliable operation in material handling equipment, power generation, hydrogen production/distribution and many other applications.

Even with a pressure transducer, it can be very confusing to measure pressure. For one thing it may be diffcult to understand all the different pressure measurement types, and apply its application correctly.

Hopefully this presentation can clear things up:

Subscribe to Our Blog!

Topics

- Critical Environments (182)

- HVAC/R (179)

- General Industrial (153)

- Building Automation (134)

- General Industrial OEM (92)

- Energy Management (85)

- Test and Measurement (66)

- HVAC/R OEM (58)

- Barometric (44)

- Alternative Fuels (42)

- Medical (40)

- Process/Mfg Tank Level (40)

- Water and Wastewater (39)

- OHV (38)

- Oil and Gas (35)

- Industrial Vacuum (29)

- Calibration (25)

- Semiconductor (25)

- Particle Counting (18)

- Cleanroom Monitoring (17)

- Room Pressure Monitoring (16)

- Trade Show (12)

- cleanroom environment (12)

- Scales (11)

- Environmental Monitoring (10)

- Power Monitoring (10)

- Healthcare (9)

- Power Meters (9)

- Software (9)

- cleanroom monitoring systems (9)

- Case Study (8)

- critical environment technologies (8)

- Humidity (7)

- data centers (7)

- particle counter (6)

- pressure transducers (6)

- LITE room pressure monitor (5)

- hardware and software cleanroom monitoring systems (5)

- setra lite (5)

- Compliance (3)

- Video (3)

- hospital spaces (3)

- FAQ & Troubleshooting (2)

- Monitoring Compounding Pharmacies (2)

- Semiconductor Manufacturing (2)

- agencies that monitor pharmacies (2)

- energy (2)

- hvac (2)

- laboratories (2)

- monitor compound pharmacy (2)

- protected environment (2)

- regulatory compliance (2)

- setra lite features (2)

- usp 797 (2)

- Current Sensors and Transducers (1)

- Current Transformers (1)

- Pressure (1)

- aerospace cleanrooms (1)

- cems (1)

- digital transformation (1)

- ipv6 multicast (1)

- ipv6 multicast address (1)

- ipv6 multicast address range (1)

- isolation room pressure monitoring (1)

- multicast address ipv6 (1)

- multicast ipv6 (1)

- operating room (1)

- pharma 4.0 (1)

- pressure sensor (1)

- pressure transducer companies (1)

- semi conductor (1)

- sensors and transducers (1)

- setra pressure transducers (1)

- submetering (1)

- sustainability (1)

- temperature monitor (1)

- temperature monitoring for pharmacies (1)

- transducers (1)

- usp 800 (1)

- water (1)

- what does hvac stand for (1)

- what is a transducer (1)

- what is hvac (1)