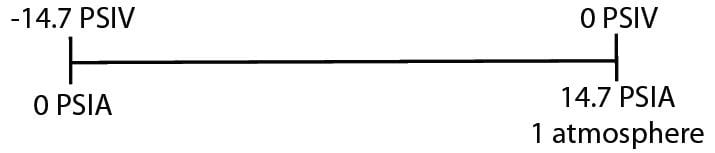

Absolute pressure is measured relative to a full vacuum (0 PSIA = 14.7 PSIV). The electrical output of an absolute pressure transducer is 0 VDC at 0 PSIA and full scale output (typically 5 VDC) at full scale pressure (in PSIA). PSIA (pounds per square inch absolute) is a unit of pressure measured relative to a full vacuum. A vacuum can refer to any pressure between 0 PSIA and 14.7 PSIA.

Setra Blog

Low pressure measurements are required in various applications such as air flow, static duct and cleanroom pressures in HVAC and energy management systems (EMS). Other applications include use in medical instrumentation, environmental pollution control, boil combustion efficiency and a wide variety of research and development requirements. Although the focus will center mainly on air flow and pressure, the same principles

Although there are a variety of methods for leak detection, the most common is pressure decay. Other methods can be time consuming and costly, whereas pressure decay leak detection is a simple test that's sensitive to very small leaks. This method is ideal for high-volume industries that require quick accurate tests within their facility. By pressurizing the unit under test (UUT) and then removing it from the pressure source, any detection of pressure loss is a result of a leak within the UUT. Before performing a pressure decay leak detection test, make sure your system is properly setup. After the system is setup, follow the below steps to test the UUT with a differential pressure transducer.

February 22, 2016

Selecting the Right High Temperature Industrial Pressure Transducer for Liquids or Gases

When selecting an industrial pressure transducer for monitoring high temperature liquids or gases be sure to check the operating temperature range of the transducer, in order to select the correct pressure transducer for these applications.

One factor that should be considered when selecting an industrial pressure transducer for monitoring high temperature liquids or gases is the operating temperature range of the transducer. This specification is included under environmental data on most manufacturers' data sheets.

Any design engineer must seriously consider the manufacturing environment when looking to select a pressure transducer for inclusion within a refrigeration chiller, pump, engine test equipment, or other machinery. The life of a pressure transducer is proportional to the system design and assembly process.

The following steps clearly indicate the exact sequence to properly troubleshoot a Setra 2 wire, mil-amp circuit. You must work with the assumption that either the Setra product or the system & circuitry is bad.

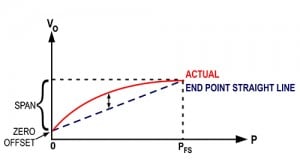

Which method provides better accuracy? Non-linearity as the End Point Method is the relationship of the calibration curve to a specified straight line through its endpoints (i.e. Zero and Full Scale). Best Fit Straight Line (BFSL) method is the relationship of the calibration curve to a calculated straight line that minimizes the error but does not pass through the end points. BFSL method effectively cuts the end point value in half.

If pressure transducers are exposed to a manufacturing environment that exceeds the suppliers specified limits, sensor issues will occur. during storage or assembly. An original equipment manufacturer (OEM) design engineer should take note of the following six conditions while designing a system to be manufactured and shipped to an end-user.

One of the most vital processes within critical environments is the sterilization of medical tools and devices. Patient safety relies heavily on the efficiency and reliability of sterilization devices. Contaminants can become highly resistive to disinfection, which results in the need for high performance sterilization methods that will ensure sterile equipment. Three primary methods of medical sterilization occur from high temperature/pressure and chemical processes.

Subscribe to Our Blog!

Topics

- Critical Environments (182)

- HVAC/R (179)

- General Industrial (153)

- Building Automation (134)

- General Industrial OEM (92)

- Energy Management (85)

- Test and Measurement (66)

- HVAC/R OEM (58)

- Barometric (44)

- Alternative Fuels (42)

- Medical (40)

- Process/Mfg Tank Level (40)

- Water and Wastewater (39)

- OHV (38)

- Oil and Gas (35)

- Industrial Vacuum (29)

- Calibration (25)

- Semiconductor (25)

- Particle Counting (18)

- Cleanroom Monitoring (17)

- Room Pressure Monitoring (16)

- Trade Show (12)

- cleanroom environment (12)

- Scales (11)

- Environmental Monitoring (10)

- Power Monitoring (10)

- Healthcare (9)

- Power Meters (9)

- Software (9)

- cleanroom monitoring systems (9)

- Case Study (8)

- critical environment technologies (8)

- Humidity (7)

- data centers (7)

- particle counter (6)

- pressure transducers (6)

- LITE room pressure monitor (5)

- hardware and software cleanroom monitoring systems (5)

- setra lite (5)

- Compliance (3)

- Video (3)

- hospital spaces (3)

- FAQ & Troubleshooting (2)

- Monitoring Compounding Pharmacies (2)

- Semiconductor Manufacturing (2)

- agencies that monitor pharmacies (2)

- energy (2)

- hvac (2)

- laboratories (2)

- monitor compound pharmacy (2)

- protected environment (2)

- regulatory compliance (2)

- setra lite features (2)

- usp 797 (2)

- Current Sensors and Transducers (1)

- Current Transformers (1)

- Pressure (1)

- aerospace cleanrooms (1)

- cems (1)

- digital transformation (1)

- ipv6 multicast (1)

- ipv6 multicast address (1)

- ipv6 multicast address range (1)

- isolation room pressure monitoring (1)

- multicast address ipv6 (1)

- multicast ipv6 (1)

- operating room (1)

- pharma 4.0 (1)

- pressure sensor (1)

- pressure transducer companies (1)

- semi conductor (1)

- sensors and transducers (1)

- setra pressure transducers (1)

- submetering (1)

- sustainability (1)

- temperature monitor (1)

- temperature monitoring for pharmacies (1)

- transducers (1)

- usp 800 (1)

- water (1)

- what does hvac stand for (1)

- what is a transducer (1)

- what is hvac (1)