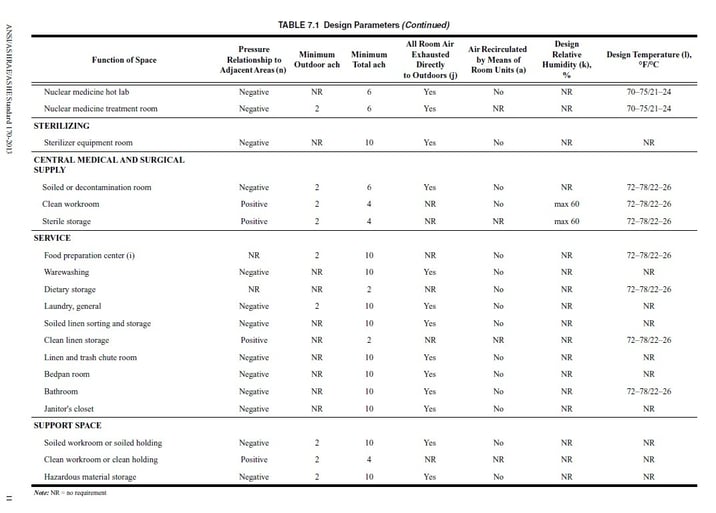

Proper room pressure and airflow are crucial for maintaining critical environments in hospitals. When talking about pressurized hospital spaces, the most well-known are operating rooms and isolation rooms. However, these are not the only two pressurized spaces within a hospital. ASHRAE Standard 170 details 60 different types of rooms in a hospital requiring pressurization. Without proper room pressurization, hospitals put their accreditation by the Joint Commission in jeopardy.

ASHRAE created Standard 170 to serve as a guideline to ensure proper pressurization in these spaces. The minimum pressure required is ±0.01” WC, but most hospitals have pressures between ±0.02” WC and ±0.03” WC to give margin for variation in HVAC system performance. To crudely test the pressurization of a space, hold a tissue at the bottom of the door and see whether the tissue is blown back from or sucked towards the gap. If the tissue is blown back, the room is positively pressurized. If the tissue is sucked towards the gap, the room is negatively pressurized. However, the tissue test only measures the direction of the pressure and cannot indicate whether there is sufficient pressure to meet ASHRAE standards. A more accurate and sophisticated solution would be to install a room pressure monitor, such as the Setra FLEX. A room pressure monitor can immediately sound an audible alarm and even alert the facilities team via the building management system when a room loses pressurization.

|

Negative pressure rooms in hospitals are built to contain dangerous airborne contaminants like tuberculosis and vaporized cough so healthcare staff can safely treat highly infectious diseases. In essence, negative pressure rooms are built to contain contaminants. These spaces include: |

Positive pressure rooms are designed to protect the most vulnerable patients from anything that could compromise their health. In other words, positive pressure rooms are designed to force air contaminants out of a space. These spaces include: |

|

|