The term vacuum is often misunderstood. Consequently, it is commonly misapplied when discussing pressure measurements and choosing pressure transducers. Pressure is the exertion of force upon an object. However, pressure can be measured in many different ways, depending on the applications.

Vacuum Pressure

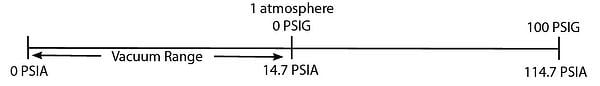

By definition, vacuum is a space that is partially exhausted (as to the highest degree possible) by artificial means (such as an air pump). This definition is referring to a high or hard vacuum. Figure 1 illustrates that relationship of absolute and gauge pressure with 0 PSIA equal to a high or hard vacuum.

Figure 1:

Gauge Pressure

Gauge pressure is pressure measured relative to ambient atmospheric pressure (approximately 14.7 PSIA). It is referred to as pounds per square inch (gauge) or PSIG. The electrical output of a gauge pressure transducer is 0 VDC at 0 PSIG (14.7 PSIA) and full scale output (typically 5 VDC) at full scale pressure (in PSIG).

Absolute Pressure

Absolute pressure is measured relative to high vacuum (0 PSIA). It is referred to as pounds per square inch (absolute) or PSIA. The electrical output of an absolute pressure transducer is 0 VDC at 0 PSIA and full scale output (typically 5 VDC) at full scale pressure (in PSIA).

Vacuum can refer to any pressure between 0 PSIA and 14.7 PSIA and consequently must be further defined. For applications concerned with measuring vacuum pressures over this full range, two different approaches are often taken.

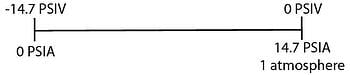

Figure 2:

Vacuum pressure is measured relative to ambient atmospheric pressure. It is referred to as pounds per square inch (vacuum) or PSIV. The electrical output of a vacuum pressure transducer is 0 VDC at 0 PSIV (14.7 PSIA) and full scale output (typically 5 VDC) at full scale vacuum, 14.7 (0 PSIA).

The vacuum pressure transducer gives an increased positive voltage output proportional to decreasing pressure (increasing vacuum). The absolute pressure transducer gives an increased positive voltage output proportional to increasing pressure (decreasing vacuum).

Example

Vacuum Transducer

Range: 0 to 14.7 PSIV

Output: 0 to 5 VDC

Absolute Transducer

Range: 0 to 14.7 PSIA

Output: 0 to 5 VDC

Differential Pressure

Vacuum also is often referred to as negative pressure (or soft vacuum). This occurs when the application requires monitoring both decreases in pressure below atmospheric pressure and increases in pressure above atmospheric bidirectional differential pressure.

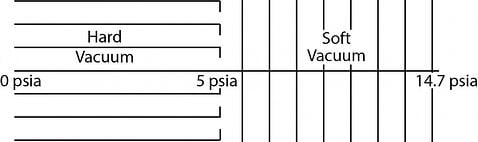

Figure 3:

Here differential pressure is pressure measured relative to a reference pressure. It is referred to as pounds per square inch (differential) or PSID. If the reference pressure is one atmosphere the differential pressure range is equal to gauge pressure range. The electrical output of a bidirectional differential pressure transducer is typically 0 VDC at one atmosphere with increased positive voltage output proportional to increased positive pressure and increased negative voltage output proportional to increased negative pressure.

Example

Bidirectional Differential Pressure Transducer

Range: 0 to ±5 PSID

Output: 0 to ±2.4 VDC

Bidirectional differential pressure transducers are used for soft or low vacuum measurements (typically greater than 5 PSIA) while low absolute pressure transducers are used for hard or high vacuum measurements (typically less than 5 PSIA).

Figure 4 illustrates soft and hard vacuums.

Figure 4:

Setra's Vacuum Sensors

Setra's vacuum pressure transducers are built with capacitive sensing technology and are used in a wide variety of applications. Accurate, reliable, and stable, Setra's Model 206, 209, and 210 have been successfully integrated into applications from injection molding to semiconductor manufacturing. The AXD is the latest addition to this product family and is intended as a robust solution for the most demanding applications.

For more information, take a look at our INDUSTRIAL PRESSURE SENSOR CATALOG