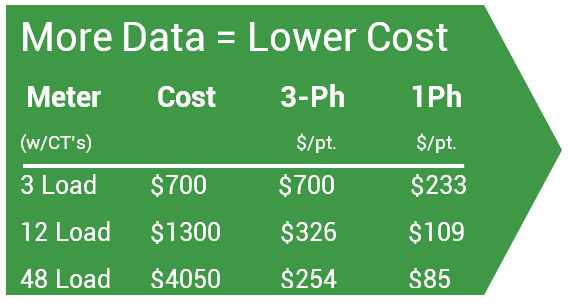

Power meters measure utilities like electric, gas, or water to increase building performance. With a power meter, users can get granular data on the use of energy of a building. Such granularity can reveal any equipment or systems adding to energy waste. Submeters can be used in any type of building, from manufacturing to apartments. Meters make it easy to visualize and optimize energy usage.

Setra Blog

During a disease outbreak, there are several risks dentists encounter. One serious risk is contracting an illness from aerosol particles created during a procedure. Aerosols are splatters, mists, or droplets in the air, and can include saliva, blood, and plaque. Three main sources of airborne contamination in dental offices are dental instrumentation, saliva and respiratory sources, and the operation site. Aerosol particles can be generated with:

It is paramount for schools to put safety first as students prepare to return amidst all the concerns of the coronavirus. An isolation area, separate from any other spaces in the school where medical care is provided, means students displaying symptoms can safely remain isolated until they are picked up.

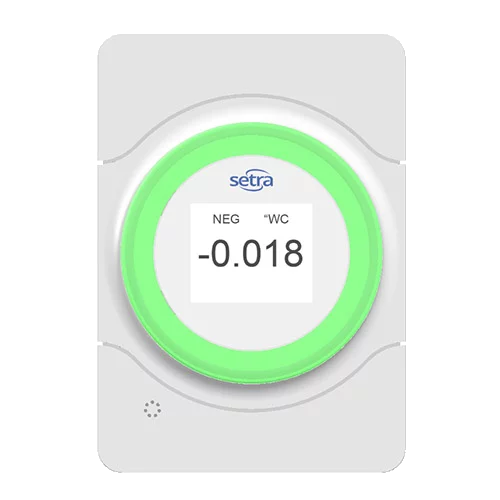

In the wake of the coronavirus, it is essential schools create the safest possible environment before students return. One of the ways to do this is to provide a COVID-19 Related Isolation Space for students displaying symptoms. This isolation area is separate from the nurse's office and any other space where routine medical care is provided. In a negatively pressurized space like this, students with symptoms can safely remain isolated until they are picked up.

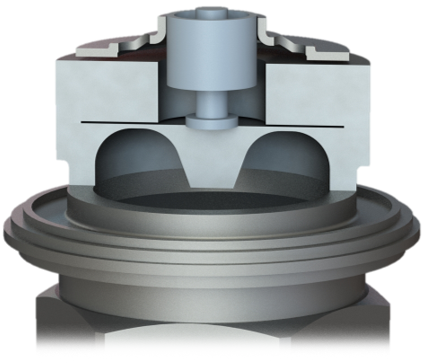

Pressure transducers all have some degree of variation in output caused by changes in temperature. The best way to compensate for such variation is to employ components on the PCBA that respond to temperature. These components can be fixed in value, adjustable like a potentiometer, or feed into a digital circuit.

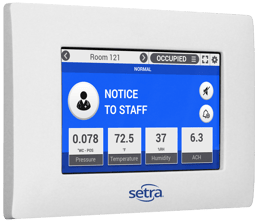

Each space in a hospital requires a different level of monitoring. Some rooms necessitate observing a variety of parameters while others only need an indication of pressure. No matter the requirements, Setra offers a line of pressure monitors to fit any room.

A variety of pressure sensor designs are available today. Two of the most common sensor types are MEMS and capacitive sensors.

Each space in a hospital requires a different level of monitoring. Some rooms necessitate observing a variety of parameters while others only need an indication of pressure. No matter the requirements, Setra offers a line of pressure monitors to fit any room.

In the post COVID-19 world, new applications for negative pressure spaces have begun to emerge and negative pressure ventilation is mentioned throughout OSHA and CDC guidelines. No longer strictly meant for airborne infection isolation rooms in hospitals, negatively pressurizing a space can help businesses and other facilities safely resume operations. These new applications include dental, mortuary, long-term care facilities, and nursing homes. In long-term care facilities, creating an isolation wing using negative pressure can be an effective and efficient way to further reduce the spread of dangerous particles and increase the effectiveness of the isolation. A designated isolation area for suspected or confirmed COVID-19 patients helps limit the possibility of contamination and spread throughout a nursing home or long-term care facility. In spaces like dental offices, that commonly deal with aerosol generating procedures, it is crucial to negatively pressurize certain rooms to prevent the spread of airborne infection.

Many pressure specifications are listed on a sensor's data sheet, but two are often overlooked: proof and burst pressure. Not taking notice of these pressure ranges can lead to sensor failure. These two pressure specifications function as an upper limit for the device's operating range. Although both act as upper limits, proof and burst pressure are not the same.

Subscribe to Our Blog!

Topics

- Critical Environments (182)

- HVAC/R (179)

- General Industrial (153)

- Building Automation (134)

- General Industrial OEM (92)

- Energy Management (85)

- Test and Measurement (66)

- HVAC/R OEM (58)

- Barometric (44)

- Alternative Fuels (42)

- Medical (40)

- Process/Mfg Tank Level (40)

- Water and Wastewater (39)

- OHV (38)

- Oil and Gas (35)

- Industrial Vacuum (29)

- Calibration (25)

- Semiconductor (25)

- Particle Counting (20)

- Cleanroom Monitoring (17)

- Room Pressure Monitoring (16)

- Trade Show (12)

- cleanroom environment (12)

- Scales (11)

- Environmental Monitoring (10)

- Power Monitoring (10)

- Healthcare (9)

- Power Meters (9)

- Software (9)

- cleanroom monitoring systems (9)

- Case Study (8)

- critical environment technologies (8)

- data centers (8)

- Humidity (7)

- particle counter (6)

- pressure transducers (6)

- LITE room pressure monitor (5)

- hardware and software cleanroom monitoring systems (5)

- setra lite (5)

- Compliance (3)

- Video (3)

- hospital spaces (3)

- FAQ & Troubleshooting (2)

- Monitoring Compounding Pharmacies (2)

- Semiconductor Manufacturing (2)

- agencies that monitor pharmacies (2)

- energy (2)

- hvac (2)

- laboratories (2)

- monitor compound pharmacy (2)

- protected environment (2)

- regulatory compliance (2)

- setra lite features (2)

- usp 797 (2)

- Current Sensors and Transducers (1)

- Current Transformers (1)

- Lithium-Ion Battery (1)

- Pressure (1)

- aerospace cleanrooms (1)

- cems (1)

- digital transformation (1)

- ipv6 multicast (1)

- ipv6 multicast address (1)

- ipv6 multicast address range (1)

- isolation room pressure monitoring (1)

- multicast address ipv6 (1)

- multicast ipv6 (1)

- operating room (1)

- pharma 4.0 (1)

- pressure sensor (1)

- pressure transducer companies (1)

- semi conductor (1)

- sensors and transducers (1)

- setra pressure transducers (1)

- submetering (1)

- sustainability (1)

- temperature monitor (1)

- temperature monitoring for pharmacies (1)

- transducers (1)

- usp 800 (1)

- water (1)

- what does hvac stand for (1)

- what is a transducer (1)

- what is hvac (1)